LED epitaxial structure, preparation method thereof and LED chip

A technology of LED chip and epitaxial structure, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the internal quantum efficiency of LED chips and low crystal quality, so as to improve internal quantum efficiency, reduce defect density, and improve crystal growth. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

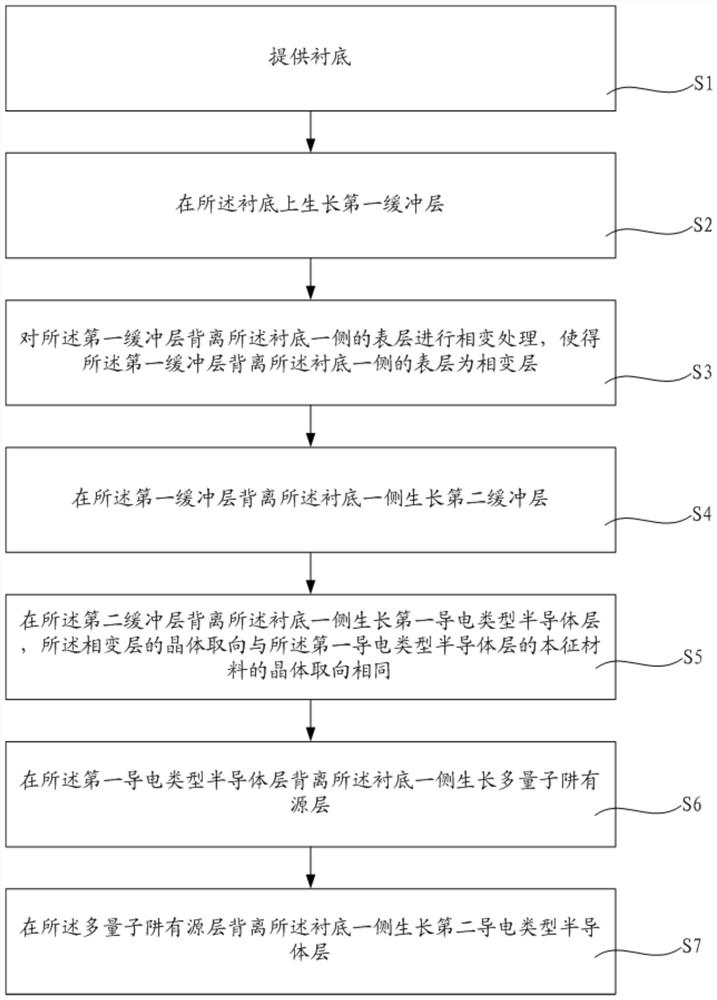

[0044] refer to figure 1 As shown, it is a flow chart of a method for preparing an LED epitaxial structure provided by an embodiment of the present invention, wherein the method for preparing an LED epitaxial structure includes:

[0045] S1. Providing a substrate.

[0046] S2. Growing a first buffer layer on the substrate.

[0047] S3. Perform phase change treatment on the surface layer of the first buffer layer facing away from the substrate, so that the surface layer of the first buffer layer facing away from the substrate is a phase change layer.

[0048] S4. Growing a second buffer layer on a side of the first buffer layer facing away from the substrate.

[0049] S5. Growing a first conductivity type semiconductor layer on a side of the second buffer layer away from the substrate, the crystal orientation of the phase change layer is the same as the crystal orientation of the intrinsic material of the first conductivity type semiconductor layer.

[0050] S6. Growing a mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com