Austenitic stainless steel hydrogen embrittlement-resistant weldment for hydrogen energy equipment and preparation method

A technology of austenitic stainless steel and stainless steel is applied in the field of austenitic stainless steel anti-hydrogen embrittlement weldments for hydrogen energy equipment and its preparation, which can solve the problem of high production cost of weldments and difficulty in determining the improvement effect of the anti-hydrogen embrittlement performance of weldments. Issues not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In a second aspect, the present invention provides a method for preparing an austenitic stainless steel anti-hydrogen embrittlement weldment for hydrogen energy equipment, the preparation method comprising the following steps:

[0044] Position and place two stainless steel plates to be welded in the welding environment, and use flat plate butt welding;

[0045] The welding torch equipped with stainless steel electrodes is welded to two stainless steel plates to be welded by melting tungsten argon arc welding. The welding current is 195-205A, the welding voltage is 25-27V, and the welding speed is 33-37cm / min.

[0046] Further, the material of the stainless steel electrode is E308.

Embodiment 1

[0061] Using 304 austenitic stainless steel as the base material, the experimental base metal was plate butt welded by melting electrode tungsten argon arc welding. The welding current was 200A, the welding voltage was 25V, the welding speed was 35cm / min, and the weldment was air-cooled to room temperature. , inspect the appearance of the weld, and conduct welding defect detection to confirm that the welding quality of the weldment is good;

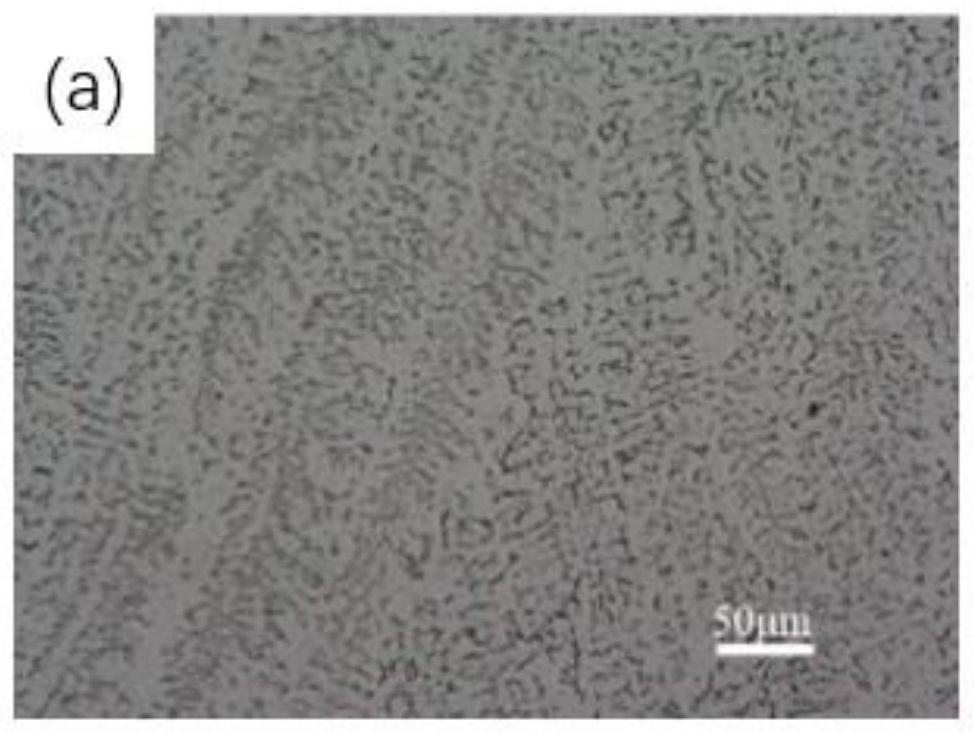

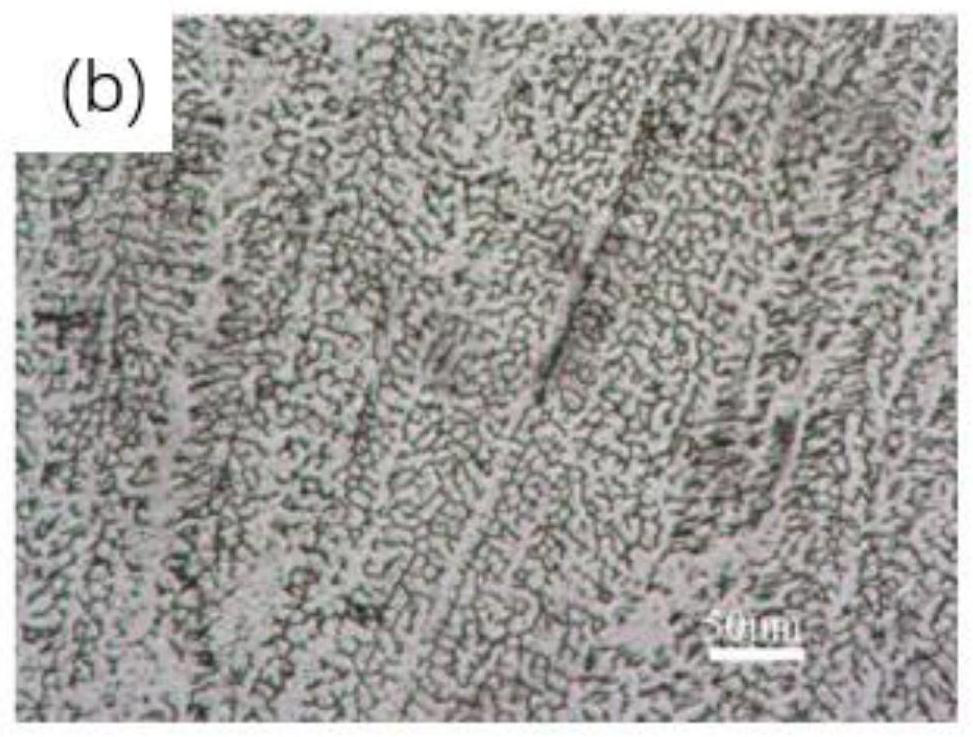

[0062] Cut a 10mm*10mm*1mm weld thin-section sample, after polishing, observe the microstructure of the sample, as shown in Figure 2(c), the ferrite is distributed in a dendritic form;

[0063] The SKPFM atomic force microprobe technology was used to conduct a comparison experiment of the potential distribution of the sample before and after hydrogen charging, as shown in Figure 3(c);

[0064] Cut the standard tensile sample, after polishing and hydrogen charging, the slow strain rate experiment is carried out on the sample, as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com