Water recovery type NaBH4 hydrogen production device

A technology of hydrogen production equipment and water recovery, which is applied in the field of hydrogen production equipment, can solve problems such as no advantages, and achieve the effect of increasing hydrogen storage density and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

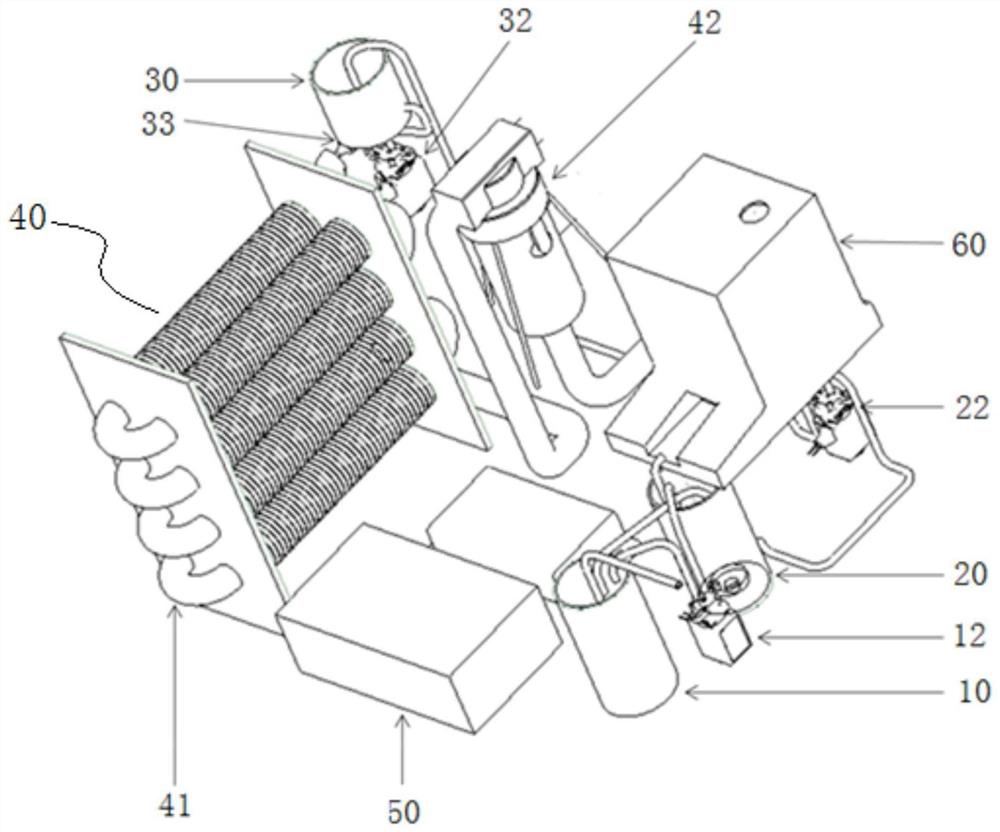

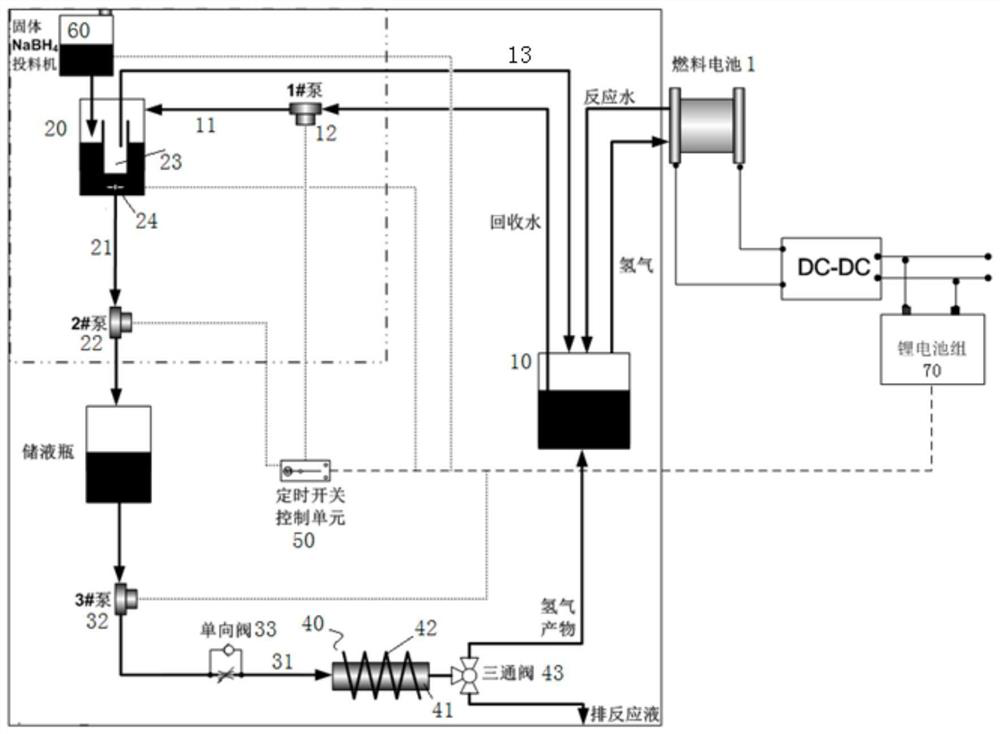

[0073] Such as figure 2 As shown, a water recovery NaBH is provided 4 Hydrogen production unit, at first inject initial water in recovery container 10, place solid NaBH in solid feeder 60 4 . Calculated on the basis of fuel cell supporting equipment running at 500W for 5 hours, 200g of hydrogen, NaBH 4 Solid 925g, if prepared as 12% NaBH in mass percentage 4 Solution, solid feeder NaBH 4 Block feeding speed 3.2g / min, NaBH 4 The block is a tablet of fixed size and weight compressed by a tablet machine, about 200mg / tablet.

[0074] The lithium battery pack is powered on, the solid feeder 60, the vibration motor, and the timing switch control unit 50 start to work. At the same time, the first pump 12 transports the water in the recovery container 10 to the liquid distribution container 20 at a flow rate of 23.47g / min, and the solid NaBH 4 Mix the dosing solution.

[0075] When the set time is up, the second pump 22 and the third pump 32 are turned on. The second pump 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com