Preparation method of temperature-sensitive hydrogel and temperature-sensitive hydrogel product prepared by preparation method

A temperature-sensitive, hydrogel technology, applied in the field of smart new materials, can solve the problems of cytotoxicity, breakage, and time-consuming, and achieve the effects of simple and easy preparation method, industrial transformation, and wide source of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

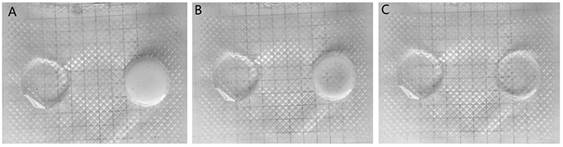

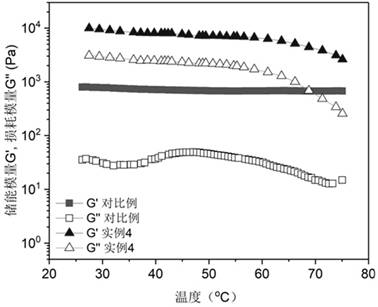

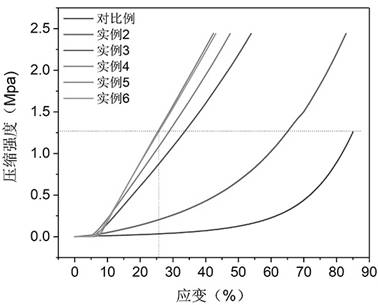

Image

Examples

Embodiment 1

[0022] A method for preparing a temperature-sensitive hydrogel, the specific steps are as follows:

[0023] (1) Add 20 g of polyvinyl alcohol (PVA) into 180 g of water, stir and heat up to 90° C. until a homogeneous and transparent polyvinyl alcohol solution with a mass fraction of 10% is obtained;

[0024] (2) The polyvinyl alcohol solution is transferred to the mould, using 60 Coγ-rays were irradiated, and the irradiation dose was 30kGy to obtain a polyvinyl alcohol hydrogel with a thickness of 2mm;

[0025] (3) Put the polyvinyl alcohol hydrogel prepared in step (2) into an aqueous solution of gallic acid, soak for 24 hours, take it out after soaking, and obtain a temperature-sensitive hydrogel; wherein, the amount of gallic acid in the aqueous solution of gallic acid The mass fraction is 0.1%.

Embodiment 2

[0027] The content of Example 2 is basically the same as that of Example 1, except that the mass fraction of gallic acid in the gallic acid aqueous solution described in step (3) is 0.2%.

Embodiment 3

[0029] The content of Example 3 is basically the same as that of Example 1, except that the mass fraction of gallic acid in the gallic acid aqueous solution described in step (3) is 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com