Modified antistatic composite superfine fiber mold cup and preparation method thereof

A microfiber, antistatic technology, applied in clothing, underwear, bras, etc., can solve the problems of no antistatic, can not be discharged in time, can not flow exhaust gas, etc., to achieve the effect of softness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A modified antistatic composite superfine fiber mold cup is composed of natural latex material, bamboo charcoal fiber, rubber cotton and antistatic brushed cloth.

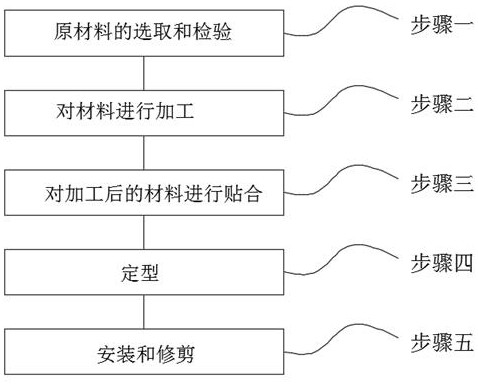

[0028] A method for preparing a modified antistatic composite superfine fiber mold cup, comprising step 1, selection and inspection of raw materials; step 2, processing the materials; step 3, laminating the processed materials; step 4, setting the shape ; Step five, installation and pruning;

[0029] Wherein in the above-mentioned step one, select natural latex material, bamboo charcoal fiber, rubber cotton and antistatic brushed cloth, and check whether the selected material is qualified;

[0030] Among them, in the above-mentioned step two, the staff will make the natural latex material into the latex layer, and the bamboo

[0031] Carbon fiber and rubber cotton are cold pasted to make the inner material layer, and the antistatic brushed fabric is made into the cup pattern layer;

[0032] In the third st...

Embodiment 2

[0036] In step 1, check the basic indicators and appearance quality of the brushed fabric, such as color difference, gram weight, and appearance points. The performance of natural latex materials and rubber cotton is easy to fluctuate, and manual sampling inspection is required. The inspection indicators are gram weight, hardness, and foam body. Density, tensile rate, compression recovery rate and color difference, etc.; different materials need to be set at different temperatures during molding and setting. Generally, the temperature of the upper mold is about 195°C, and the temperature of the lower mold is about 4°C lower than that of the upper mold. The temperature is low, the handle is rough, the overall thickness of the cotton cup is too thick, the volume of the bowl becomes smaller, the shape of the extruded cotton cup is not obvious, and the original sponge state still exists. If the temperature is high, the resulting cotton cup feels too smooth and stiff, without Elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com