Dry sand wear testing machine and use method thereof

A wear test, dry sand technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of inability to simulate complex scenes, complex equipment structure, single simulation scene, etc., achieve simple structure, simple operation steps, The effect of many control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

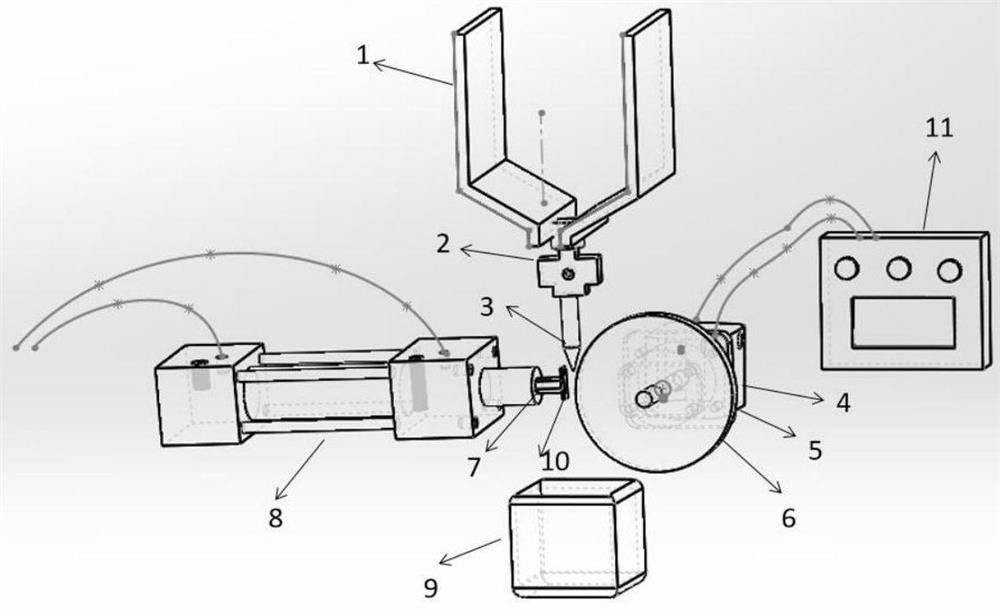

[0028] Such as figure 1 As shown, the dry sand wear testing machine of the present invention includes a sand storage tank 1, a speed controller 2, a sand guide nozzle 3, a servo motor 4, a planetary reducer 5, a rubber wheel 6, a sample holder 7, a control display 11 and a power supply , wherein the bottom of the sand storage tank 1 is connected with the sand guide nozzle 3, the sand guide nozzle 3 is used to guide the dry sand to flow out from the sand storage tank 1; the speed controller 2 is installed on the sand guide nozzle 3, and is used to adjust the dry sand in the sand guide nozzle 3 Flow rate; the rubber wheel 6 and the sample holder 7 are on the same horizontal plane, and are respectively placed on both sides below the sand guide nozzle 3, wherein the sand guide nozzle 3 is at a tangent position to the rubber wheel 6 and the sample holder 7; the rubber wheel 6 and the planetary The reducer 5 and the servo motor 4 are connected in turn, and the planetary reducer 5 an...

Embodiment 2

[0033] The using method of dry sand abrasion testing machine of the present invention comprises the steps:

[0034] (1) The rubber wheel connected to the speed controller reducer can adjust the speed and adjust the load applied by the cylinder to the sample; adjust the sand flow rate, the speed of the rubber wheel and the size of the applied load to simulate the friction under different working conditions , and the resistance heater can be freely loaded and unloaded to heat the sample, simulating the friction and wear at different temperatures;

[0035] (2) The selected quartz sand flows downward from the sand storage tank, and flows out from the sand guide nozzle after the speed is regulated by the speed controller, and the friction experiment is carried out on the sample between the rotating rubber wheel and the clamp that applies the load pressure;

[0036] (3) Finally, the sand flows into the sand collection tank after a series of friction processes, and the collected quar...

Embodiment 3

[0038] The sample is a coating brazed at 1060°C, and its hardness is much greater than that of other basic base materials such as carbon steel and stainless steel. Follow the steps below to simulate the wear of the sample:

[0039] (1) The cylinder load is set to 0.1MPA, the speed of the rubber wheel is 144 rpm, and the running time of the testing machine is 5 hours;

[0040] (2) Fix the above sample on the fixture, and fill the sand storage tank with quartz sand, the quartz sand flows out from the sand storage tank through the sand guide nozzle continuously, and the flowing dry sand continuously rubs against the sample under the drive of the rubber wheel;

