Modified spinel type positive electrode material, preparation method thereof and lithium ion battery positive plate

A lithium-ion battery, spinel-type technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as crystal structure changes, prone to disproportionation reactions, and reduced battery charge-discharge performance, and achieves inhibition of transformation, The effect of reducing the Jahn-Teller effect and suppressing the degradation of the crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

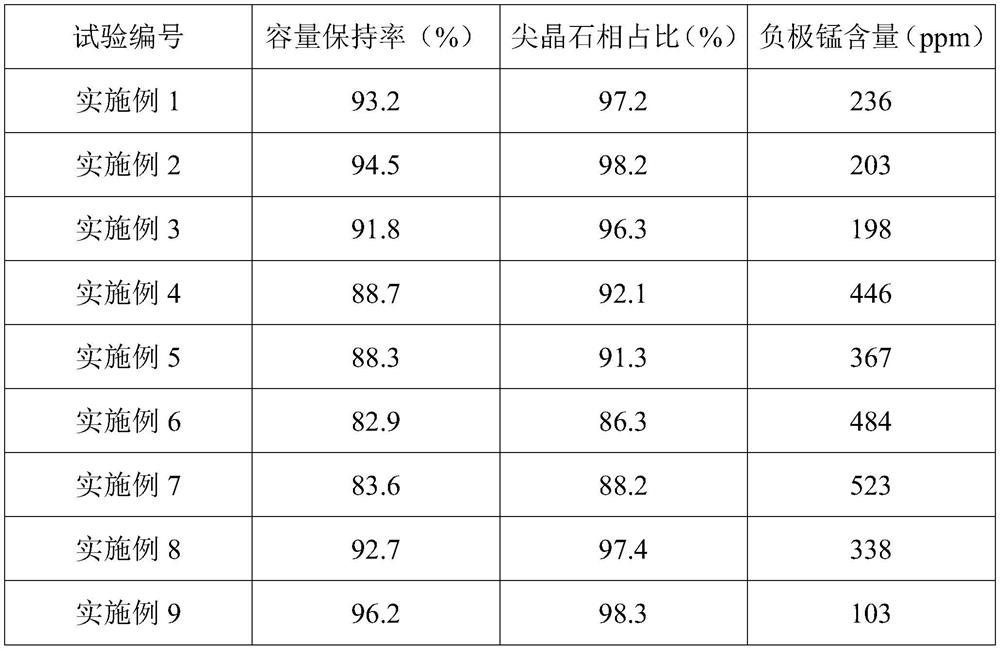

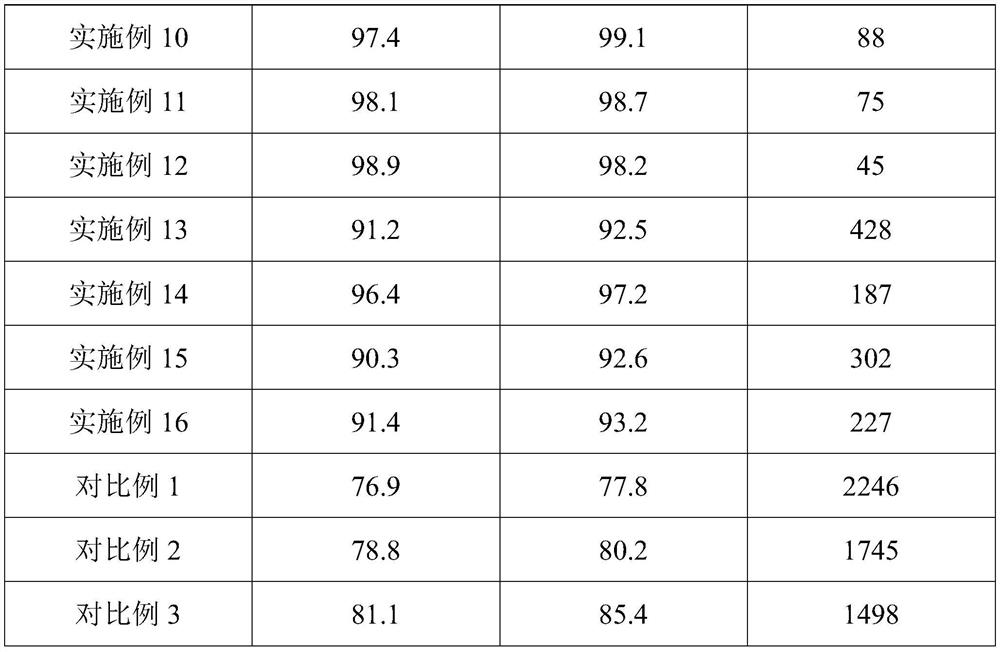

Examples

Embodiment 1

[0038] This embodiment provides a modified spinel-type positive electrode material, in which the modified spinel-type positive electrode material is doped with metal oxide TiO, TiO and lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 The mass ratio of 0.5:99.5; the modified spinel-type positive electrode material is a secondary spherical shape, D 50 The particle size is 30 μm.

[0039] The preparation method of the modified spinel type positive electrode material comprises the following steps:

[0040] Mixed lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 with Ti(CH 3 COO) 2 , get the dopant; with 2.5Nm 3 Nitrogen gas was introduced at a flow rate of / h, and the obtained dopant was sintered for 24 hours at a temperature of 600° C. to obtain the modified spinel-type positive electrode material.

Embodiment 2

[0042] This embodiment provides a modified spinel-type positive electrode material, in which the modified spinel-type positive electrode material is doped with metal oxide MO x , the metal oxide MO x Composed of MgO and NiO with a mass ratio of 8:2, the metal oxide MO x LiNi 0.5 mn 1.5 o 4 The mass ratio of 0.2:99.8, the modified spinel positive electrode material is a secondary spherical shape, D 50 The particle size is 20 μm.

[0043] The preparation method of the modified spinel type positive electrode material comprises the following steps:

[0044] Mixed lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 , MgO and NiO to obtain the dopant; the flow rate is 3Nm 3 / h of helium, and the obtained dopant was sintered at a temperature of 500° C. for 32 hours to obtain the modified spinel positive electrode material.

Embodiment 3

[0046] This embodiment provides a modified spinel-type positive electrode material, in which the modified spinel-type positive electrode material is doped with metal oxide MO x , the metal oxide MO x Composed of BaO and SrO with a mass ratio of 3:7, the metal oxide MO x LiNi 0.5 mn 1.5 o 4 The mass ratio of 0.8:99.2, the modified spinel positive electrode material is a secondary spherical shape, D 50 The particle size is 45 μm.

[0047] The preparation method of the modified spinel type positive electrode material comprises the following steps:

[0048] Mixed lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 , BaO and SrO to obtain dopant; the flow rate is 4Nm 3 / h of argon, and the obtained dopant was sintered at a temperature of 700° C. for 16 hours to obtain the modified spinel positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com