Rubber mixing and dissolving system and process in polystyrene production

A polystyrene, mixing and dissolving technology, applied in the rubber mixing and dissolving system and process field, can solve the problems of reducing polystyrene production efficiency, increasing the burden of rubber mixing equipment, reducing styrene self-polymerization reaction, etc., to improve service life, The effect of reducing the load and reducing the stirring resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

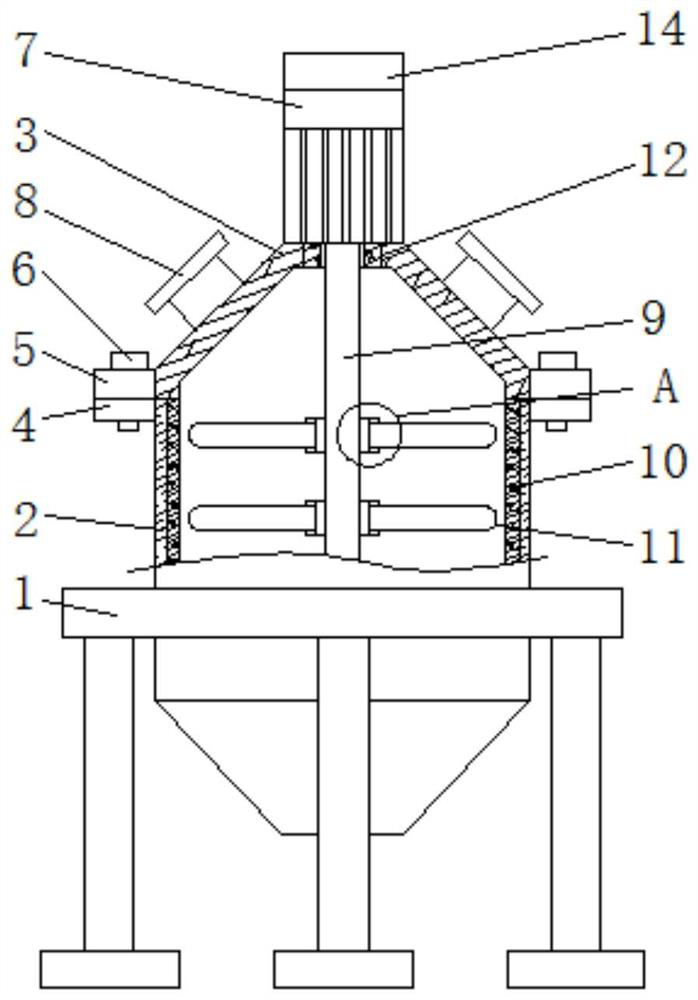

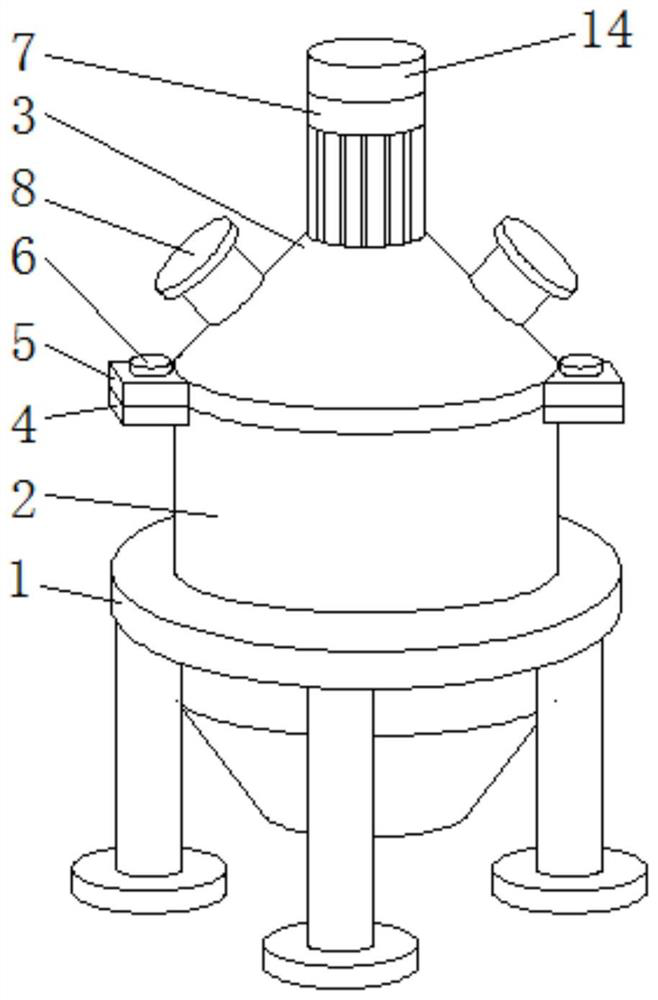

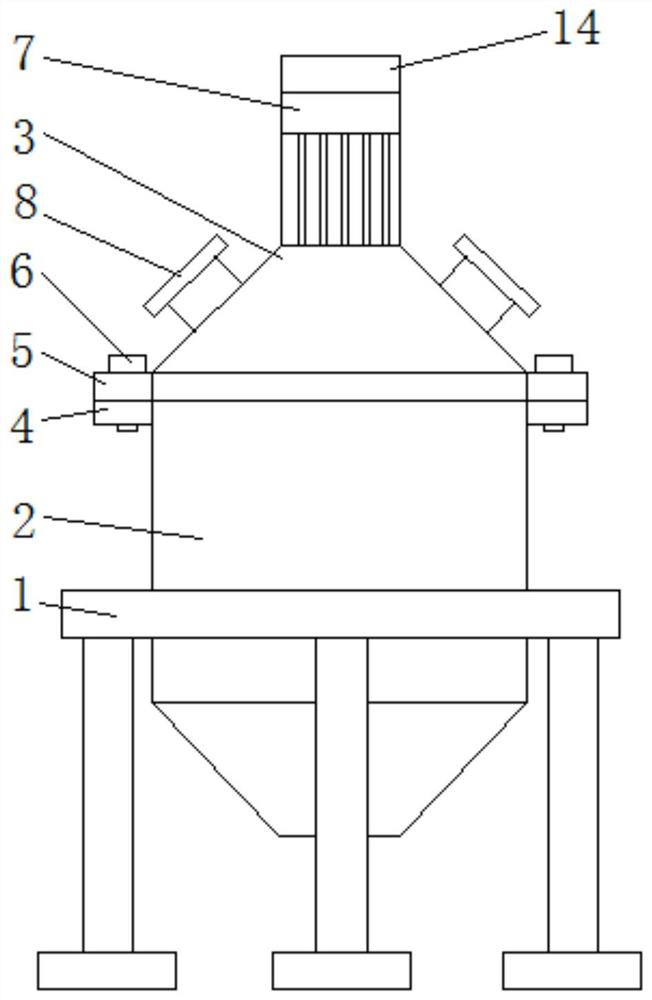

[0033] Embodiment one, by Figure 1-7 Given, the present invention includes a rubber mixing and dissolving system in the production of polystyrene, including a bracket 1, the inner side of the bracket 1 is welded with a shell-2, and the outer side of the shell-2 is fixedly connected with a fixed plate-4, and the fixed plate-4 The shape is the same as that of the fixed plate two 5, the screw rod 6 runs through the inner wall of the fixed plate one 4, the screw rod 6 is threaded with the fixed plate one 4, the top of the shell one 2 is sleeved with the shell two 3, and the shell two 3 The outer side is fixedly connected with a fixed plate 2 5, the inner wall of the fixed plate 5 is threadedly connected with a screw 6, the screw 6 is used to fix the shell 2 3, and the outer side of the shell 2 3 is fixedly connected with a feed port 8, a feed port 8 Through the inner wall of the shell two 3, the feed port 8 is used for adding raw materials, the top of the shell two 3 is fixedly c...

Embodiment 2

