Preparation and application of super-water-whitening-resistant succinate surfactant

A surfactant and white succinate technology, applied in adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problem that surfactants cannot meet both environmental protection and APEOFREE indicators, and cannot meet the water whitening resistance of emulsions at the same time issues of sex and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

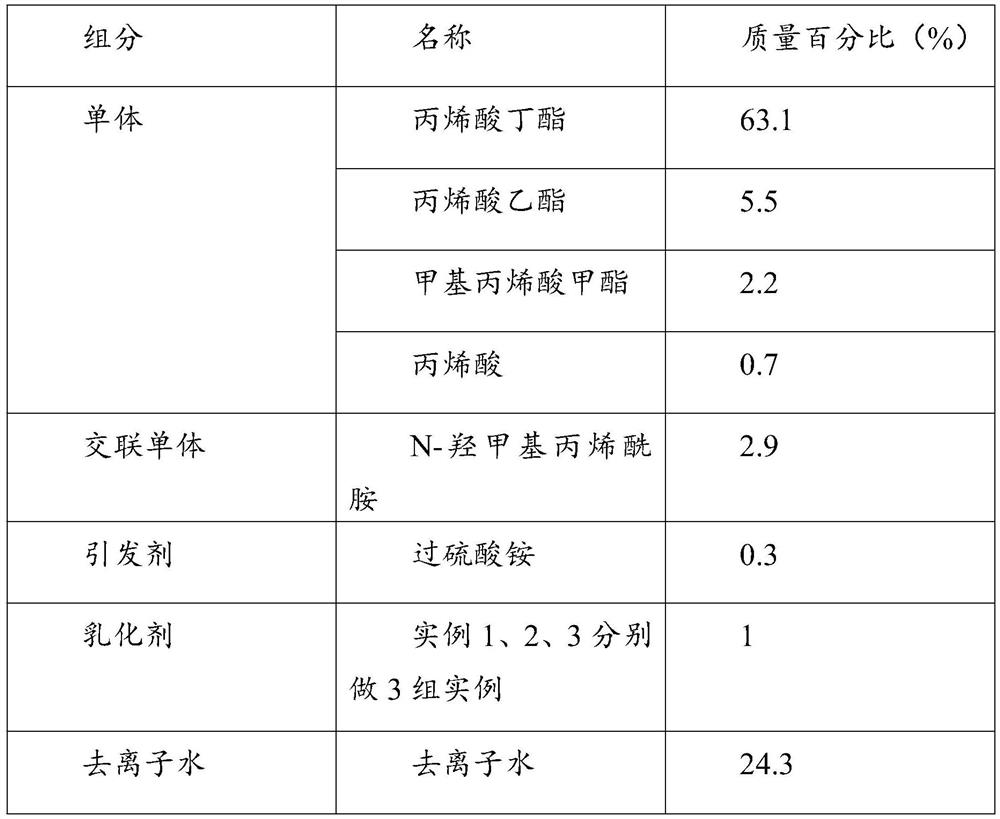

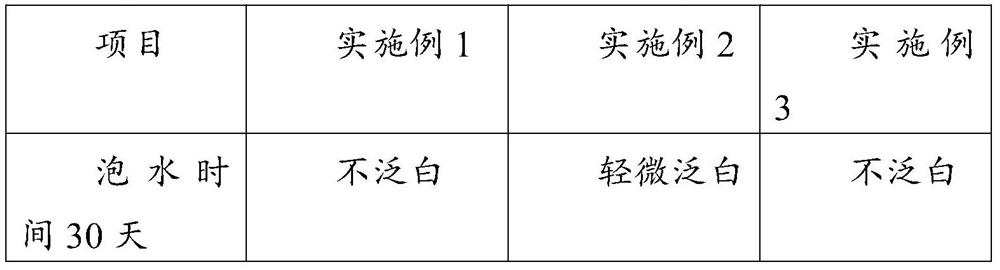

Examples

preparation example Construction

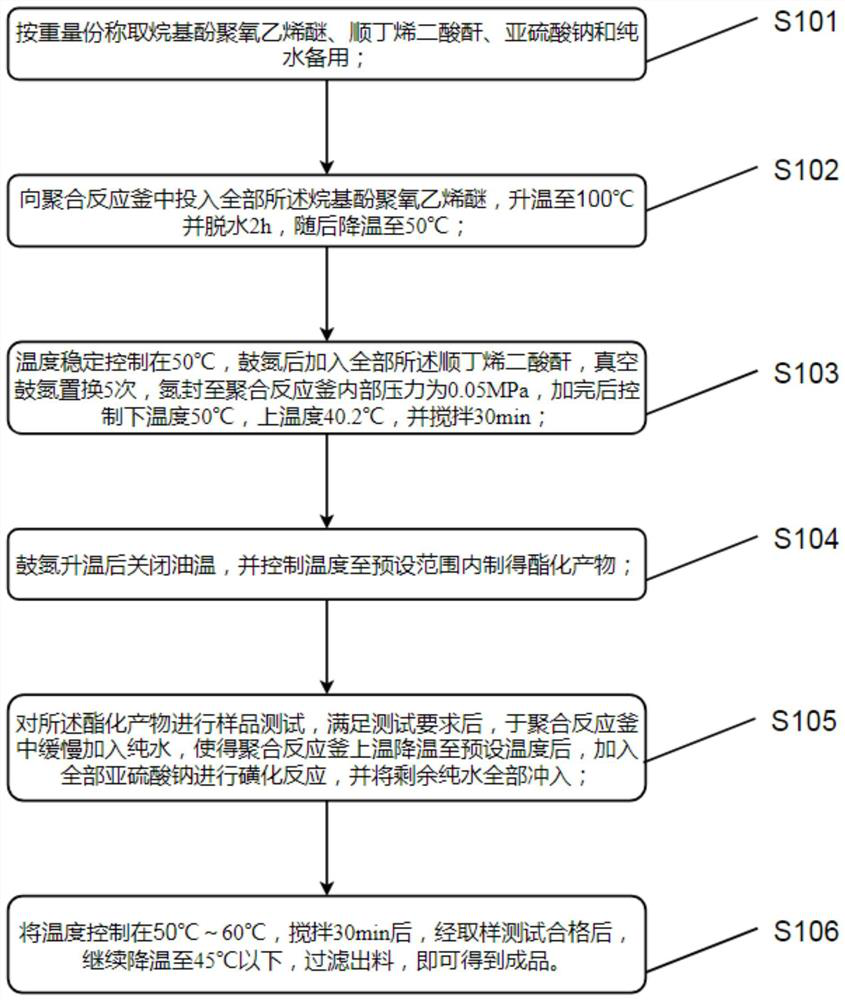

[0044] The preparation method of described super water-resistant white succinate surfactant comprises the steps:

[0045] S101: Weigh the alkyl polyoxyethylene ether, maleic anhydride, sodium sulfite and pure water by weight for subsequent use;

[0046] S102: Put all the alkyl polyoxyethylene ethers into the polymerization reactor, raise the temperature to 100°C and dehydrate for 2 hours, then cool down to 50°C;

[0047] S103: The temperature is stably controlled at 50°C. After blowing nitrogen, all the maleic anhydride is added, replaced by vacuum blowing nitrogen for 5 times, and nitrogen is sealed until the internal pressure of the polymerization reactor is 0.05 MPa. After the addition, the temperature at the bottom of the reactor is controlled to be 50°C, the temperature at the top of the reactor was 40.2°C, and stirred for 30 minutes;

[0048] S104: Turn off the oil temperature after the nitrogen drum is heated up, and control the temperature to a preset range to obtain ...

Embodiment 1

[0070] Example 1: 180 parts of alkyl polyoxyethylene ether, 55 parts of maleic anhydride, 65 parts of sodium sulfite, and 700 parts of pure water;

