Compound polymer modified bentonite anti-seepage barrier material as well as preparation method and application thereof

A technology of barrier material and bentonite, which is applied in compound polymer modified bentonite anti-seepage barrier material and its preparation and application field, can solve the problems of infiltration of pollutants, general adsorption effect, and impact on anti-seepage performance, etc., and achieve high anti-seepage The effect of osmotic block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

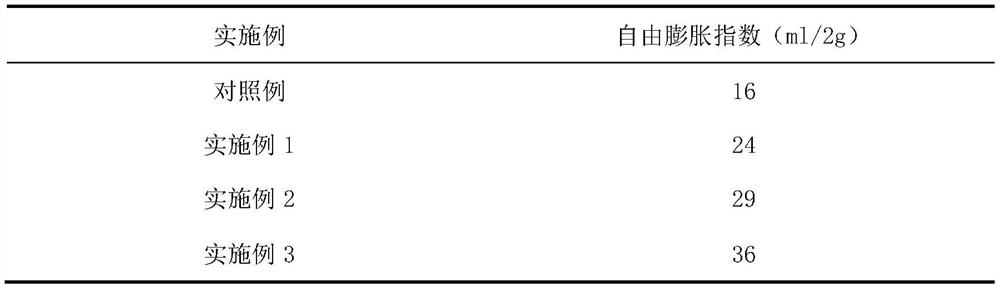

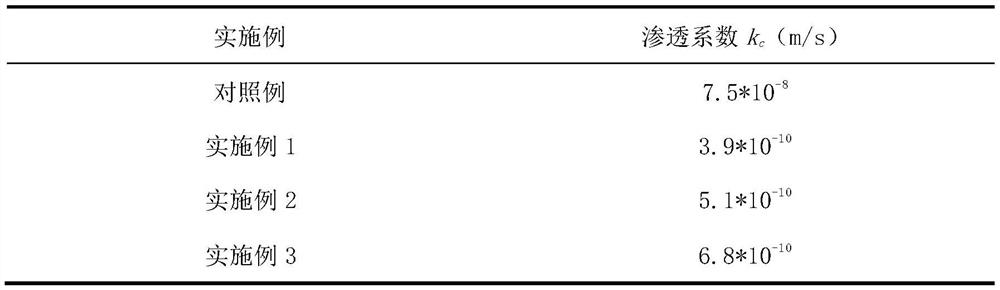

Embodiment 1

[0049] A compound polymer modified bentonite anti-seepage barrier material for high-concentration complex pollutants is applied to vertical barrier barrier backfill by excavation and backfill method.

[0050] Among them, the composite polymer modified bentonite anti-seepage barrier material includes the following components in terms of mass fraction: sodium modified bentonite 94.4%, polyanionic cellulose (PAC) 4.9%, hydroxypropyl methylcellulose (HPMC )0.7%. In addition, the mass ratio of compound polymer modified bentonite anti-seepage barrier material to in-situ sand is 5.3:44.7.

[0051] The preparation process comprises the following steps:

[0052] Step 1) Add sodium modified bentonite, polyanionic cellulose, and hydroxypropyl methylcellulose into a dry powder mixer according to the mass ratio of 94.4:4.9:0.7 and stir for 30 minutes to prepare a compound polymer modified bentonite anti-seepage barrier material ; wherein the dry powder mixer speed is 30r / min;

[0053] S...

Embodiment 2

[0055] A compound polymer modified bentonite anti-seepage barrier material for high-concentration complex pollutants is applied to vertical barrier barrier backfill by excavation and backfill method.

[0056] Among them, the composite polymer modified bentonite anti-seepage barrier material includes the following components by mass fraction: sodium modified bentonite 89.2%, polyanionic cellulose (PAC) 9.4%, hydroxypropyl methylcellulose (HPMC ) 1.4%. In addition, the mass ratio of compound polymer modified bentonite anti-seepage barrier material to in-situ sand is 1.4:11.1.

[0057] The preparation process comprises the following steps:

[0058] Step 1) Add sodium modified bentonite, polyanionic cellulose, and hydroxypropyl methylcellulose into a dry powder mixer according to the mass ratio of 89.2:9.4:1.4 and stir for 30 minutes to prepare a compound polymer modified bentonite anti-seepage barrier material ; wherein the dry powder mixer speed is 30r / min;

[0059] Step 2) M...

Embodiment 3

[0061] A compound polymer modified bentonite anti-seepage barrier material for high-concentration complex pollutants is applied to vertical barrier barrier backfill through excavation and backfill method.

[0062] Among them, the composite polymer modified bentonite anti-seepage barrier material includes the following components by mass fraction: sodium modified bentonite 83.2%, polyanionic cellulose (PAC) 14.7%, hydroxypropyl methylcellulose (HPMC ) 2.1%. In addition, the mass ratio of compound polymer modified bentonite anti-seepage barrier material to in-situ sand is 3:22.

[0063] The preparation process comprises the following steps:

[0064] Step 1) Add sodium modified bentonite, polyanionic cellulose, and hydroxypropyl methylcellulose into a dry powder mixer according to the mass ratio of 83.2:14.7:2.1 and stir for 30 minutes to prepare a compound polymer modified bentonite anti-seepage barrier material ; wherein the dry powder mixer speed is 30r / min;

[0065] Step 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com