Hypercrosslinked poly-porous resin adsorbent for blood perfusion and preparation method thereof

An ultra-high cross-linked, porous resin technology, applied in chemical instruments and methods, other chemical processes, dialysis systems, etc., can solve problems such as pH reduction, health threats to production operators, environmental pollution, etc., and achieve effective control of specific surface area. , The effect of solving safety and environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

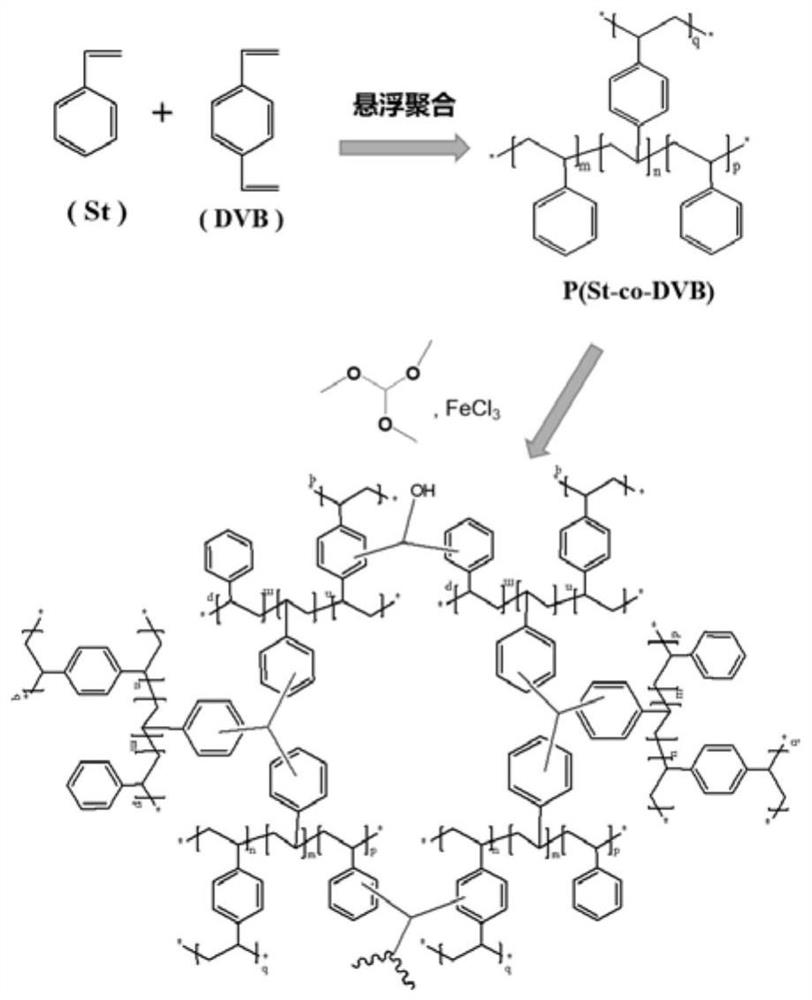

Method used

Image

Examples

Embodiment 1

[0059] Stir 20g 80% divinylbenzene / 20% ethylstyrene, 80g styrene, 150g toluene, 50g methylcyclohexane, 1.5g benzoyl peroxide to form an oil phase; add the oil phase to pre-dissolve evenly The aqueous phase consisting of 800g of deionized water and 15g of gelatin was started, the stirring was started, the mixture was heated in a gradient to 60-80°C, and the temperature was kept constant for 15 hours. The porogen in the polymerized resin is removed and purified to obtain polystyrene-based microspheres.

Embodiment 2

[0061] Stir 50g 80% divinylbenzene / 20% ethylstyrene, 50g styrene, 10g toluene, 190g isooctyl alcohol, and 1.5g benzoyl peroxide to form an oil phase; add the oil phase to the pre-dissolved homogeneous The water phase composed of 500g deionized water and 1g polyvinyl alcohol was started to stir, and the mixture was gradiently heated to 60-90°C, and kept at constant temperature for 9 hours. The porogen in the polymerized resin is removed and purified to obtain polystyrene-based microspheres.

Embodiment 3

[0063] Stir 90g 80% divinylbenzene / 20% ethylstyrene, 10g styrene, 80g toluene, 80g diisobutylmethanol, and 1.5g azobisisobutyronitrile to form an oil phase; add the oil phase to the pre-dissolved A uniform aqueous phase consisting of 1000g deionized water and 5g gelatin was started, and the mixture was heated in a gradient to 60-75°C and kept at a constant temperature for 12 hours. The porogen in the polymerized resin is removed and purified to obtain polystyrene-based microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com