[0034] Embodiment two, by Figure 1-7 Given, the present invention includes a rubber mixing and dissolving system in the production of polystyrene, including a bracket 1, the inner side of the bracket 1 is welded with a shell-2, and the outer side of the shell-2 is fixedly connected with a fixed plate-4, and the fixed plate-4 The shape is the same as that of the fixed plate two 5, the screw rod 6 runs through the inner wall of the fixed plate one 4, the screw rod 6 is threaded with the fixed plate one 4, the top of the shell one 2 is sleeved with the shell two 3, and the shell two 3 The outer side is fixedly connected with a fixed plate 2 5, the inner wall of the fixed plate 5 is threadedly connected with a screw 6, the screw 6 is used to fix the shell 2 3, and the outer side of the shell 2 3 is fixedly connected with a feed port 8, a feed port 8 Through the inner wall of the shell two 3, the feed port 8 is used for adding raw materials, the top of the shell two 3 is fixedly c...

Embodiment 3

[0037] Embodiment three, by Figure 1-7 Given, the present invention includes a rubber mixing and dissolving system in the production of polystyrene, including a bracket 1, the inner side of the bracket 1 is welded with a shell-2, and the outer side of the shell-2 is fixedly connected with a fixed plate-4, and the fixed plate-4 The shape is the same as that of the fixed plate two 5, the screw rod 6 runs through the inner wall of the fixed plate one 4, the screw rod 6 is threaded with the fixed plate one 4, the top of the shell one 2 is sleeved with the shell two 3, and the shell two 3 The outer side is fixedly connected with a fixed plate 2 5, the inner wall of the fixed plate 5 is threadedly connected with a screw 6, the screw 6 is used to fix the shell 2 3, and the outer side of the shell 2 3 is fixedly connected with a feed port 8, a feed port 8 Through the inner wall of the shell two 3, the feed port 8 is used for adding raw materials, the top of the shell two 3 is fixedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com