Preparation method and application of conjugated organic framework/perfluorinated sulfonic acid resin composite proton exchange membrane

A perfluorosulfonic acid resin and proton exchange membrane technology, which is applied to fuel cell components, fuel cells, electrochemical generators, etc., can solve the problems of low proton conductivity and mechanical properties of perfluorosulfonic acid proton exchange membranes , to achieve the effect of uniform COF/perfluorosulfonic acid composite membrane, low raw material price and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

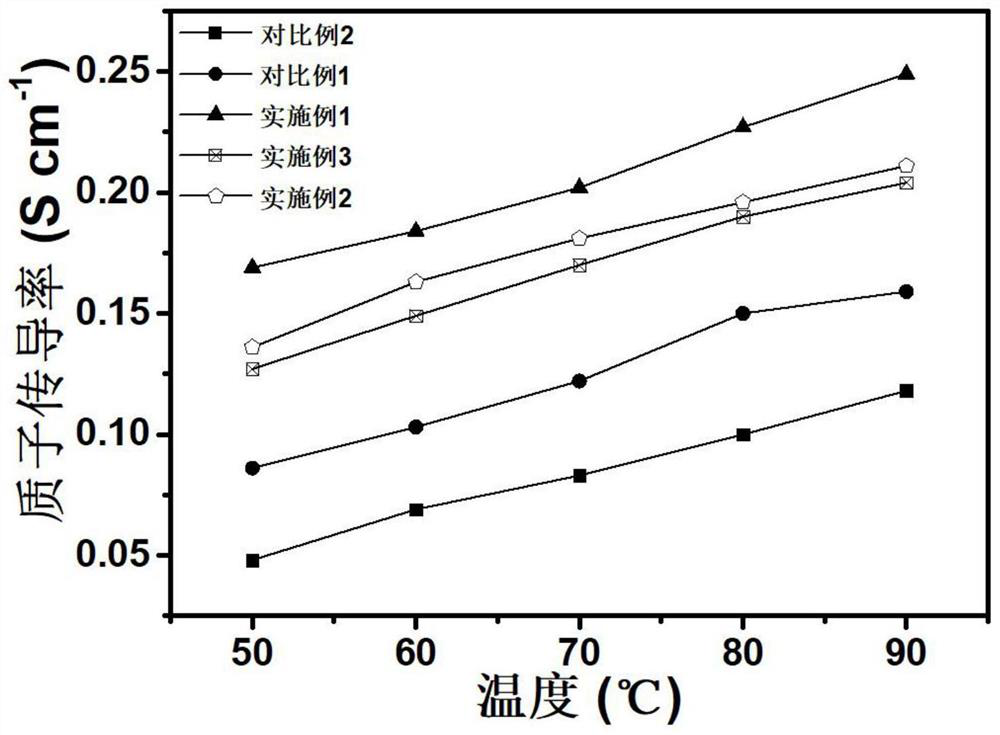

Embodiment 1

[0036] Embodiment 1: The preparation method of a conjugated organic framework / perfluorosulfonic acid resin composite proton exchange membrane of this embodiment is carried out according to the following steps:

[0037] Step 1: Dissolve 7g of hexachlorocyclotrimeric phosphazene and 10.5g of melamine in 120mL of N,N-dimethylformamide, then add 32g of triethylamine and 0.19g of tetrabutylammonium bisulfate, and reflux at 80°C React for 70 hours, centrifuge after the reaction, wash with water, and vacuum dry at 80°C for 12 hours to obtain a conjugated organic framework material;

[0038] Step 2: ultrasonically disperse 2 g of the conjugated organic framework material obtained in step 1 in 133 mL of nitrogen-methylpyrrolidone to obtain a dispersion, add 20 g of perfluorosulfonic acid resin powder to the dispersion, and stir magnetically until a uniform emulsion is formed;

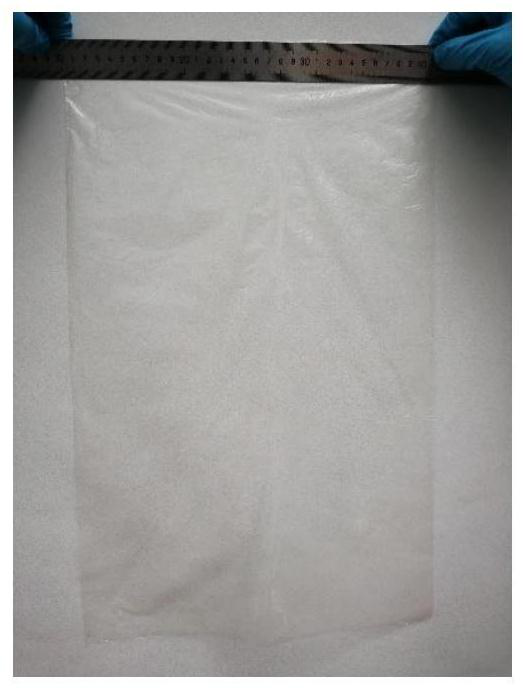

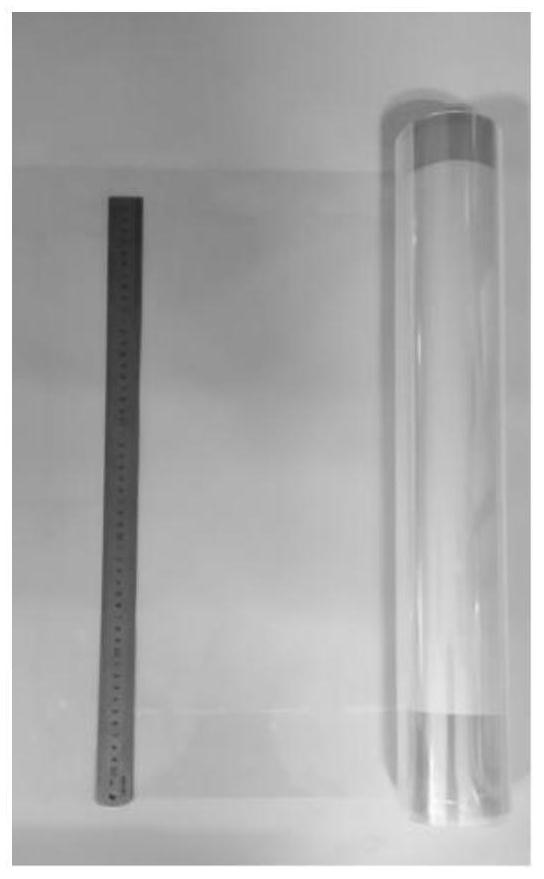

[0039] Step 3: Scrape-coat the emulsion obtained in step 2 on a glass plate, first air-dry at 80°C for 10 hou...

Embodiment 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the dosage of the conjugated organic framework material in step 2 is 1 g. All the other steps and parameters are the same as in Example 1.

Embodiment 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the dosage of the conjugated organic framework material in step 2 is 0.4 g. All the other steps and parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com