Method for controlling aperture size of via hole on TFT substrate

A technology of aperture size and via hole, which is applied in the field of display screens, can solve the problems of enlarged aperture, fluctuation, and influence on the electrical characteristics of lap resistance, etc., to achieve enhanced control, ensure lap resistance and electrical characteristics, and avoid backing phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

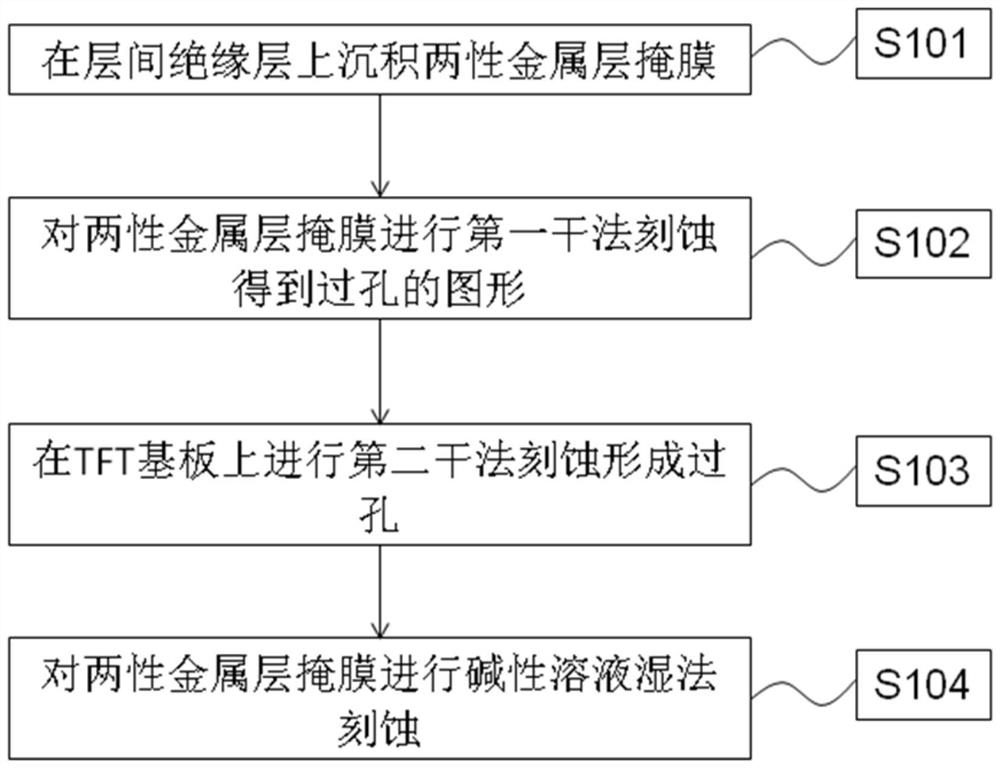

[0026] Such as figure 1 As shown, a method for controlling the size of the via hole on the TFT substrate, comprising:

[0027] S101: Depositing an amphoteric metal layer mask on the interlayer insulating layer;

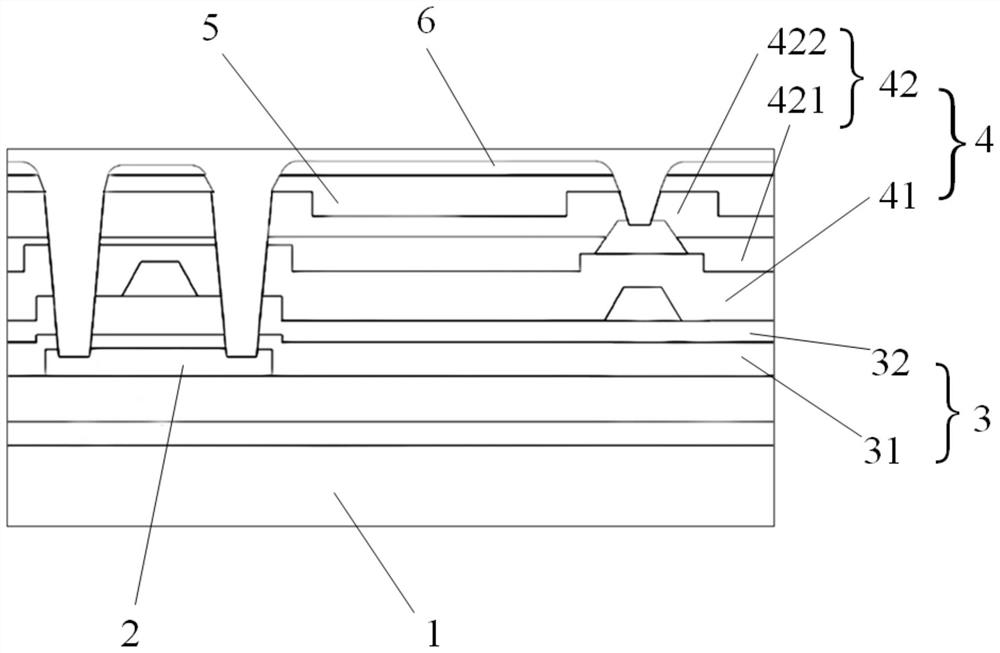

[0028] The amphoteric metals include aluminum and zinc, and aluminum has a price advantage in raw material cost. In this embodiment, preferably, the amphoteric metal is aluminum, and the amphoteric metal layer mask is an aluminum layer mask. Such as figure 2 As shown, the TFT substrate structure from top to bottom is photoresist 6, aluminum layer mask 5, SiN x The second interlayer insulating layer 422, SiO x The second interlayer insulating layer 421, the first interlayer insulating layer 41, SiN x Gate insulating layer 32, SiO x The gate insulating layer 31, the active layer 2, and the aluminum layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com