Continuous industrial-scale microwave extraction method

An extraction method and an industrial-scale technology, applied in the field of continuous industrial-scale microwave extraction, can solve problems such as the inability to achieve industrial-scale extraction, failure to meet market demand, waste of raw materials, etc., to improve material utilization, reduce energy consumption, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

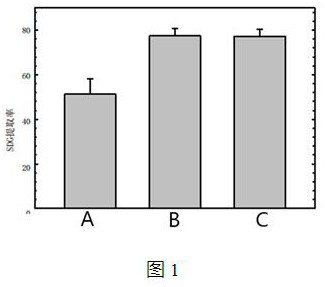

Embodiment 1

[0015] A continuous industrial-scale microwave extraction method is provided, comprising the steps of: mixing flax biomass with a solvent, microwave action in a 915 MHz continuous flow extractor, and continuously adding The flax biomass and the ethanol solution with a mass fraction of 70%, specifically adding the flax biomass to the 915 MHz continuous flow extractor per hour is 85 kg, and the ethanol solution is added in an amount of 1 kg per hour. The flax biomass is added to 5L ethanol solution, and generally the mixture addition of the flax biomass and the ethanol solution is added in batches, and the interval time of each addition is equal, and the addition amount of each addition is equal, and the interval time of each addition is 20 minutes, that is, flax biomass and solvent stay in a 915 MHz continuous flow extractor for 20 minutes to obtain the extract antioxidant SDG. The 915 MHz continuous flow extractor in the present invention is a commercially available extractor,...

Embodiment 2

[0017] A continuous industrial-scale microwave extraction method is provided, comprising the steps of: mixing flax biomass with a solvent, microwave action in a 915 MHz continuous flow extractor, and continuously adding The flax biomass and the ethanol solution with a mass fraction of 65%, specifically adding the flax biomass to the 915 MHz continuous flow extractor per hour, the amount of the flax biomass is 75kg, and the amount of the ethanol solution is 1kg per hour. The flax biomass is added to 6L ethanol solution. Generally, the mixture addition of the flax biomass and the ethanol solution is added in batches, and the interval time of each addition is equal, and the addition amount of each addition is equal. The interval time of each addition is 15 minutes, that is, flax biomass and solvent stay in a 915 MHz continuous flow extractor for 15 minutes to obtain the extract antioxidant SDG.

Embodiment 3

[0019] A continuous industrial-scale microwave extraction method is provided, comprising the steps of: mixing flax biomass with a solvent, microwave action in a 915 MHz continuous flow extractor, and continuously adding The flax biomass and the ethanol solution with a mass fraction of 75%, specifically adding the flax biomass to the 915 MHz continuous flow extractor per hour, the amount of the flax biomass is 100kg, and the amount of the ethanol solution is 1kg per hour. The flax biomass is added to 4L ethanol solution, and generally the mixture addition of the flax biomass and the ethanol solution is added in batches, and the interval time of each addition is equal, and the addition amount of each addition is equal, and the interval time of each addition is 25 minutes, that is, flax biomass and solvent stay in a 915 MHz continuous flow extractor for 25 minutes to obtain the extract antioxidant SDG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com