Method for improving high-temperature breakdown performance of polypropylene film of capacitor

A polypropylene film and capacitor technology, used in flat products, household appliances, other household appliances, etc., can solve the problems of capacitor bulging, explosion, and increased conductivity loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

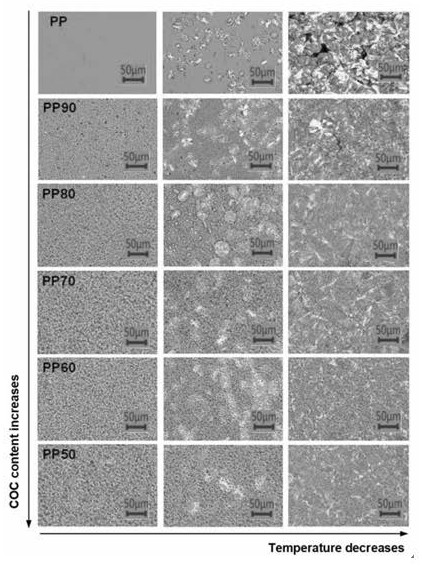

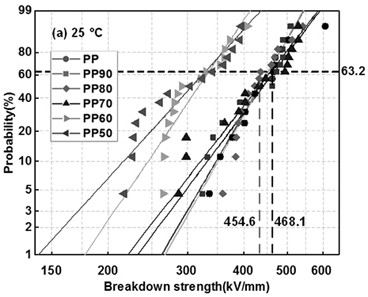

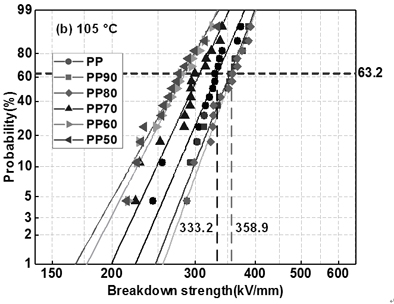

[0033] A method for improving the high-temperature breakdown performance of a capacitor polypropylene film, comprising the following steps:

[0034] (1) Put the cycloolefin copolymer particles with a glass transition temperature of 110°C in an oven to dry at a drying temperature of 70°C and a drying time of 30 minutes to remove the moisture in the material;

[0035] (2) Mix the dried cyclic olefin copolymer and polypropylene on a two-roller machine, the mass fraction of the cyclic olefin copolymer is 10%, the mixing temperature is 190°C, and the mixing time is 10 minutes;

[0036] (3) Put the mixture of polypropylene and cyclic olefin copolymer on a flat vulcanizing machine for hot pressing and setting, the setting time is 5min, the setting temperature is 190°C, and the pressure is 24MPa;

[0037] (4) Keep the pressure at 24MPa, and use a cooling device to cool the temperature from 190°C to 120°C;

[0038] (5) After the cooling is completed, take out the cycloolefin copolymer...

Embodiment 2

[0040] A method for improving the high-temperature breakdown performance of a capacitor polypropylene film, comprising the following steps:

[0041] (1) Put the cycloolefin copolymer particles with a glass transition temperature of 110°C in an oven to dry at a drying temperature of 70°C and a drying time of 30 minutes to remove the moisture in the material;

[0042] (2) Mix the dried cyclic olefin copolymer and polypropylene on a two-roller machine, the mass fraction of the cyclic olefin copolymer is 20%, the mixing temperature is 190°C, and the mixing time is 10 minutes;

[0043] (3) Put the mixture of polypropylene and cyclic olefin copolymer on a flat vulcanizing machine for hot pressing and setting, the setting time is 5min, the setting temperature is 190°C, and the pressure is 24MPa;

[0044] (4) Keep the pressure at 24MPa, and use a cooling device to cool the temperature from 190°C to 120°C;

[0045] (5) After the cooling is completed, take out the cycloolefin copolymer...

Embodiment 3

[0047] A method for improving the high-temperature breakdown performance of a capacitor polypropylene film, comprising the following steps:

[0048] (1) Put the cycloolefin copolymer particles with a glass transition temperature of 110°C in an oven to dry at a drying temperature of 70°C and a drying time of 30 minutes to remove the moisture in the material;

[0049] (2) Mix the dried cyclic olefin copolymer and polypropylene on a two-roller machine, the mass fraction of the cyclic olefin copolymer is 30%, the mixing temperature is 190°C, and the mixing time is 10 minutes;

[0050] (3) Put the mixture of polypropylene and cyclic olefin copolymer on a flat vulcanizing machine for hot pressing and setting, the setting time is 5min, the setting temperature is 190°C, and the pressure is 24MPa;

[0051] (4) Keep the pressure at 24MPa, and use a cooling device to cool the temperature from 190°C to 120°C;

[0052](5) After the cooling is completed, take out the cycloolefin copolymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com