Preparation method of synergistically doped modified polyvinylidene fluoride piezoelectric nano-generator

A polyvinylidene fluoride piezoelectric and nanogenerator technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the piezoelectric output of PVDF nanofiber film Problems such as low performance, to achieve the effect of improving output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

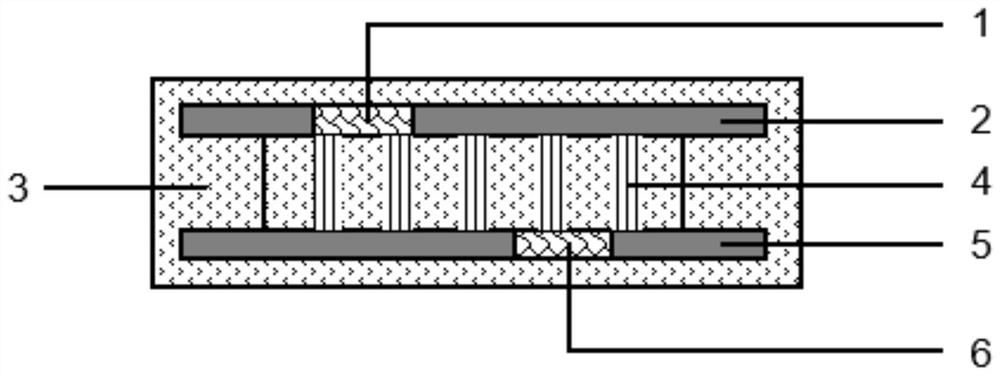

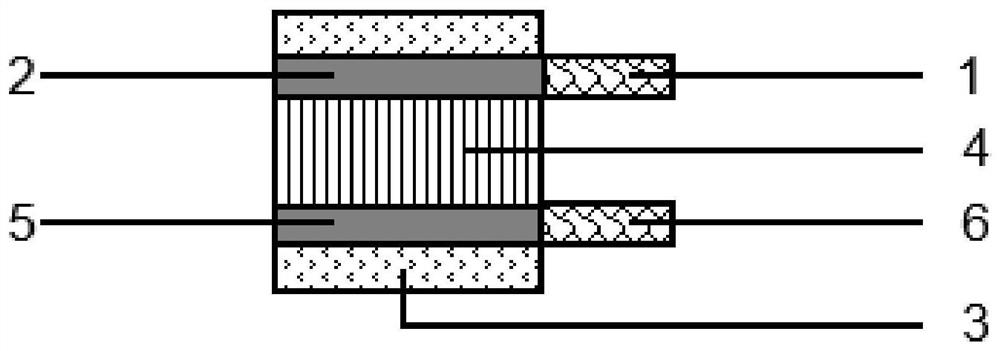

[0048]Add PVDF with a mass fraction of 12wt% into a solvent with a DMAc:acetone ratio of 70:30, and stir until the solution is transparent. Then add 1wt% of vitamin B2, 6wt% of dopamine and 0.1wt% of ZnO, and keep stirring for 120 minutes to fully dissolve vitamin B2 into the PVDF solution to obtain a spinning solution. The above-mentioned spinning solution is subjected to electrospinning, and the parameters of the electrospinning process are: the spinning temperature is 20° C., the relative humidity is 40%, the perfusion speed is 0.5 mL / h, the spinning distance is 10 cm, and the spinning voltage is 15 kV. Silk time is 2h. The prepared nanofiber membrane was dried for 50 minutes to make the solvent evaporate as much as possible. Then add PDMS and curing agent in a petri dish of appropriate size to encapsulate the nanofibrous membrane in PDMS. The prepared nanofiber packaging film was cut into strips with a width of 0.5 mm perpendicular to the nanofiber arrangement direction,...

Embodiment 2

[0050] Add PVDF with a mass fraction of 14wt% into the solution with a DMAc:acetone ratio of 60:40, and stir until the solution is transparent. Then add 5wt% of vitamin B2, 6wt% of dopamine and 1wt% of CNTs, and keep stirring for 120min to fully dissolve vitamin B2 into the PVDF solution to obtain a spinning solution. The above-mentioned spinning liquid is subjected to electrospinning, and the parameters of the electrospinning process are: the spinning temperature is 25°C, the relative humidity is 45%, the perfusion speed is 1.0mL / h, the spinning distance is 15cm, the spinning voltage is 20kV, and the spinning Silk time is 3h. The prepared nanofiber membrane was dried for 40 minutes to make the solvent evaporate as much as possible. Then add PDMS and curing agent in a petri dish of appropriate size to encapsulate the nanofibrous membrane in PDMS. The prepared nanofiber packaging film was cut into strips with a width of 0.6 mm perpendicular to the nanofiber arrangement direct...

Embodiment 3

[0052] Add PVDF with a mass fraction of 16wt% into the solution with a ratio of DMAc:acetone of 50:50, and stir until the solution is transparent. Then add 9wt% sodium niobate particles, 6wt% dopamine and 5wt% BaTiO 3 , and continued to stir for 300 minutes to fully dissolve the sodium niobate particles into the PVDF solution to obtain a spinning solution. The above-mentioned spinning liquid is subjected to electrospinning, and the parameters of the electrospinning process are: the spinning temperature is 30°C, the relative humidity is 50%, the perfusion speed is 1.5mL / h, the spinning distance is 20cm, and the spinning voltage is 25kV. Silk time is 4h. The prepared nanofiber membrane was dried for 30 minutes to make the solvent evaporate as much as possible. Then add PDMS and curing agent in a petri dish of appropriate size to encapsulate the nanofibrous membrane in PDMS. The prepared nanofiber packaging film was cut into strips with a width of 0.7 mm perpendicular to the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com