Novel tunnel type fixed bed reactor for sewage treatment

A fixed-bed reactor and sewage treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of low biomass mass transfer efficiency and damage to subsequent units Equipment, channel flow and other problems, to achieve the effect of reducing the difficulty of tank transformation, reducing the combination of process units and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

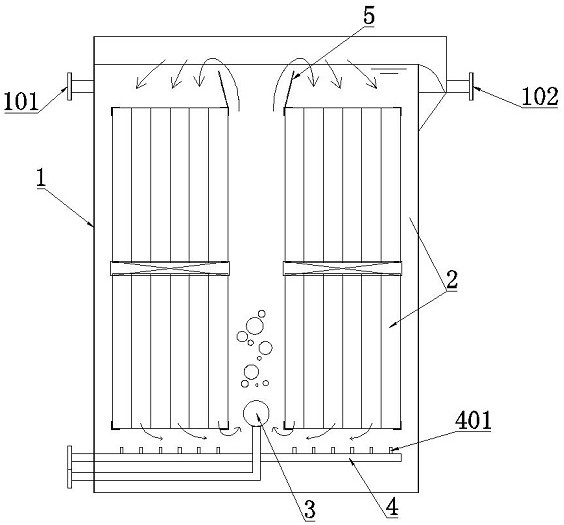

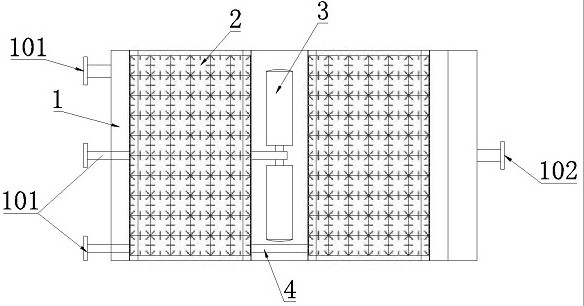

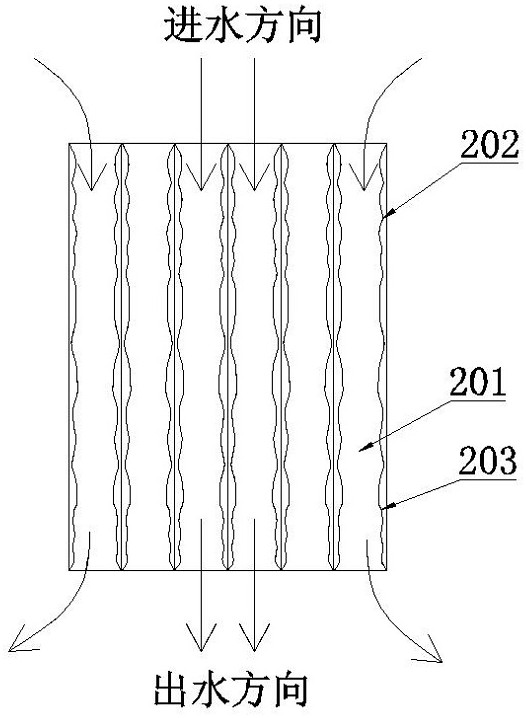

[0036] Such as Figure 1-6 As shown, this embodiment provides a novel tunnel-type fixed-bed reactor for sewage treatment. The fixed-bed reactor 1 is provided with a water inlet 101 and a water outlet 102. Several packing assemblies are fixedly installed, and the packing assemblies are submerged in the sewage; the packing assemblies include several biological packing 2 arranged in parallel, and the biological packing 2 is provided with a channel 201 with a length of at least 20 cm, and the water inlet section on the inner wall of the channel 201 grows well. Oxygen biofilm 202, anoxic biofilm 203 grows in the water outlet section, wherein other biofilms may also grow in the water inlet section and the water outlet section, such as facultative biofilm, etc., but the aerobic biofilm 202 and anoxic biofilm respectively 203-based; the packing assembly is formed by several biological fillers 2 connected in parallel, or several biological fillers 2 are connected in series to form 2 gr...

Embodiment 2

[0043] On the basis of Embodiment 1, an aeration scour pipe 4 is installed below the packing assembly, and the aeration scour pipe 4 is provided with holes or several nozzles 401 are installed. When the aging biofilm attached to the inner wall of the biological filler 2 can no longer be removed by normal water flow, the bottom is intermittently aerated through the aeration flushing tube 4 below the filler assembly, and the air bubbles rise upward to generate shear force to assist the film removal. The biofiller 2 has a tunnel-like through-type structure that penetrates up and down, and the removed biofilm can be smoothly discharged from the channel 201, avoiding the occurrence of clogging, thereby ensuring efficient operation in the later stage.

Embodiment 3

[0045] On the basis of Example 2, a baffle 5 is installed on the top of the packing assembly, the baffle 5 is hinged on the top of the packing assembly and a fixed connector is arranged between the baffle 5 and the packing assembly, and the baffle is adjusted 5. Fix the baffle plate 5 on the top of the packing assembly with a fixed connecting piece after the inclination angle on the packing assembly, wherein the fixed connecting piece can be a connecting plate connected by bolts to the baffle plate 5 and the packing assembly.

[0046] At the same time, the bottom, middle or upper part of the baffle 5 can be hinged on the top of the packing assembly as required, so that not only the angle at which the air-lifting water enters the inside of the packing assembly can be adjusted by adjusting the inclination angle of the baffle 5, but also can be adjusted by adjusting the baffle. 5 Expose the length of the top of the packing assembly to adjust the amount of air-lifted water entering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com