Preparation method of low-voltage electrode foil with good bending fatigue strength

A bending fatigue strength, low-voltage electrode technology, applied in the direction of circuits, capacitors, electrical components, etc., can solve the problem of bending fatigue strength decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

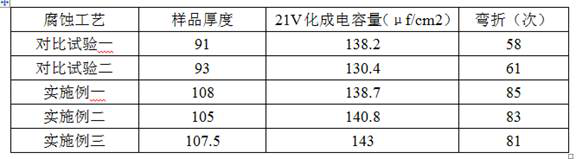

Examples

Embodiment 1

[0033] S1. Immerse the first aluminum foil, the second aluminum foil and the third aluminum foil with a purity of 99.98% and a thickness of 100 μm in a 0.5wt% sodium hydroxide solution. Conditions: temperature 50°C, time 60s;

[0034] S2. Immerse the first aluminum foil obtained in step S1 in 0.25wt% phosphoric acid solution, apply a high-frequency pulse current to perform pre-electrolysis, and the action conditions are: temperature 40°C, time 40s, frequency 14KHz;

[0035] S3. Place the first aluminum foil obtained in step S2 in a mixed solution of 9.0wt% hydrochloric acid, 1.0wt% sulfuric acid, and 1.0wt% oxalic acid for the first electrolytic corrosion, the action conditions: temperature 50 ° C, current is a sine wave Alternating current, current density 0.9A / cm², frequency 45Hz, time 90s; then place it in a mixed solution of 8.0wt% hydrochloric acid, 0.9wt% sulfuric acid, 1.0wt% oxalic acid for the second electrolytic corrosion, working condition: temperature 50 ℃, the cur...

Embodiment 2

[0045] S1. Immerse the first aluminum foil with a purity of 99.98% and a thickness of 100 μm, the second aluminum foil and the third aluminum foil with a purity of 99.98% and a thickness of 10 μm in a 0.5wt% sodium hydroxide solution. Conditions: temperature 50°C, time 60s ;

[0046] S2. Immerse the first aluminum foil, the second aluminum foil and the third aluminum foil obtained in step S1 in a 0.25wt% phosphoric acid solution, and apply a high-frequency pulse current to perform pre-electrolysis. The action conditions are: temperature 40°C, time 40s, Frequency 14KHz;

[0047] S3. Place the first aluminum foil, the second aluminum foil, and the third aluminum foil obtained in step S2 in a mixed solution of 9.0wt% hydrochloric acid, 1.0wt% sulfuric acid, and 1.0wt% oxalic acid for the first electrolytic corrosion. : The temperature is 50°C, the current is a sine wave alternating current, the current density is 0.9A / cm², the frequency is 45Hz, and the time is 90s; then it is p...

Embodiment 3

[0057] S1. Immerse the first aluminum foil with a purity of 99.98% and a thickness of 100 μm, the second aluminum foil and the third aluminum foil with a purity of 99.98% and a thickness of 10 μm in a 0.5wt% sodium hydroxide solution. Conditions: temperature 50°C, time 60s ;

[0058] S2. Immerse the first aluminum foil, the second aluminum foil and the third aluminum foil obtained in step S1 in a 0.25wt% phosphoric acid solution, and apply a high-frequency pulse current to perform pre-electrolysis. The action conditions are: temperature 40°C, time 40s, Frequency 14KHz;

[0059] S3. Place the first aluminum foil, the second aluminum foil, and the third aluminum foil obtained in step S2 in a mixed solution of 9.0wt% hydrochloric acid, 1.0wt% sulfuric acid, and 1.0wt% oxalic acid for the first electrolytic corrosion. : The temperature is 50°C, the current is a sine wave alternating current, the current density is 0.9A / cm², the frequency is 45Hz, and the time is 90s; then it is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com