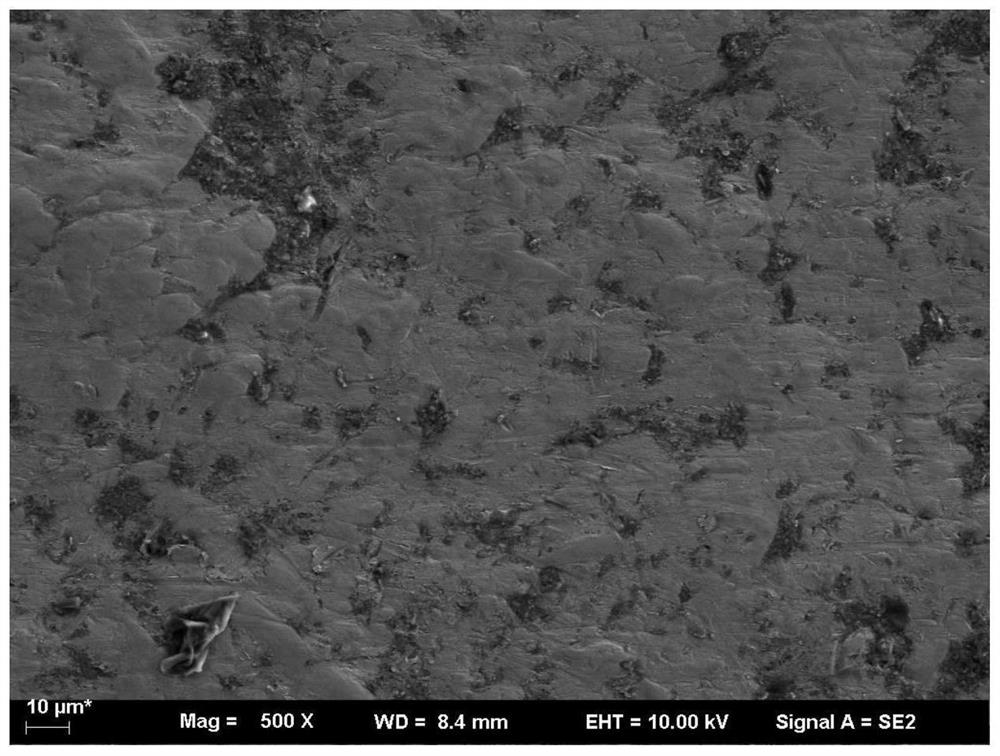

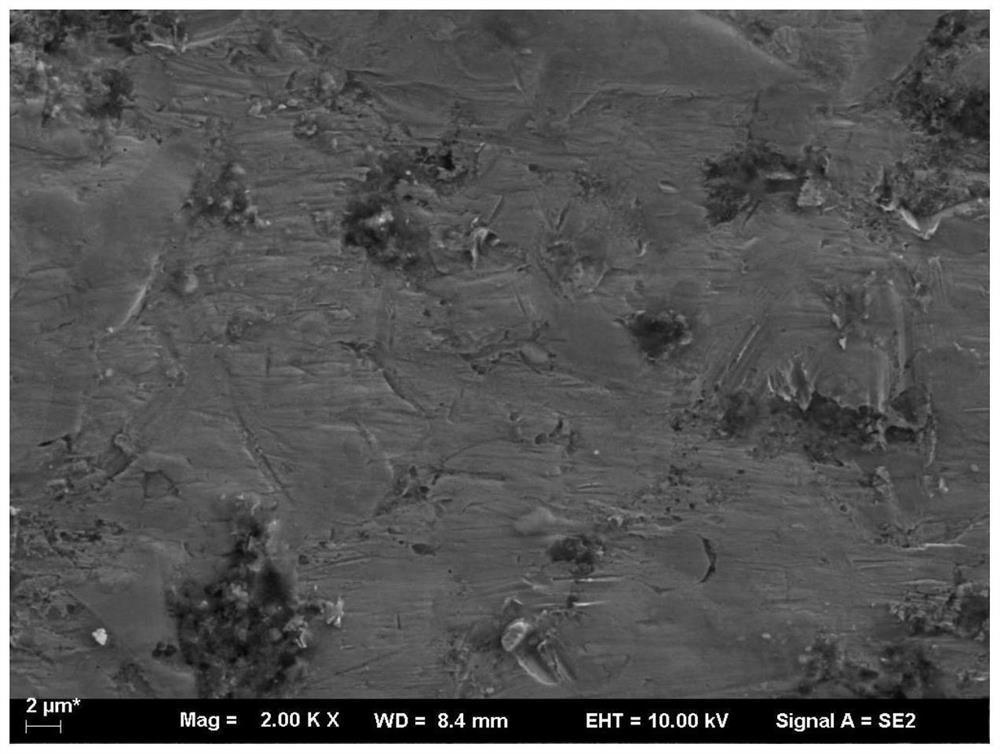

[0041] The wear condition of the sample is judged by calculating the weight loss of the sample before and after wear or the scanning electron microscope image of the sample after wear.

[0042] The mass of 8.9945g before grinding is 8.6695g after 5 hours of wear, and the wear loss rate is 3.61%.

[0043] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com