[0071] Specifically, the alkyl polyoxyethylene ether is 3EO C12-14 alcohol polyoxyethylene ether, and its water content is below 1‰;

[0072] Specifically, the preparation method is as follows:

[0073] According to the formula in claim 1 or 2, the raw materials are respectively taken for subsequent use;

[0074] Put 180 parts of alkyl polyoxyethylene ether into the polymerization reactor, raise the temperature to 100°C for dehydration for 2 hours, and then lower the temperature to 50°C;

[0075] The temperature is stably controlled at 50°C. After blowing nitrogen, add maleic anhydride accounting for 55 parts of the total weight, vacuum blow nitrogen for 5 times, and nitrogen seal to 0.05MPa. After the addition, the temperature at the bottom of the reactor is 50°C. The temperature is 40.2°C, stirring for 30 minutes;

[0076] St...

Embodiment 2

[0080] Embodiment 2: 190 parts of alkyl polyoxyethylene ether, 50 parts of maleic anhydride, 65 parts of sodium sulfite, 695 parts of pure water;

[0081] Specifically, the alkyl polyoxyethylene ether is 5EO C12-14 alcohol polyoxyethylene ether, and its water content is below 1‰;

[0082] Specifically, the preparation method is as follows:

[0083] According to the formula in claim 1 or 2, the raw materials are respectively taken for subsequent use;

[0084] Put 190 parts of alkyl polyoxyethylene ether into the polymerization reactor, heat up to 100°C for dehydration for 2 hours, and then cool down to 50°C;

[0085] The temperature is stably controlled at 50°C. After blowing nitrogen, add maleic anhydride accounting for 50 parts of the total weight. Vacuum nitrogen blowing is replaced 5 times, and the nitrogen is sealed to 0.05MPa. After the addition, the temperature at the bottom of the reactor is 50°C. The temperature is 40.2°C, stirring for 30 minutes;

[0086] Start blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com