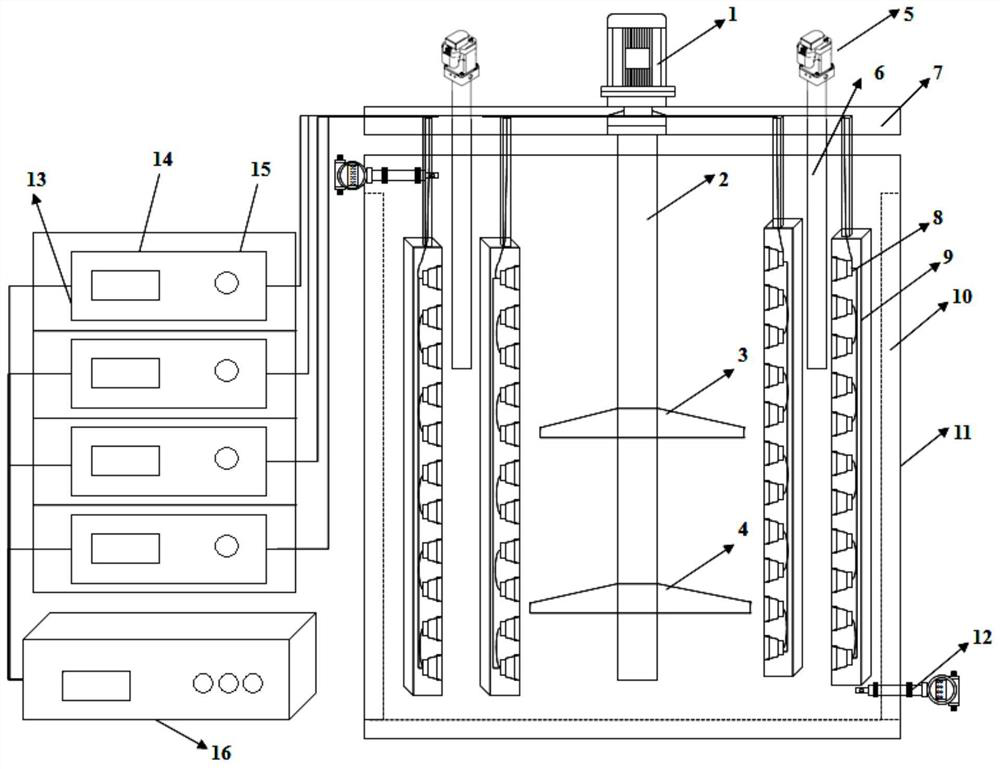

Method for leaching germanium in zinc oxide smoke through ultrasonic enhancement

An ultrasonic strengthening, zinc oxide technology, applied in the field of germanium leaching, can solve the problems of reducing germanium precipitation loss, poor germanium leaching kinetics, low germanium extraction rate, etc., to avoid germanium precipitation loss, improve germanium leaching rate, and improve germanium extraction. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: a method of ultrasonically strengthening germanium leaching in zinc oxide fume, adopts the device of ultrasonically intensifying germanium leaching in zinc oxide fume, and the concrete steps are as follows:

[0052] a. The zinc oxide dust containing 20wt% of zinc, 1wt% of iron and 200g / t of germanium was added to the leaching tank equipped with sulfuric acid solution (concentration of 100g / L), stirred at a temperature of 50°C (stirring rate was 200rpm) ) leaching for 1min to obtain the leaching system A, and the pH value of the system in the leaching tank is monitored by a pH meter during the leaching process; wherein the zinc oxide soot is obtained from the fuming and volatilization of zinc acid leaching residues, and more than 90% of the zinc in the soot exists in the form of zinc oxide, The mass content of soluble iron accounts for 66.06% of iron, and germanium exists in the form of germanate, germanium sulfide, germanosilicate and square GeO 2 , the ma...

Embodiment 2

[0056] Embodiment 2: a method of ultrasonically strengthening germanium leaching in zinc oxide fume, adopts the device for ultrasonically strengthening germanium leaching in zinc oxide fume, and the concrete steps are as follows:

[0057] a. Zinc oxide dust containing 54.14wt% of zinc, 1.21wt% of iron and 418g / t of germanium was added to the leaching tank equipped with sulfuric acid solution (concentration of 160g / L), and stirred at a temperature of 60°C (stirring rate 350rpm) leaching for 2min to obtain leaching system A, during the leaching process, the pH value of the system in the leaching tank was monitored by a pH meter; wherein the zinc oxide fume was obtained from the fume and volatilization of zinc acid leaching residues, and more than 93.27% of the zinc in the fume was in the form of zinc oxide Exist, the mass content of soluble iron accounts for 66.05% of iron, and germanium exists in the form of germanate, germanium sulfide, germanosilicate and square GeO 2 , the m...

Embodiment 3

[0061] Embodiment 3: a method for ultrasonically intensifying germanium leaching in zinc oxide fume, adopts the device for ultrasonically intensifying germanium leaching in zinc oxide fume, and the concrete steps are as follows:

[0062] a. Add the zinc oxide dust containing 60wt% zinc, 10wt% iron and 5000g / t germanium into the leaching tank equipped with sulfuric acid solution (concentration is 180g / L), stir at a temperature of 80°C (stirring speed is 500rpm) ) leaching 5min to obtain leaching system A, and the pH value of the system in the leaching tank is monitored by a pH meter during the leaching process; wherein the zinc oxide fume is obtained from the fume volatilization of zinc acid leaching residues, and more than 95% of the zinc in the fume exists in the form of zinc oxide, The mass content of soluble iron accounts for 66.08% of iron, and germanium exists in the form of germanate, germanium sulfide, germanosilicate and square GeO 2 , the mass content of germanium in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com