Chlorine dioxide gold leaching method for preparing leaching agent in ore pulp

A chlorine dioxide and pulp technology, applied in the field of metallurgy, can solve the problems of toxic bromide volatilization, high leaching cost, and difficulty in industrial application, and achieve economic benefits, improve direct leaching rate, and simplify the gold leaching operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

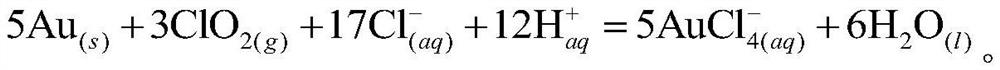

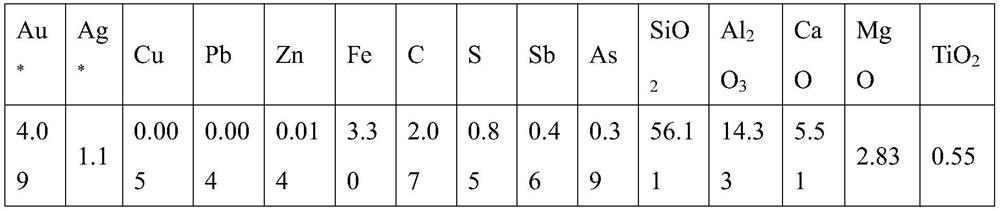

[0039] The ore sample used in this example is a Carlin-type gold deposit in Gansu. This type of gold ore is mainly composed of pyrite, stibnite, and arsenopyrite, and metal sulfides are scattered in the ore. Gold is usually wrapped in sulfide minerals in the form of fine particles or submicroscopic particles, and the gold is directly cyanide leached. The rate is 39%, which belongs to refractory ore, and its chemical composition is shown in Table 1.

[0040] Table 1: Raw ore multi-element analysis results (%, * g / t)

[0041]

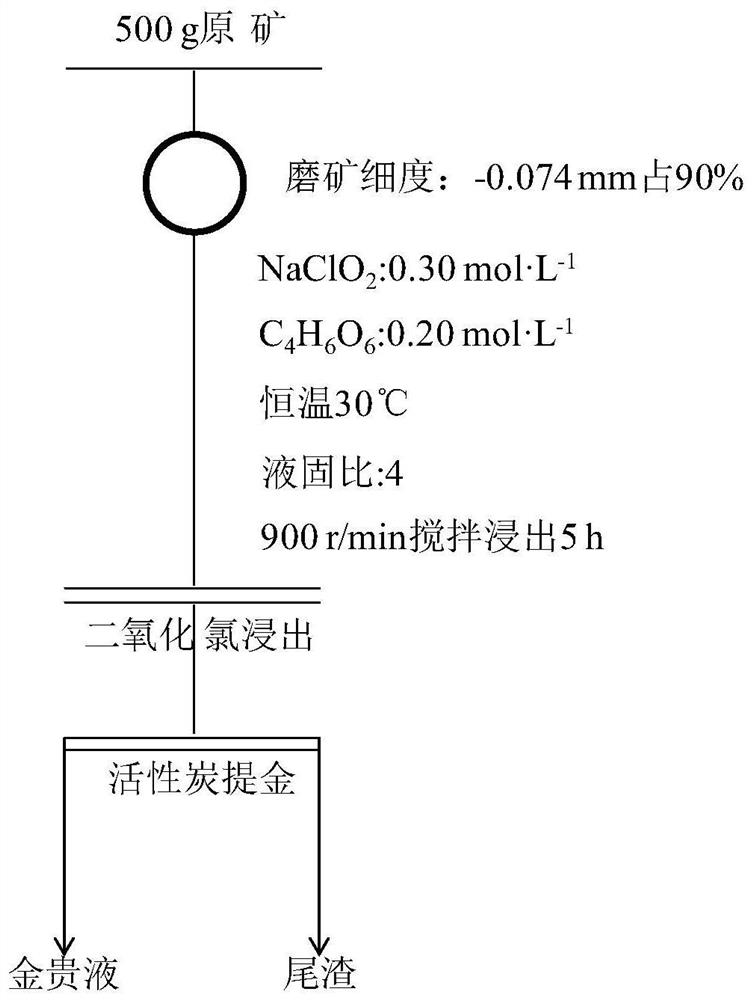

[0042] Finely grind the above-mentioned gold ore until particles with a particle size of no more than 0.074mm account for 90%, add sulfuric acid at a concentration of 0.625mol / L, tartaric acid at a concentration of 0.20mol / L, sodium chloride at a concentration of 0.05mol / L, and sodium chlorite at a concentration of 0.30mol / L, the liquid-solid mass ratio is 4:1, and the leaching rate of gold can reach 91.02% under the condition of stirring speed of 90...

Embodiment 2

[0044] The type of ore sample used in this example is carbonaceous refractory gold ore, and its chemical composition is shown in Table 2. Due to the gold-intercepting effect of organic carbon, the direct cyanide leaching rate of this ore is only 9.29%, which is a refractory gold ore.

[0045] Table 2: Multi-element analysis results of a carbonaceous gold ore (%, * g / t)

[0046]

[0047] Roast the gold ore to be leached in an oxygen-enriched environment at 700°C for 1 hour to remove the gold-intercepting carbon. After the roasted slag is finely ground, the slurry is adjusted, and chlorine dioxide generators (sodium chlorite NaClO 2 , concentration 0.12mol / L) and activator (citric acid C 6 h 8 o 7 , concentration 0.10mol / L), the generated chlorine dioxide is dissolved in the pulp, and immediately reacts with gold minerals to realize gold leaching. The specific process is as follows: finely grind 500g of roasted slag until the particle size is less than 0.074mm, accounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com