Biomedical multilayer metal-based composite substrate with force-electricity and magnetic-electricity response characteristics and preparation method of biomedical multilayer metal-based composite substrate

A multi-layer metal and composite substrate technology, which is applied in the field of biomedicine to achieve the effects of improving force-electricity and magneto-electricity double-response characteristics, increasing the content of beta phase and magnetic phase, and enhancing piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1). First, add 5% CFO particles by mass to N,N-dimethylformamide (DMF) solvent, and ultrasonically disperse them in an ultrasonic cleaner;

[0029] (2). Add P(VDF-TrFE) solid powder to DMF neutralized CFO particle solution with a mass fraction of 5%, stir under ultrasonic until the powder is completely dissolved, and obtain P(VDF-TrFE) solution and P(VDF-TrFE) ) / CFO solution;

[0030] (3). P(VDF-TrFE) or P(VDF-TrFE) / CFO particle solution film was prepared by casting method, and placed in an oven at 37℃ for 24h to form 40μm P(VDF-TrFE) or P(VDF-TrFE) ) / CFO film;

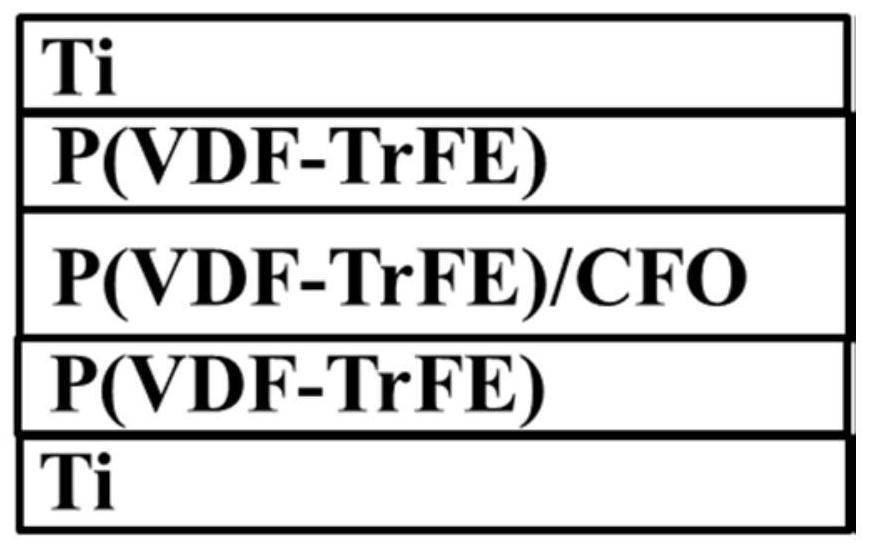

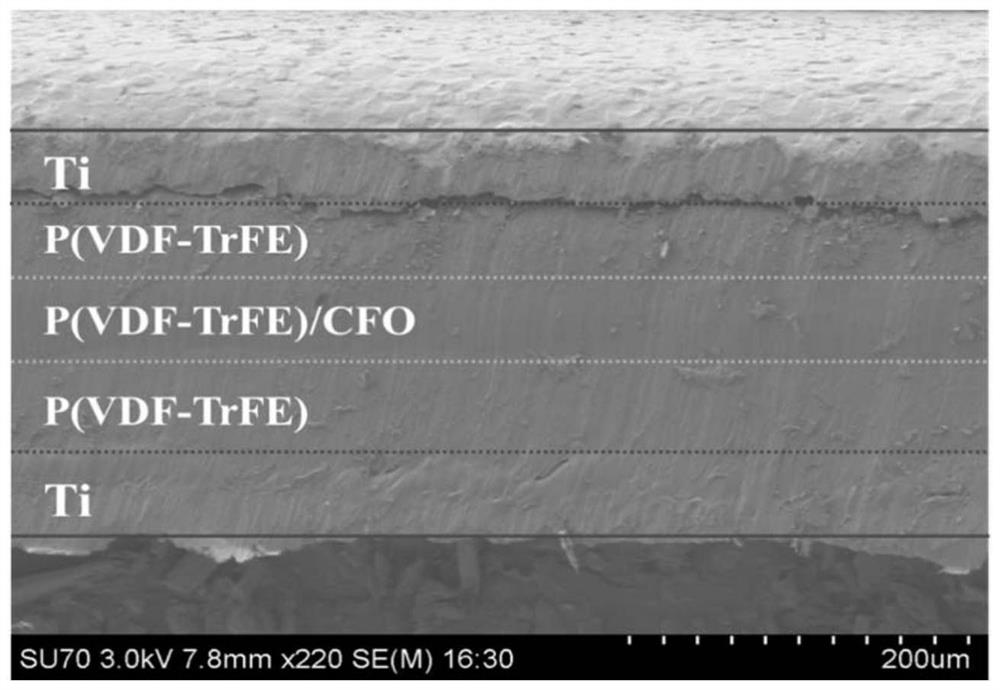

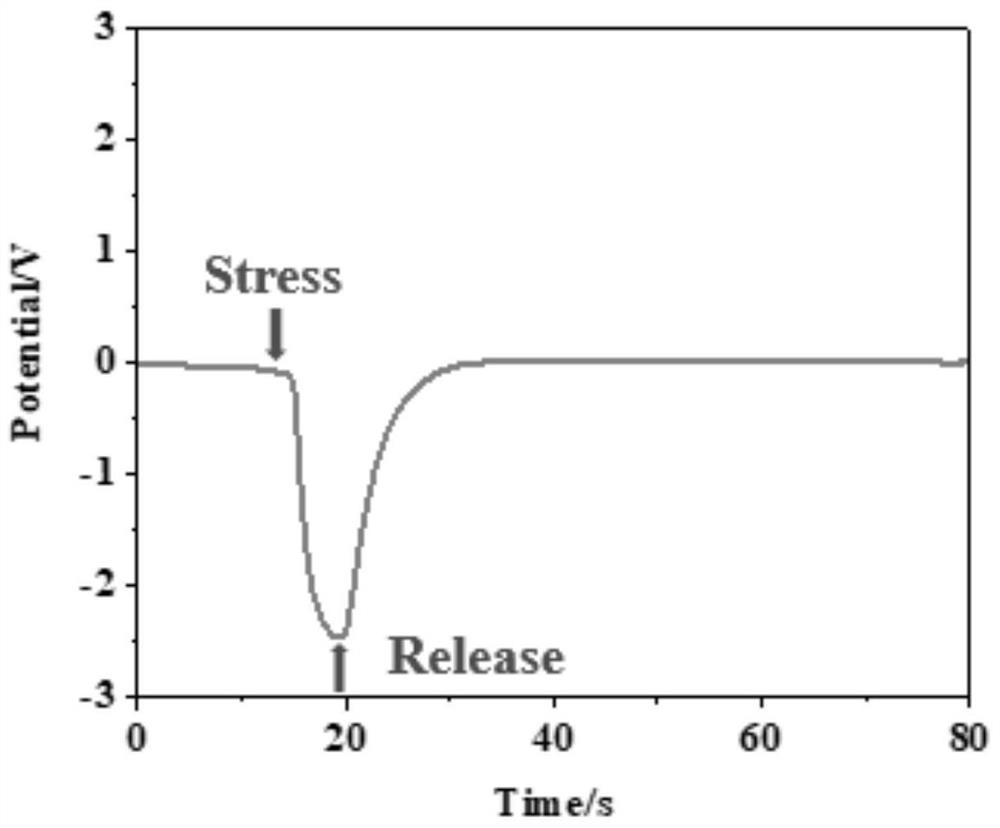

[0031] (4). The metal surface was polished with 400-grit sandpaper, and then treated with oxalic acid for 1 h to obtain a surface roughness of 1.1 μm, and the upper and lower layers of titanium metal with a thickness of 25 μm and the middle 2 layers of P (VDF-TrFE) film and P ( VDF-TrFE) / CFO thin film composed of a multi-layer metal matrix composite substrate with a total thickness of 130 μm, which was hot-p...

Embodiment 2

[0034] (1). First, add 10% Terfenol-D particles by mass to N,N-dimethylformamide (DMF) solvent, and ultrasonically disperse them in an ultrasonic cleaner;

