CuO-coated Cu-BTC composite electrode with rod-shaped structure and preparation method thereof

A composite electrode and rod-shaped structure technology, applied in the direction of negative electrodes, structural parts, battery electrodes, etc., can solve the problems of difficult application of full batteries, low first-cycle Coulombic efficiency, and limited commercial prospects, etc., to achieve high specific capacity and improve Coulombic efficiency , High Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

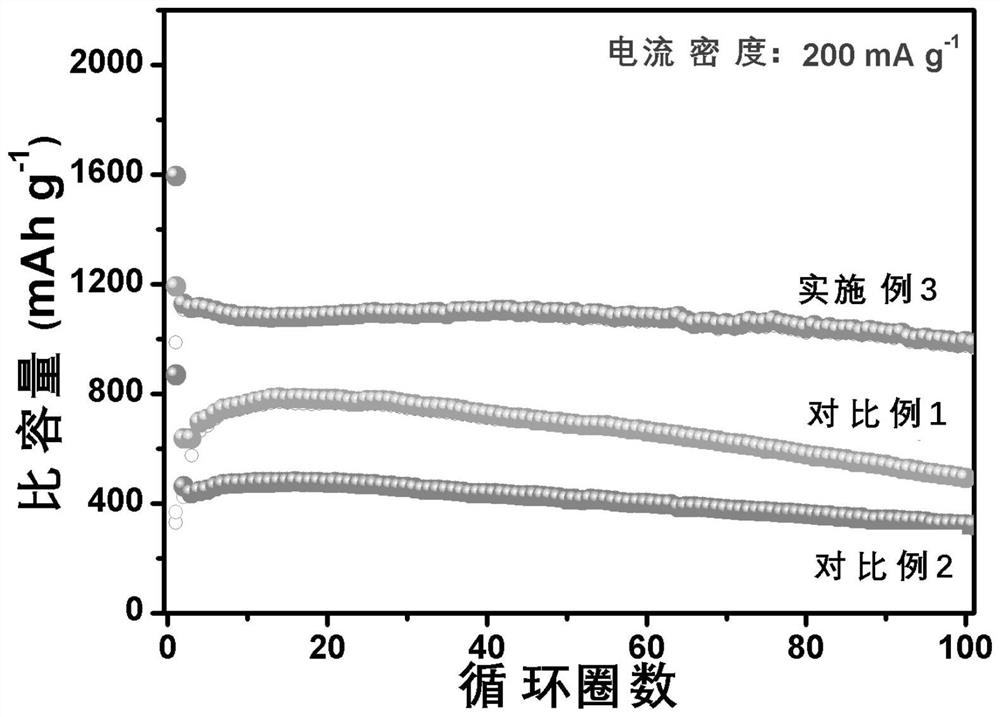

Embodiment 1

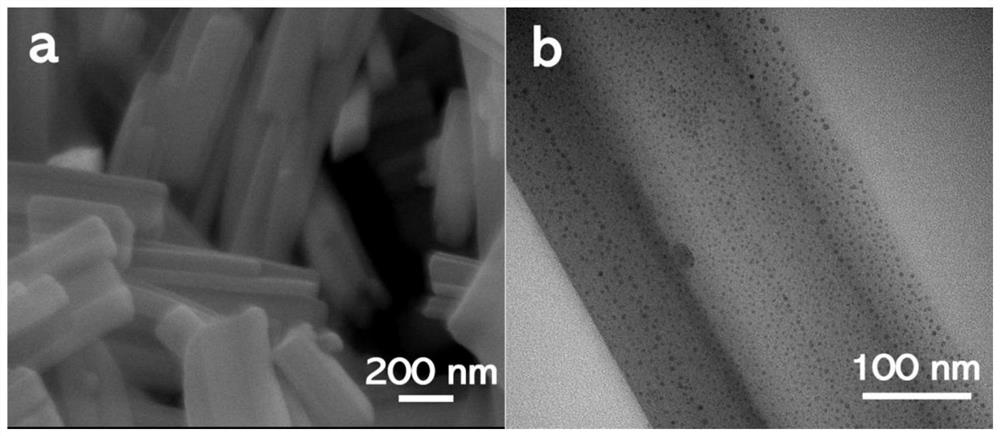

[0022] A rod-shaped CuO@Cu-BTC composite electrode, Cu-BTC accounts for 86.40 wt% of the total mass of the composite electrode, CuO accounts for 13.60 wt% of the total mass of the composite electrode, and the average particle size of CuO is 6.98 nm . Its preparation method comprises the following steps:

[0023] (1) Preparation of CuO nanoparticles:

[0024] Take 0.300 mol L respectively -1 CuSO 4 ·5H 2 O and Na 2 CO 3 80 mL of aqueous solution was recorded as solutions A and B respectively, and the solutions A and B were heated to 50 °C at the same time. Under ultrasonic conditions, add solution B to solution A until all green precipitates are formed. The product was collected by centrifugation, washed three times with deionized water at 60 °C, and dried at 70 °C for 6 h. Finally, the product was decomposed in a muffle furnace preheated at 600 °C for 2 h to obtain copper oxide nanoparticles.

