Ultrahigh-voltage coaxial thin-film capacitor, parallel capacitor device and application in high-energy electric pulse energy storage equipment

A film capacitor and ultra-high voltage technology, applied in the direction of film/thick film capacitors, fixed capacitor electrodes, fixed capacitor shells/packages, etc., can solve the problems of reduced connection reliability, limited energy storage, unfavorable capacitor replacement and increase or decrease, etc. Achieve the effect of reducing loop inductance and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

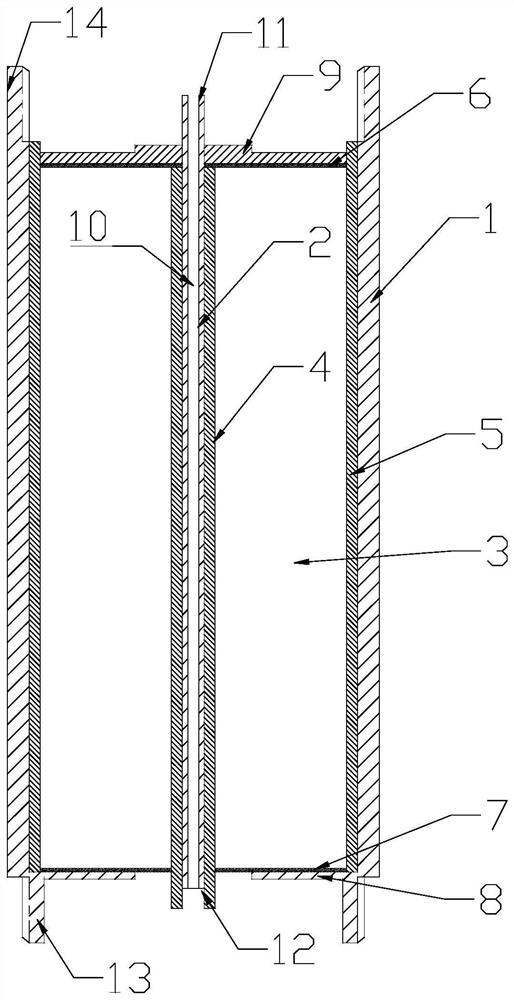

[0035] Such as figure 1 An ultra-high voltage coaxial film capacitor is shown, the coaxial capacitor includes a metal outer shell 1, a conductive shaft core 2 and a capacitor body 3, the conductive shaft core 2 is arranged inside the metal outer shell 1 by a thick-walled copper tube, and It is arranged coaxially with the metal outer shell 1, and the capacitor body 3 is arranged in a cylindrical shape in the cylindrical cavity formed by the conductive shaft core 2 and the metal outer shell 1, and a first insulation is provided between the capacitor body 3 and the conductive shaft core 2. The isolation layer 4, the capacitor body 3 and the metal outer shell 1 are provided with a second insulating isolation layer 5; the first insulating isolation layer 4 is sleeved on the outside of the conductive shaft core 2, and the upper end surface of the first insulating isolation layer 4 is in contact with the capacitor body The end faces of 3 are flush, and the conductive layer 6 on the p...

Embodiment 2

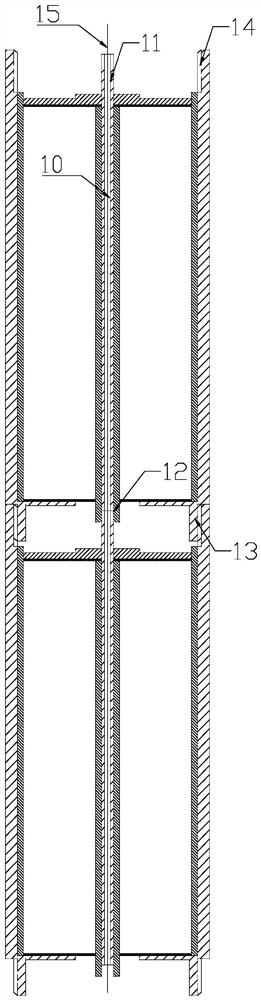

[0040] Such as image 3 A parallel coaxial capacitor device is shown, the device includes a plurality of capacitors shown in Embodiment 1, the plurality of capacitors are spliced up and down, and the metal shells 1 of the upper and lower adjacent two capacitors are upper and lower Splicing with each other, the upper and lower conductive shaft cores 2 of the two capacitors are spliced with each other to form a parallel capacitor circuit. The metal shells 1 of the two adjacent capacitors on the upper and lower sides are spliced with each other through male and female connectors, and the conductive shaft cores 2 of the two adjacent capacitors on the upper and lower sides are spliced with each other through the male and female connectors. The outer end of the threaded male head 13 is processed with a packing groove for installing a sealed high-pressure fluid, and the inner side of the threaded section of the threaded female head 14 is processed with a sealing surface. And...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap