Pyrogenic separation method of chloride

A separation method, chloride technology, applied in the direction of alkali metal chloride, ammonium chloride, zinc halide, etc., can solve the problems of high production cost, incomplete separation, etc., to reduce energy costs, improve the separation method, and improve the process level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

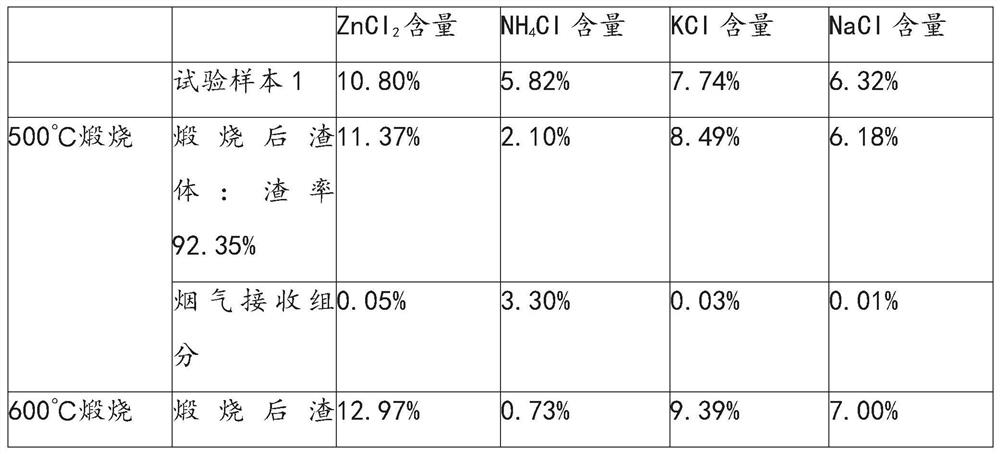

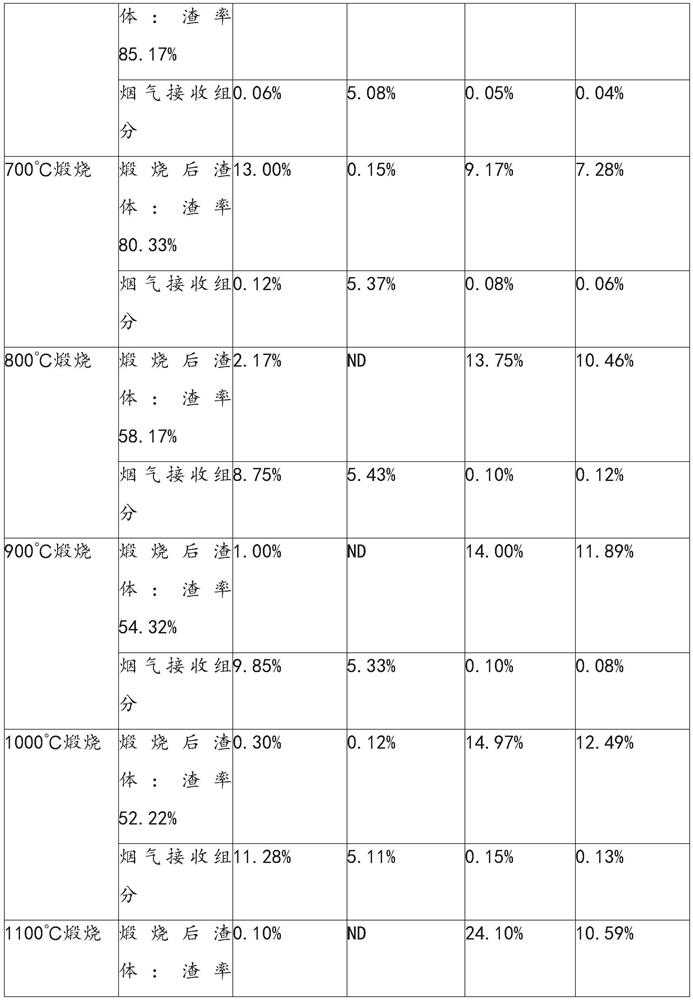

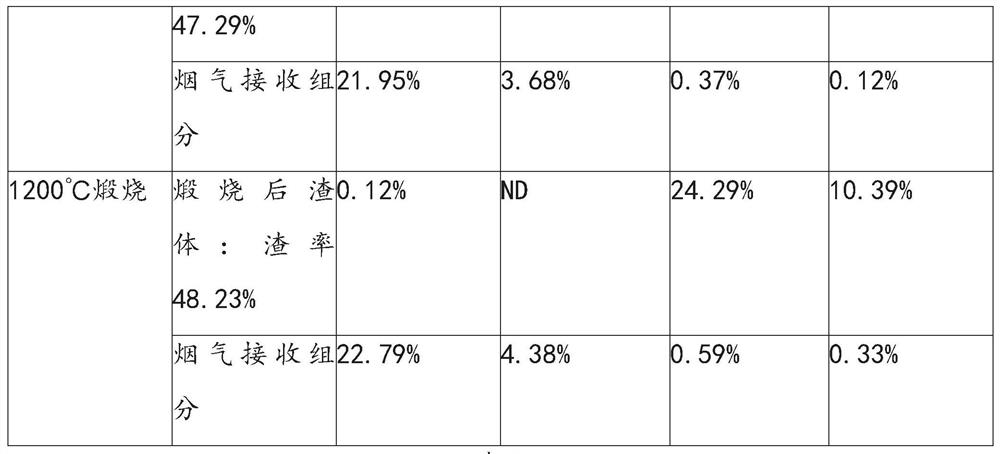

[0044] This example provides a plurality of test samples, all test samples 1, 2 and 3 are respectively taken from different chlorinated blocks produced by de-F and CI of sub-zinc oxide, and each temperature test is that the samples are heated from room temperature to After drying the moisture at 200 °C, continue to heat up to the required temperature and calcinate at a constant temperature for 30 minutes. The slag rate test is completed in a muffle furnace, and the flue gas receiving test is completed in a tubular electric furnace equipped with a flue gas receiving device.

[0045] Among them, the quantitative test of zinc chloride is detected by EDTA titration method, AAS method or icp method;

[0046] The quantitative test of ammonium chloride is detected by NaOH titration;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com