[0025] (2) Solution configuration:

[0026] Take 12 g H 3 Put BTC into 2...

Embodiment 2

[0030] A rod-shaped CuO@Cu-BTC composite electrode, Cu-BTC accounts for 89.25 wt% of the total mass of the composite electrode, CuO accounts for 10.75 wt% of the total mass of the composite electrode, and the average particle size of CuO is 6.92 nm . Its preparation method comprises the following steps:

[0031] (1) Preparation of CuO nanoparticles:

[0032] Take 0.8 mol L respectively -1 CuSO 4 ·5H 2 O and Na 2 CO 3 150 mL of aqueous solution, respectively recorded as solutions A and B, while heating solutions A and B to 70 °C. Under ultrasonic conditions, add solution B to solution A until all green precipitates are formed. The product was collected by centrifugation, washed three times with deionized water at 60 °C, and dried at 70 °C for 6 h. Finally, the product was decomposed in a muffle furnace preheated at 700 °C for 3 h to obtain copper oxide nanoparticles.

[0033] (2) Solution configuration:

[0034] Take 18 g H 3 Put BTC into 300 mL of ethanol and water...

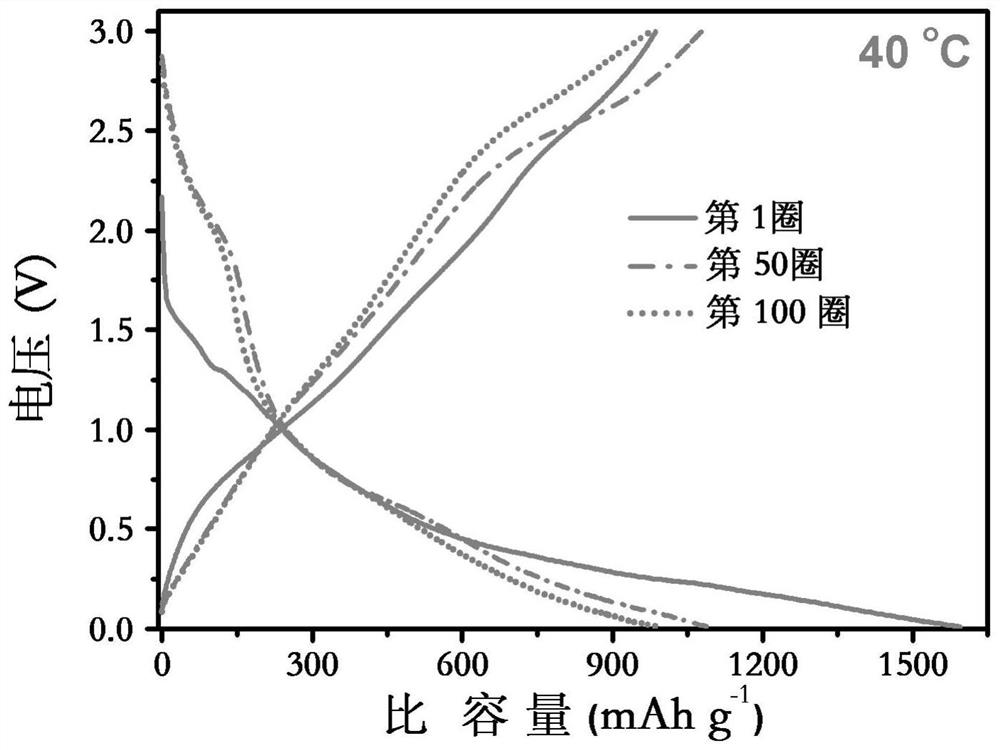

Embodiment 3

[0038] A rod-shaped CuO@Cu-BTC composite electrode, Cu-BTC accounts for 91.69 wt% of the total mass of the composite electrode, CuO accounts for 8.31 wt% of the total mass of the composite electrode, and the average particle size of CuO is 4.78 nm . Its preparation method comprises the following steps:

[0039] (1) Preparation of CuO nanoparticles:

[0040] Take 0.5 mol L respectively -1 CuSO 4 ·5H 2 O and Na 2 CO 3 Aqueous solution 100 mL, respectively recorded as solution A and B, while heating solutions A and B to 60 ℃. Under ultrasonic conditions, add solution B to solution A until all green precipitates are formed. The product was collected by centrifugation, washed three times with deionized water at 60 °C, and dried at 70 °C for 6 h. Finally, the product was decomposed in a muffle furnace preheated at 600 °C for 3 h to obtain copper oxide nanoparticles.

[0041] (2) Solution configuration:

[0042] Take 15.8 g H 3 Put BTC into 200 mL of ethanol and water mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com