Preparation method of core-shell structure piezoelectric material and piezoelectric nano generator

A piezoelectric material and core-shell structure technology, applied in the field of materials, can solve the problems of ceramic filling phase aggregation, complex material synthesis process, service life period, etc., to achieve the effect of improving piezoelectric output and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

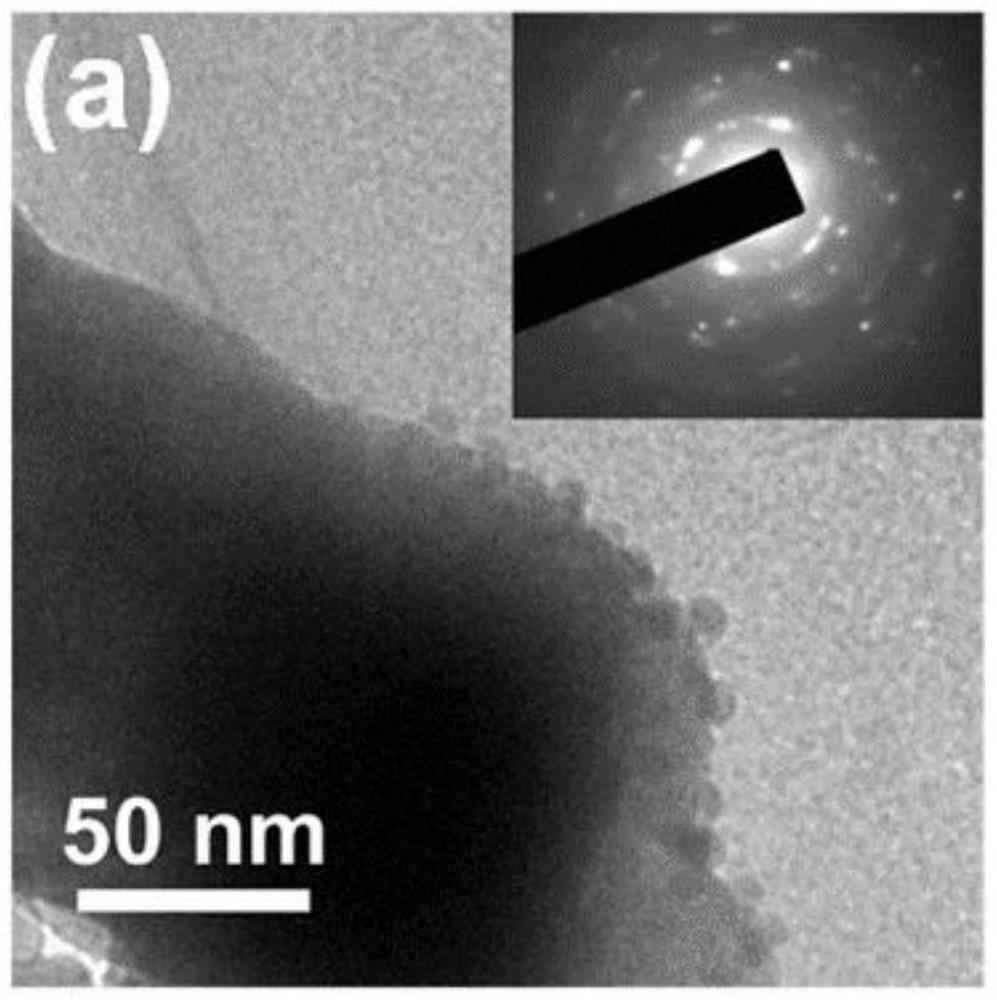

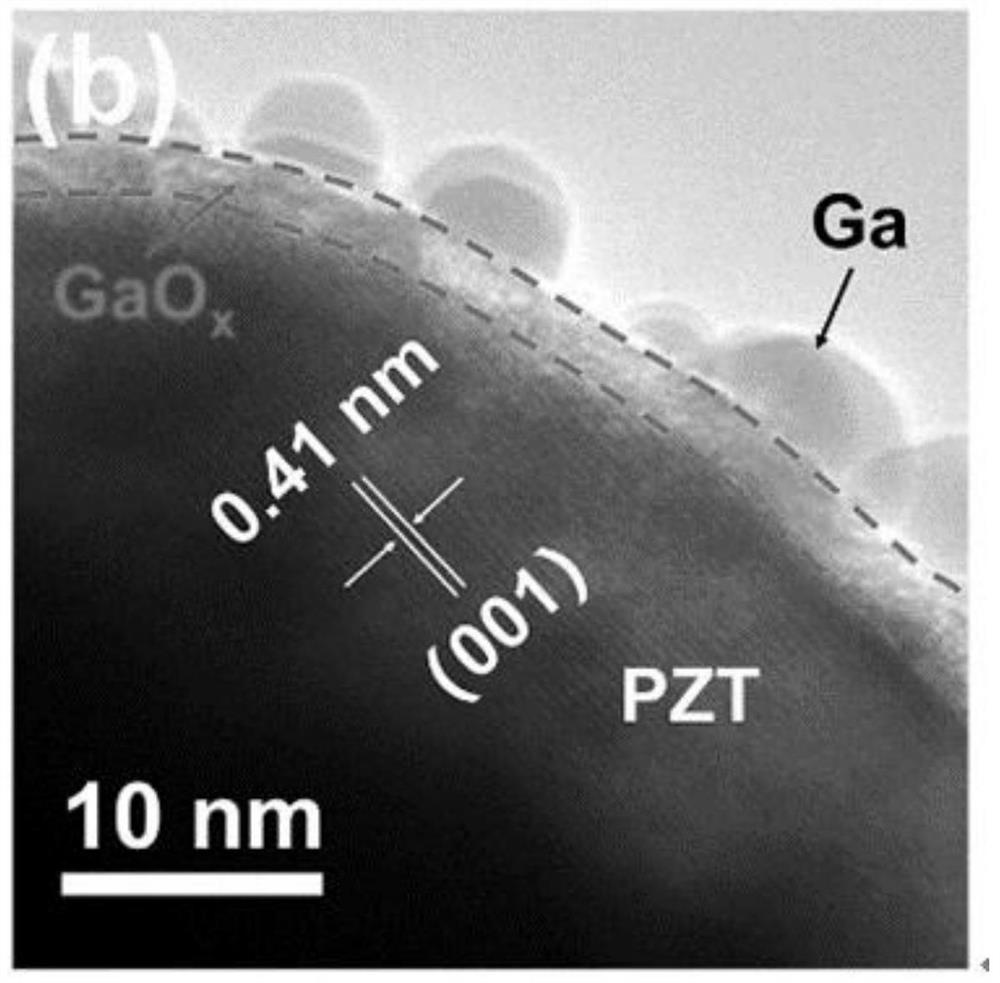

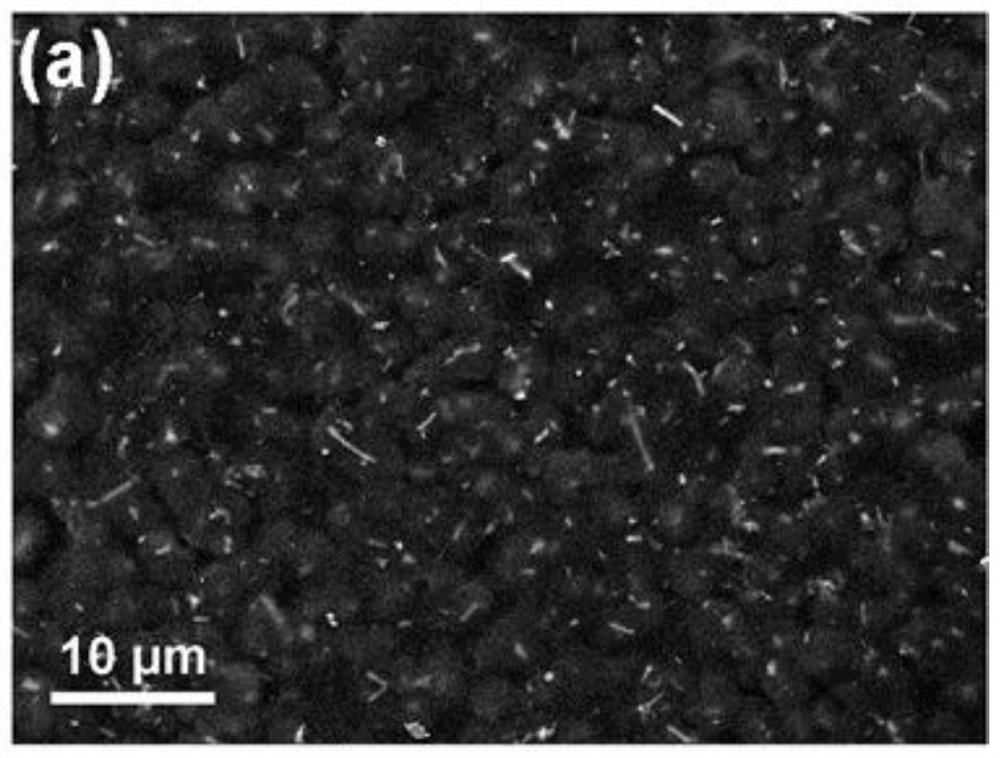

Image

Examples

Embodiment 1

[0067] (1) Take 5.005g of tetrabutyl titanate, 13.88g of acetic acid, 4.4g of acetylacetone, 10.57g of ethanol, 8.24g of basic lead acetate and 7.8016g of zirconium acetylacetonate into a 50mL Erlenmeyer flask, stir for 24h, and prepare into a PZT electrospinning precursor.

[0068] (2) Use a 5mL needle to take 2mL of the precursor solution obtained in step (2) and put it into the electrospinning equipment for electrospinning. Adjust the electrospinning parameters: the receiving plate distance is 20cm, the voltage is 21kV, and the advancing speed is 1mL / h.

