Control method of hypereutectoid rare earth steel rail network carbide

A network carbide and control method technology, applied in the field of metallurgical materials, can solve the problems of reducing grain boundary energy and rail toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

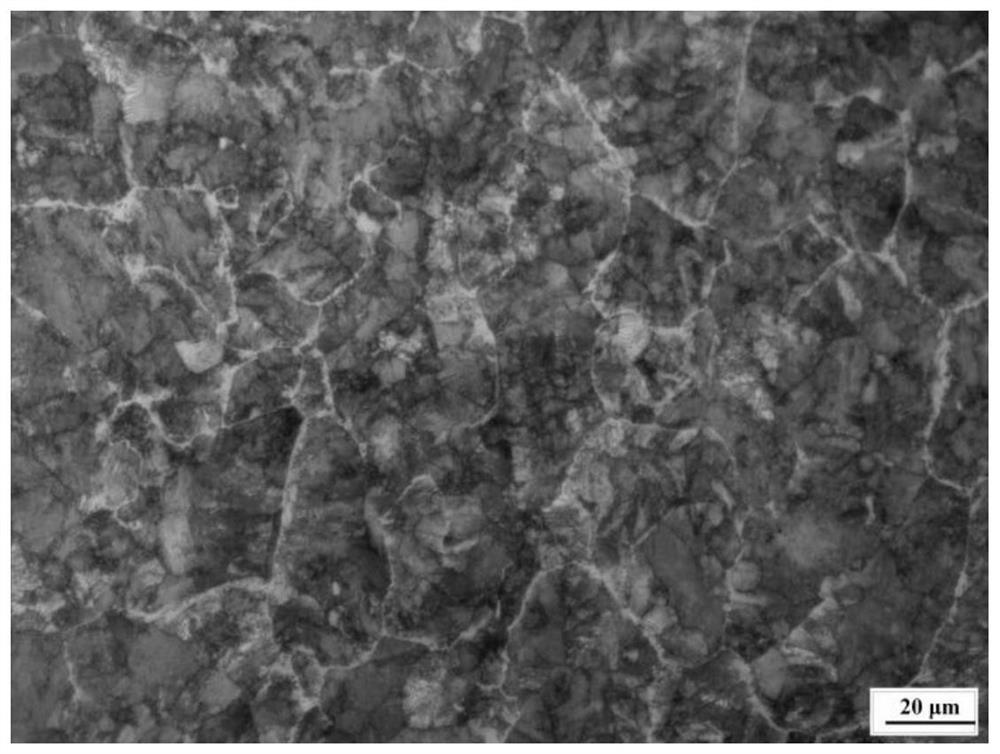

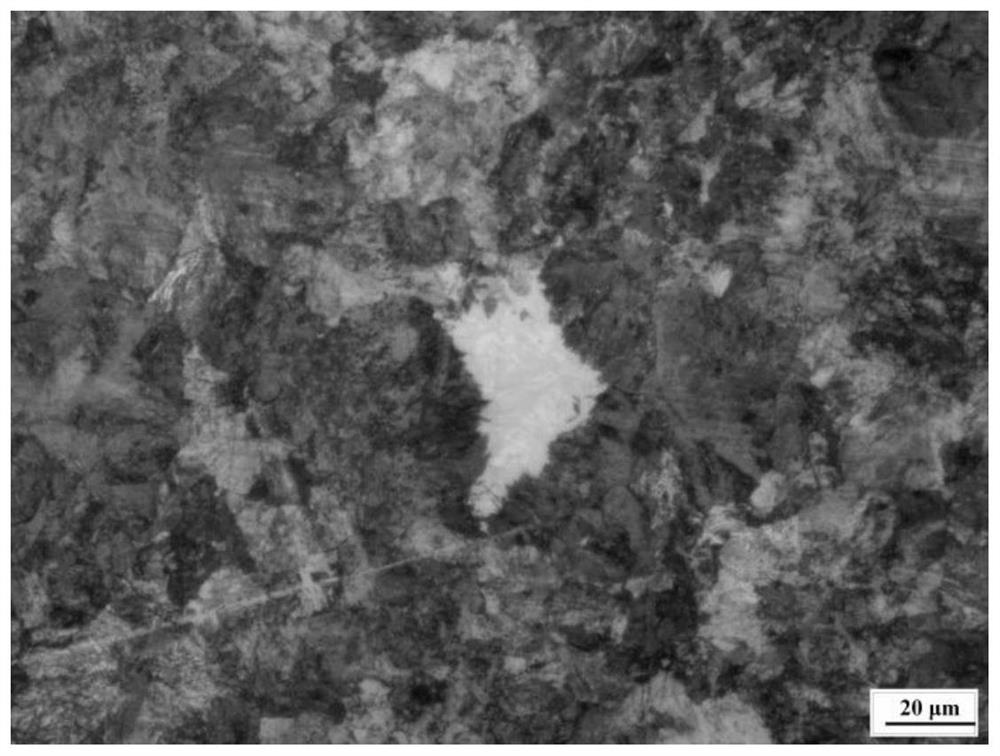

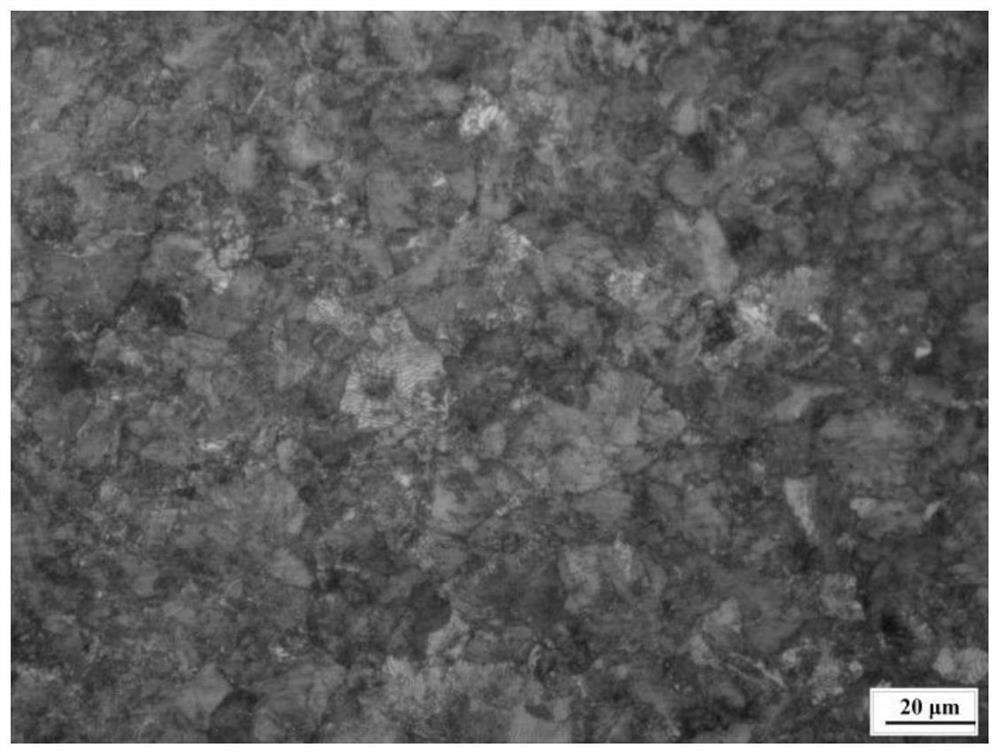

Image

Examples

Embodiment 1

[0018] After the final rolling, the rail directly enters the cooling bed and is cooled at room temperature at a cooling rate of 0.5°C / s. The rail is directly cooled from 930°C to room temperature, and the mechanical properties of the rail are tested.

Embodiment 2

[0020] After the final rolling of the rail, it directly enters the online heat treatment production line for accelerated cooling. The cooling method is jet cooling. The temperature of the rail entering the quenching line is 742°C. The cooling speed of the first and second stages of the rail head is controlled at 8°C / s. After rapid cooling in stage 1 and cooling stage 2, the temperature of the rail head reaches 560°C, and then the rail continues to be rapidly cooled in stage 3 and stage 4, and the cooling rate is reduced. After the 4th stage of cooling, the rails exit the on-line heat treatment unit. At this time, the temperature of the rail head is controlled at 450°C, and the rails exit the quenching line to cool naturally to room temperature. Check the final mechanical properties of the rail.

Embodiment 3

[0022] After the final rolling of the rail, it directly enters the online heat treatment production line for accelerated cooling. The cooling method is air spray cooling. The temperature of the rail entering the quenching line is 752°C. The cooling speed of the first and second stages of cooling is controlled at 6.5°C / s. After rapid cooling in stage 1 and cooling stage 2, the temperature of the rail head reaches 584°C, and then the rail continues to be rapidly cooled in stage 3 and stage 4, and the cooling rate is reduced. After the 4th stage of cooling, the rails exit the on-line heat treatment unit. At this time, the temperature of the rail head is controlled at 505°C, and the rails exit the quenching line to cool naturally to room temperature. Check the final mechanical properties of the rail.

[0023] Table 1 Test results of rail mechanical properties at different cooling rates

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com