Preparation method of degradable magnesium alloy capillary tube for intravascular stent

A vascular stent and magnesium alloy technology are applied in the field of preparation of degradable magnesium alloy capillary materials for vascular stents, which can solve the problems of complicated preparation process of magnesium alloy seamless capillary, and achieve the effects of low processing cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

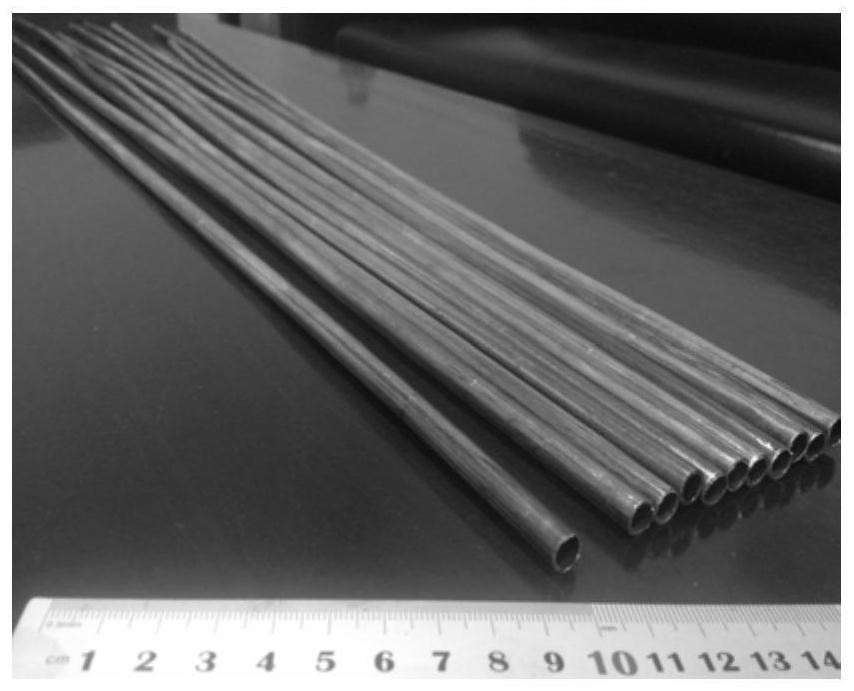

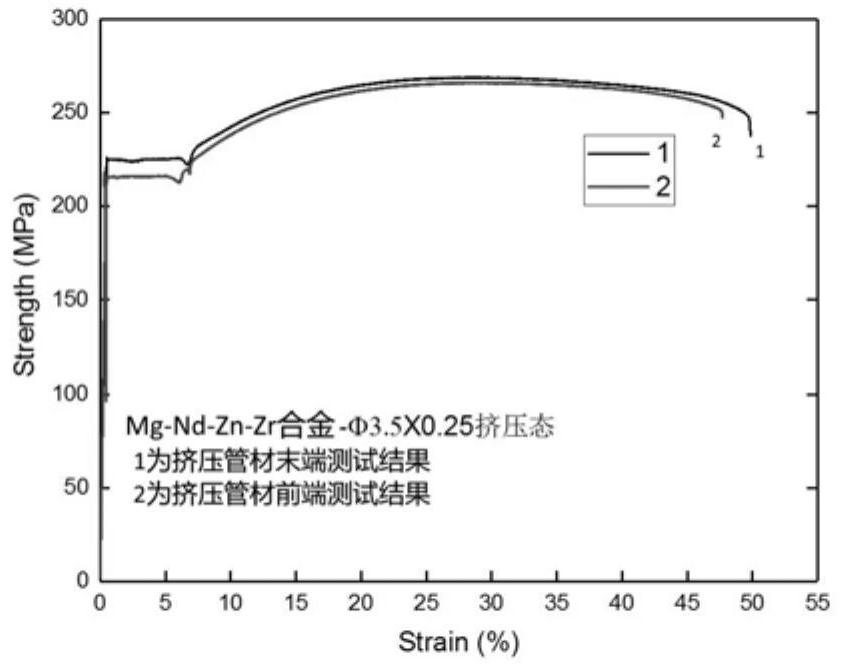

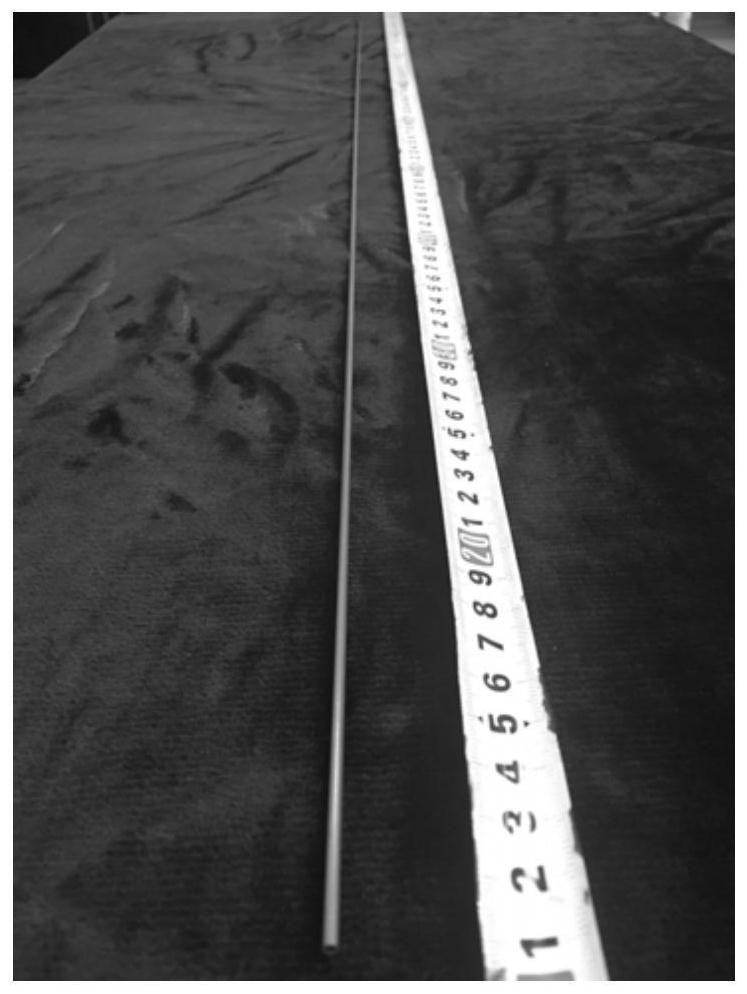

[0033] Embodiment 1: (1) select Mg-2.1Nd-0.2Zn-0.5Zr) (wt.%) alloy material, (2) machining a hot extrusion billet with an outer diameter of 10mm, a height of 25mm, and a center hole of 3mm; (3) At 380°C, hot extrusion is carried out according to the extrusion ratio of 40:1. During hot extrusion, the hot extruded capillary billet is subjected to rapid cooling treatment (compressed air cooling at room temperature); the shape of the extruded tube billet as attached figure 1 As shown, the length is 1000mm, the outer diameter is 3.5mm, and the wall thickness is 0.25mm. The tensile mechanical properties of the tube blank at room temperature are shown in the attached figure 2 (4) 4 passes of drawing at 390°C, the amount of drawing deformation in each pass is controlled at 20%, and the drawn pipe is as attached image 3 The grain size of the tubing is shown in the attached Figure 4 As shown; (5) After testing and drawing, the outer diameter of the pipe is 3mm, the wall thickness i...

Embodiment 2~6

[0035]

[0036] Compared with the prior patent ZL201010204716.5, the present invention can improve the uniformity of wall thickness, dimensional accuracy, and mechanical properties to a certain extent, and the dimensional accuracy can be stably within the range of ±0.01mm. Compared with the previous patent ZL201310327209.4, due to the shorter process flow, the quality stability of the product has been greatly improved, and the yield rate has reached 99%, resulting in a significant improvement in the actual application effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com