[0069] (3) Put the film obtained in step (2) into a crucible, and perform annealing treatment in an annealing furnace. During the annealing process, the temperature was raised to 400°C at a heating rate of 5°C / min, kept for 30 minutes, then raised to 750°C, kept for 2 hours and naturally cooled to room temperature.

[0070] (4) Add the result of step (3) into a mortar and a small amount of alcohol, and grind until the alc...

Embodiment 2

[0082] (1) Take 5.005g of tetrabutyl titanate, 13.88g of acetic acid, 4.4g of acetylacetone, 10.57g of ethanol, 8.24g of basic lead acetate and 7.8016g of zirconium acetylacetonate into a 50mL Erlenmeyer flask, stir for 24h, and prepare into a PZT electrospinning precursor.

[0083] (2) Use a 5mL needle to take 2mL of the precursor solution obtained in step (2) and put it into the electrospinning equipment for electrospinning. Adjust the electrospinning parameters: the receiving plate distance is 20cm, the voltage is 21kV, and the advancing speed is 1mL / h.

[0084] (3) Put the film obtained in step (2) into a crucible, and perform annealing treatment in an annealing furnace. During the annealing process, the temperature was raised to 400°C at a heating rate of 5°C / min, kept for 30 minutes, then raised to 750°C, kept for 2 hours and naturally cooled to room temperature.

[0085] (4) Add the result of step (3) into a mortar and a small amount of alcohol, and grind until the alcoh...

Embodiment 3

[0094] (1) Take 5.005g of tetrabutyl titanate, 13.88g of acetic acid, 4.4g of acetylacetone, 10.57g of ethanol, 8.24g of basic lead acetate and 7.8016g of zirconium acetylacetonate into a 50mL Erlenmeyer flask, stir for 24h, and prepare into a PZT electrospinning precursor.

[0095] (2) Use a 5mL needle to take 2mL of the precursor solution obtained in step (2) and put it into the electrospinning equipment for electrospinning. Adjust the electrospinning parameters: the receiving plate distance is 20cm, the voltage is 21kV, and the advancing speed is 1mL / h.

[0096] (3) Put the film obtained in step (2) into a crucible, and perform annealing treatment in an annealing furnace. During the annealing process, the temperature was raised to 400°C at a heating rate of 5°C / min, kept for 30 minutes, then raised to 750°C, kept for 2 hours and naturally cooled to room temperature.

[0097] (4) Add the result of step (3) into a mortar and a small amount of alcohol, and grind until the alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com