Circulating treatment system for high-ammonia-nitrogen wastewater

A cycle treatment, high ammonia nitrogen technology, applied in the direction of water/sewage treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of long treatment process, high treatment cost, low treatment efficiency, etc., to achieve increased The effect of large contact area, increased efficiency, and rapid purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will be further described below with reference to the specific embodiments:

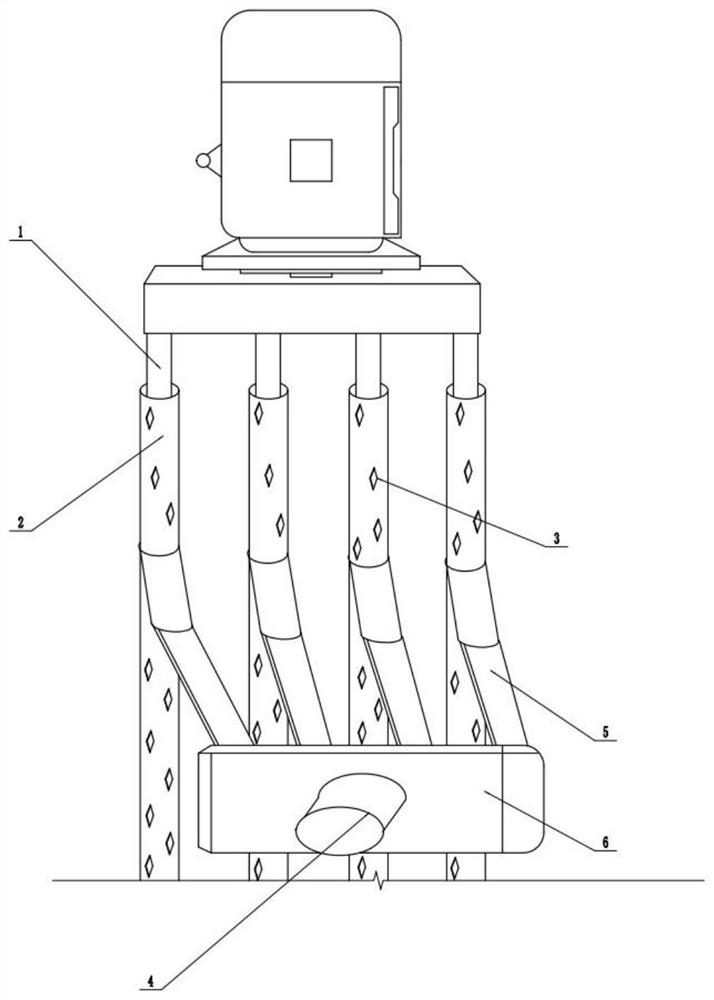

[0025] Reference numerals in the accompanying drawings include: rotating shafts 1, exchange tube 2, pair of flow holes 3, into the liquid pump 4, into the inlet manifold 5, and the liquid pipe 6.

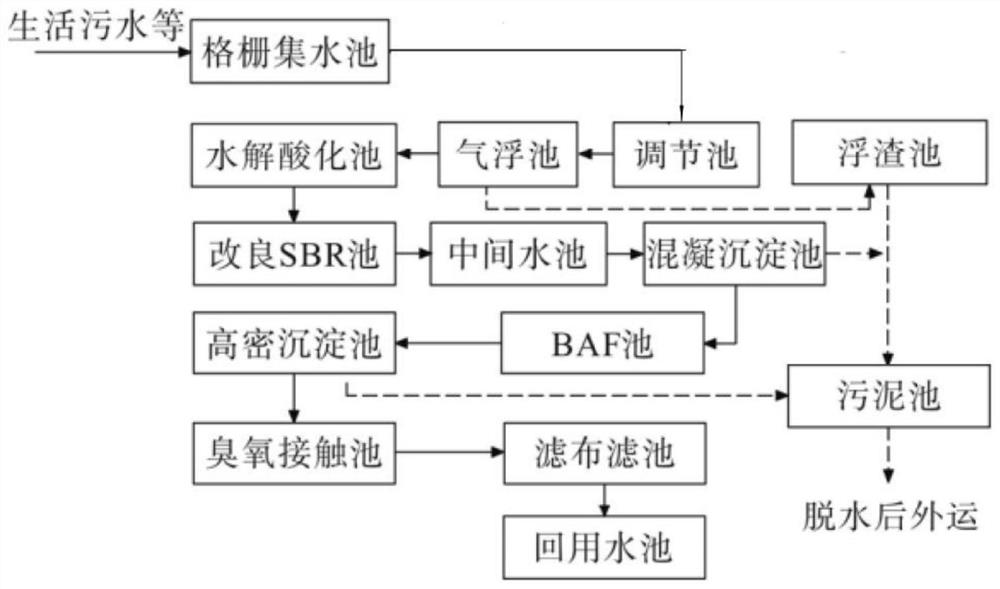

[0026] Embodiments are basically figure 1 As shown: a circulating treatment system of a high-amamine nitrogen wastewater includes a gas floating pool, a pretreatment system, a rear processing system, a gas floating pool connection into a pretreatment system, and the pre-processing system includes a grid set pool, a pre-processing system connected to the adjustment pool In the rear processing system, the adjustment pool is connected to the rear processing system, including hydrolyzed acidified tanks, modified SBR pool, intermediate pool, condensate pond, BAF pool, high-density sedimentation tank, ozone contact pond, filter cloth filter And reuse in the pool, where the concrete sedimentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com