Water-reducing polycarboxylate superplasticizer with vinyl ether ester mixed structure and preparation method thereof

A hybrid structure, vinyl ether technology, applied in the field of concrete admixtures, can solve problems such as high temperature and inapplicability, and achieve the effects of improving workability, reducing steric resistance, and improving wrapping and entanglement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

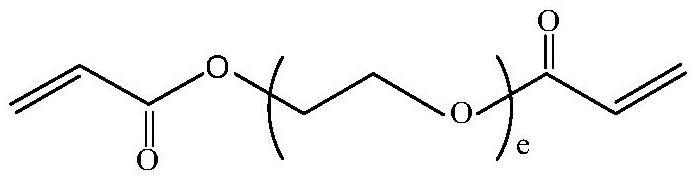

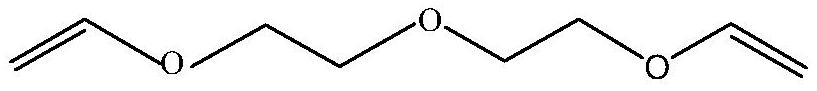

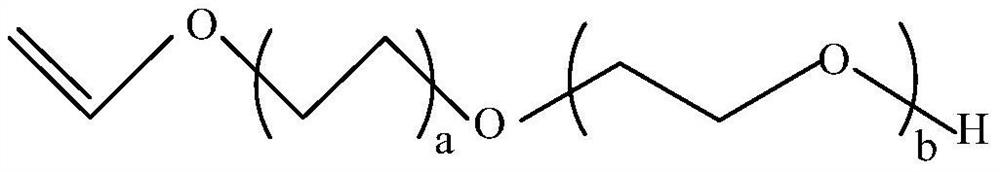

[0037] Add 100g of ethylene glycol monovinyl polyethylene glycol ether, 20g of polyethylene glycol diacrylate and 50g of water into the reactor, control the temperature at 15°C, place the reactor under ultraviolet light irradiation, and stir At the same time, 2,4,6 (trimethylbenzoyl)diphenylphosphine oxide aqueous solution, mercaptoacetic acid aqueous solution, and A solution were added dropwise within 1.5h respectively, and after the addition was completed, the insulation was kept for 0.5h to obtain the reaction product; Adjust the pH to 6.5 with sodium hydroxide to obtain a polycarboxylate water reducer with a mixed structure of vinyl ether ester;

[0038] Wherein, 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide aqueous solution is 2.2g of 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide dissolved in 150g water, mercaptoacetic acid The aqueous solution is 0.5g mercaptoacetic acid dissolved in 150g water, the A solution is 10g acrylic acid, 5g cross-linking monomer diethylen...

Embodiment 2

[0042] Add 100g of butanediol monovinyl polyethylene glycol ether, 20g of polyethylene glycol diacrylate and 50g of water into the reactor, control the temperature at 20°C, place the reactor under ultraviolet light irradiation, and stir At the same time, 2,4,6-trimethylbenzoyl ethyl phosphonate aqueous solution, mercaptoethanol aqueous solution, acrylic acid and cross-linking monomer blended aqueous solution were added dropwise within 1.5h, and after the dropwise addition, it was incubated for 0.5h to obtain the reaction product; the pH of the reaction product is adjusted to 7.0 with sodium hydroxide to obtain a polycarboxylate water reducer with a mixed structure of vinyl ether ester;

[0043] Among them, the aqueous solution of ethyl 2,4,6-trimethylbenzoylphosphonate is 2.0g of ethyl 2,4,6-trimethylbenzoylphosphonate dissolved in 150g of water, and the aqueous solution of mercaptoethanol is 0.5g Mercaptoethanol was dissolved in 150g of water, and the blended aqueous solution o...

Embodiment 3

[0047] Add 100g of hexanediol monovinyl polyethylene glycol ether, 10g of polyethylene glycol diacrylate and 50g of water into the reactor, control the temperature at 20°C, place the reactor under ultraviolet light irradiation, and stir At the same time, 2,4,6 (trimethylbenzoyl)diphenylphosphine oxide aqueous solution, mercaptoacetic acid aqueous solution, acrylic acid and cross-linking monomer blended aqueous solution were added dropwise within 1.5h, and the temperature was kept for 0.5h after the dropwise addition. Obtain a reaction product; adjust the pH of the reaction product to 6.5 with sodium hydroxide to obtain a polycarboxylate water reducer with a mixed structure of vinyl ether ester;

[0048] Wherein, 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide aqueous solution is 2.5g of 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide dissolved in 150g water, mercaptoacetic acid The aqueous solution is 0.5 g of mercaptoacetic acid dissolved in 150 g of water, and the blended ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com