Method for predicting active silica-alumina ratio of alkali heat activated geopolymer raw material

An active silicon-alumina and geopolymer technology, which is applied in measurement devices, analytical materials, material analysis using wave/particle radiation, etc. Large and other problems, to achieve the effect of eliminating costs and procedures, simple operation process, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for predicting the active silicon-aluminum ratio of the polymer raw material activated by alkali heat, comprising the following steps:

[0039] (1) Use X-ray fluorescence spectrometer to test the chemical composition of shale vanadium extraction tailings, fly ash, and silica fume to obtain the silicon-aluminum mass fraction of the silicon-aluminum raw material. The results are shown in Table 1;

[0040] (2) The mass ratio of the three raw materials is 100:0:4, 90:10:4, 80:20:4, 70:30:4, 60:40:4, 50:50:4 corresponding to 6 groups Mix the raw materials, and calculate the raw material silicon-aluminum molar ratios of the 6 groups of mixed raw materials respectively, which are recorded as M1, M2, M3, M4, M5, and M6, and the results are shown in Table 2;

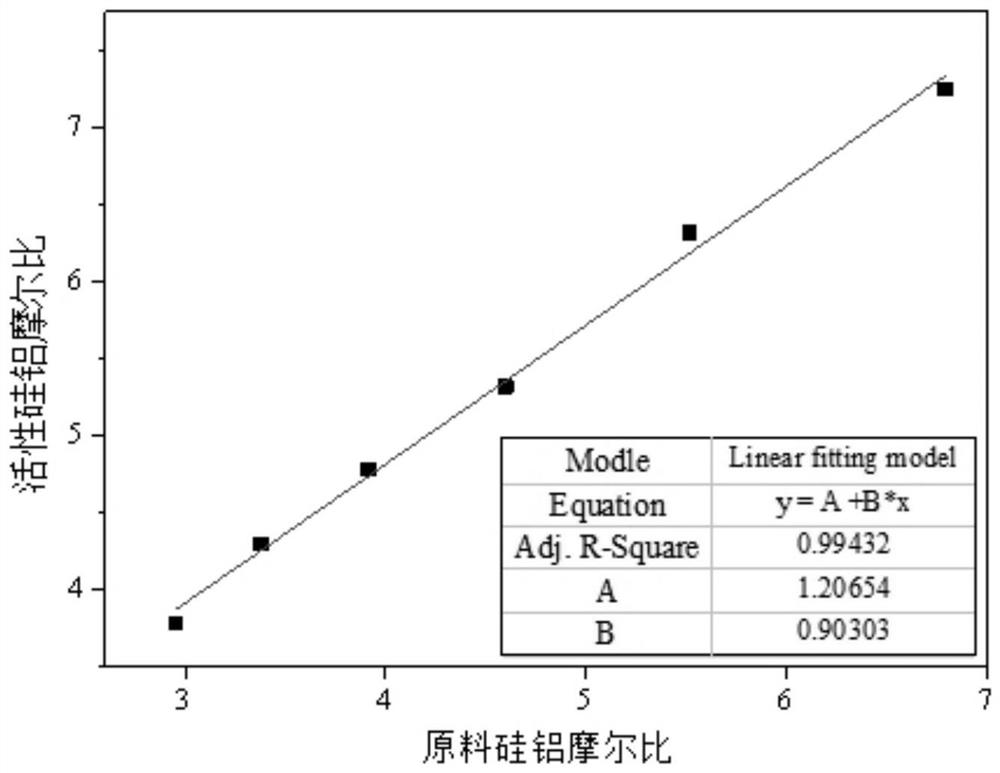

[0041] (3) Mix the above-mentioned 6 groups of mixed raw materials with NaOH accounting for 25% of the mass of each group of mixed raw materials, mix and stir evenly, and perform an alkali heat activation treatmen...

Embodiment 2

[0050] A method for predicting the active silicon-aluminum ratio of the polymer raw material activated by alkali heat, comprising the following steps:

[0051] (1) Use an X-ray fluorescence spectrometer to test the chemical composition of fly ash, granite powder, and sludge to obtain the silicon-aluminum mass fraction of the silicon-aluminum raw material. The results are shown in Table 3;

[0052] (2) The mass ratio of the three raw materials is 80:10:10, 60:20:20, 40:30:30, 20:40:40, 40:50:10, 20:60:20, 20:70 :10, 10:80:10 to obtain the corresponding 8 groups of mixed raw materials, and calculate the raw material silicon aluminum molar ratio of 8 groups of mixed raw materials, recorded as M1, M2, M3, M4, M5, M6, M7, M8, the results are shown in Table 4 ;

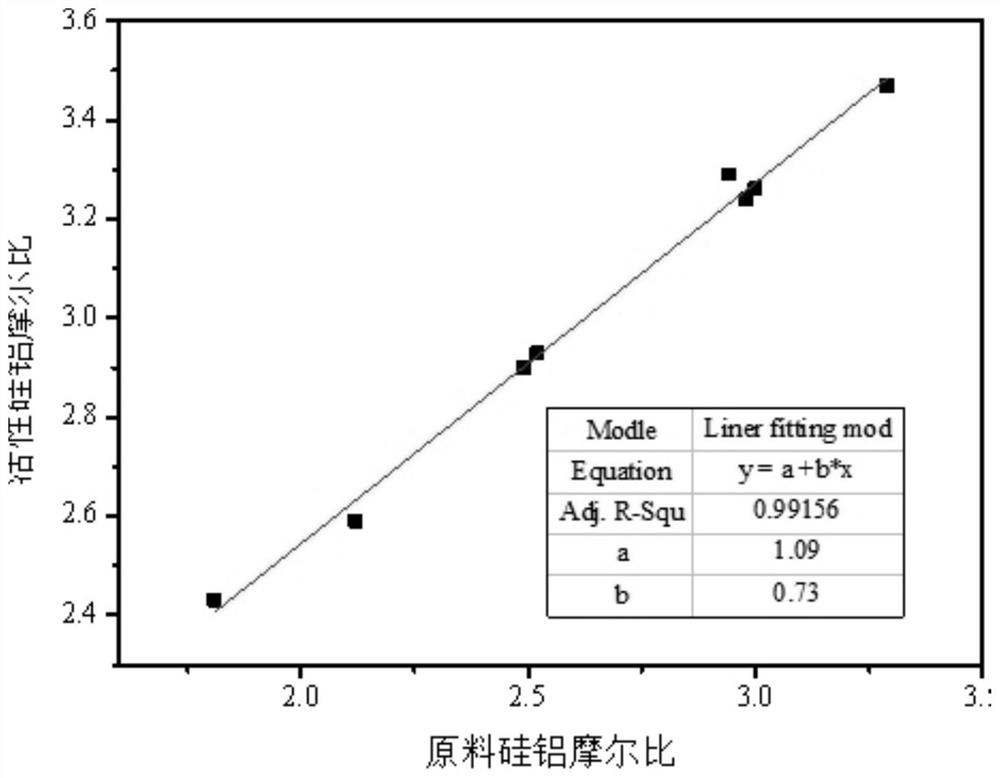

[0053] (3) Mix the above-mentioned 8 groups of mixed raw materials with NaOH accounting for 15% of the mass of each group of mixed raw materials, mix and stir evenly, undergo alkali heat activation treatment at 600 ° C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com