[0035](2). Add the P(VDF-TrFE) solid powder to the DMF neutralized Terfenol-D particle solution with a mass fraction of 10%, stir under ultrasonic until the powder is completely dissolved, and obtain the P(VDF-TrFE) solution and P(VDF) -TrFE) / Terfenol-D solution;

[0036] (3). P(VDF-TrFE) or P(VDF-TrFE) / Terfenol-D film was prepared by casting method, and placed in a 37℃ oven for 24h to form 45μm P(VDF-TrFE) or P(VDF-TrFE) ) / Terfenol-D film;

[0037] (4). The metal surface was polished with 800-grit sandpaper, and then treated with hydrochloric acid for 1.5 hours to obtain a surface roughness of 2.2 μm, and the upper and lower layers of zinc metal with a thickness of 40 μm and the middle 3 layers of P (VDF-TrFE) film and P (VDF-TrFE) / Terfenol-D thin film composed of a multi-layer metal matrix composite substrate with a to...

Embodiment 3

[0040] (1). First, 15% Ni-Co alloy particles were added to N,N-dimethylformamide (DMF) solvent, and ultrasonically dispersed in an ultrasonic cleaner;

[0041] (2). P(VDF-TrFE) solid powder was added to DMF neutralized Ni-Co alloy particle solution with a mass fraction of 15%, and stirred under ultrasonic until the powder was completely dissolved to obtain P(VDF-TrFE) solution and P( VDF-TrFE) / Ni-Co alloy solution;

[0042] (3). P(VDF-TrFE) and P(VDF-TrFE) / Ni-Co thin films were prepared by casting method and placed in an oven at 40℃ for 28h to form 50μm P(VDF-TrFE)P(VDF-TrFE) / Ni-Co alloy film;

[0043] (4). The metal surface was polished with 1500-grit sandpaper, and then treated with sulfuric acid for 2 hours to obtain a surface roughness of 2.9 μm, and the upper and lower layers of tantalum metal with a thickness of 50 μm and the middle 4 layers of P (VDF-TrFE) film and P ( VDF-TrFE) / Ni-Co alloy thin film composed of a multi-layer metal matrix composite substrate with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com