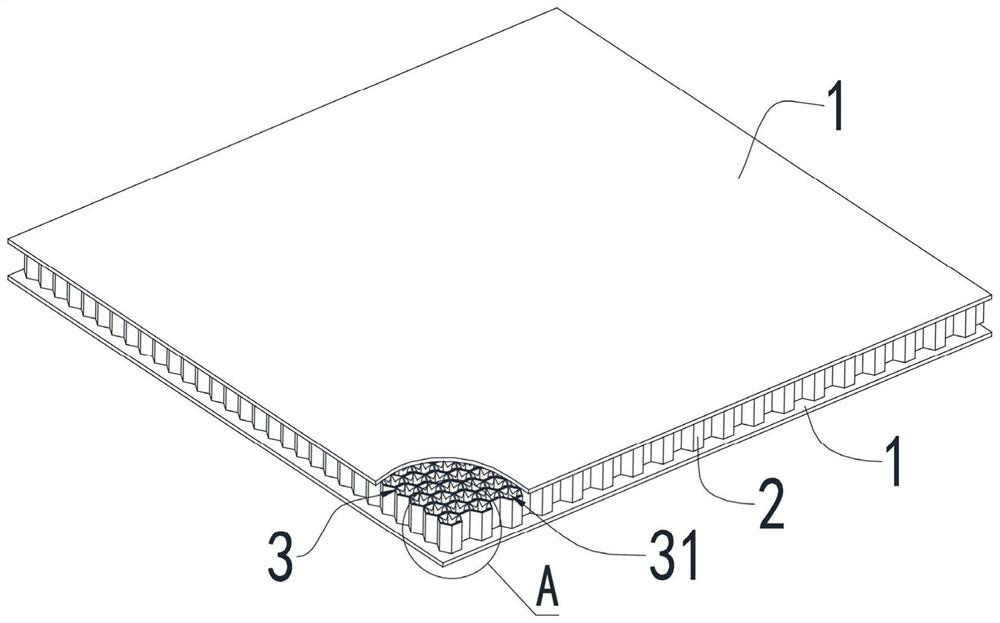

Honeycomb sandwich preparation method for improving honeycomb sandwich bonding force and honeycomb sandwich

A technology of honeycomb interlayer and adhesive force, which is applied in the field of honeycomb interlayer, can solve problems such as defects, low bonding efficiency, and glue spots at the bonding position, achieve high bonding strength and mechanical properties, avoid forming defects, and improve bonding quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

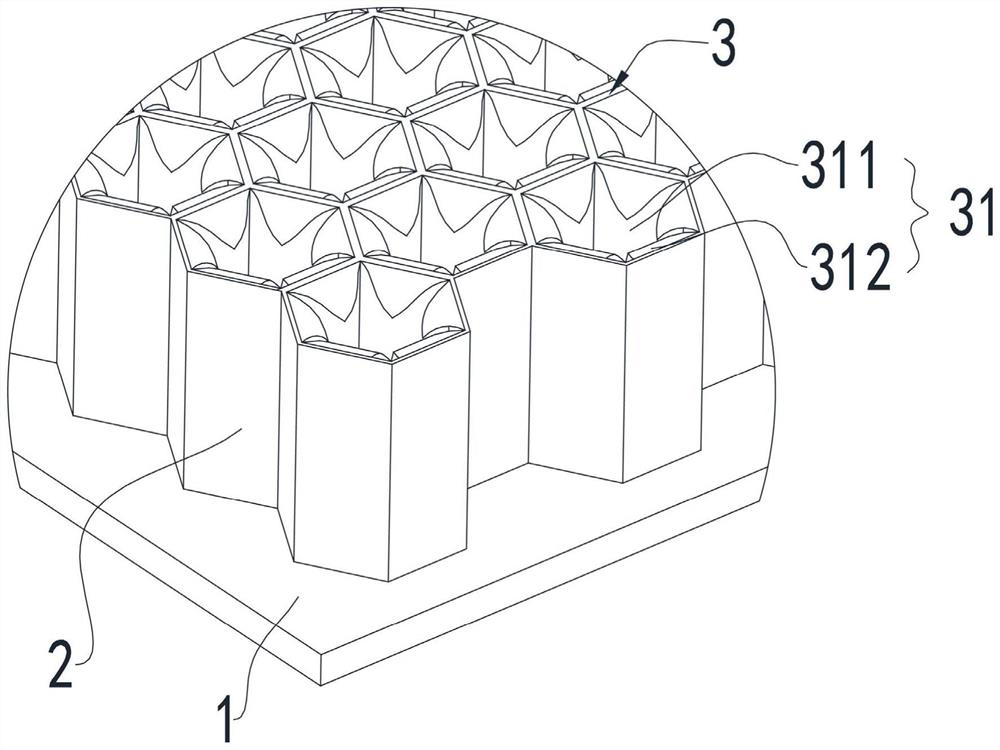

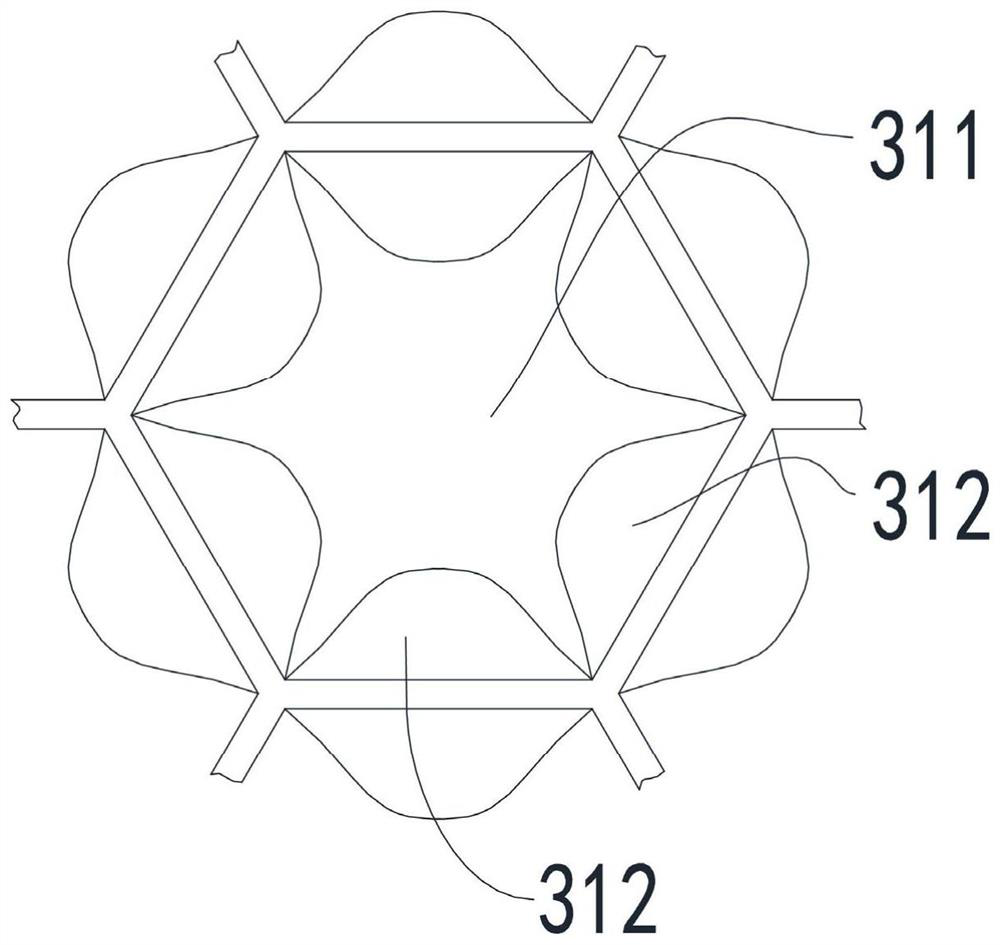

Embodiment 1

[0062] A cyanate quartz fabric panel / aramid paper honeycomb sandwich article, the cross-sectional shape of the honeycomb unit is a positive hexagon, and the honeycomb core body is known to be 2.5-3.0MPa, using Xantu developed by New Zealand Revolution Fibres. The LAYR nanofiber membrane is used as a transferee organic soft fiber layer, and the hexa tool (while the six cutting tools) is used in accordance with the distribution cycle of the honeycomb unit, the processing is completed, and the laying order is sequentially panel prepared. / After the film / processed nanofiber membrane / honeycomb core / processed nanofiber membrane / film / panel prepreg, in the heat pressing tank, in 0.3 MPa pressure. After the curing is completed, it is processed into 60 * 60 standard test blocks and performs a flat pull strength test. The test results show that the pull-up intensity of the honeycomb interlayer prepared by the present preparation method is 2.3-2.9 MPa, and the destruction mode is...

Embodiment 2

[0067] A aluminum honeycomb sandwich article, the skin thickness is 1 mm, the core layer thickness is 7mm, and the mesh size is 3.2mm, the wall thickness is 0.1 mm as the core material, since the use ambient temperature is high, the cyanate film, It is known that the honeycomb core body body is 3.5-4.2 MPa, and a aramid melt-free nonwoven fabric having a surface density of 20g / square meter is used, and the six-flowered tool is processed according to the distribution cycle of the honeycomb unit, and the processing is completed. The level sequentially is aluminum skin / film / processed aramid meltblown nonwoven fabric / aluminum honeycomb core layer / after processing aramid meltblown nonwoven fabric / film / aluminum skin, in the hot press tank Curing at 0.3 MPa. After the curing is completed, it is processed into 60 * 60 standard test blocks and performs a flat pull strength test. The test results show that the pull-up strength of the honeycomb sandwich sheet prepared by the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com