Preparation method and application of organic acid activated calcium-based heat carrier

An organic acid, calcium-based technology, applied in the field of preparation of calcium-based heat carrier, can solve the problem of difficulty in suppressing sintering of heat carrier, and achieve the effect of stable pore structure and sintering inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

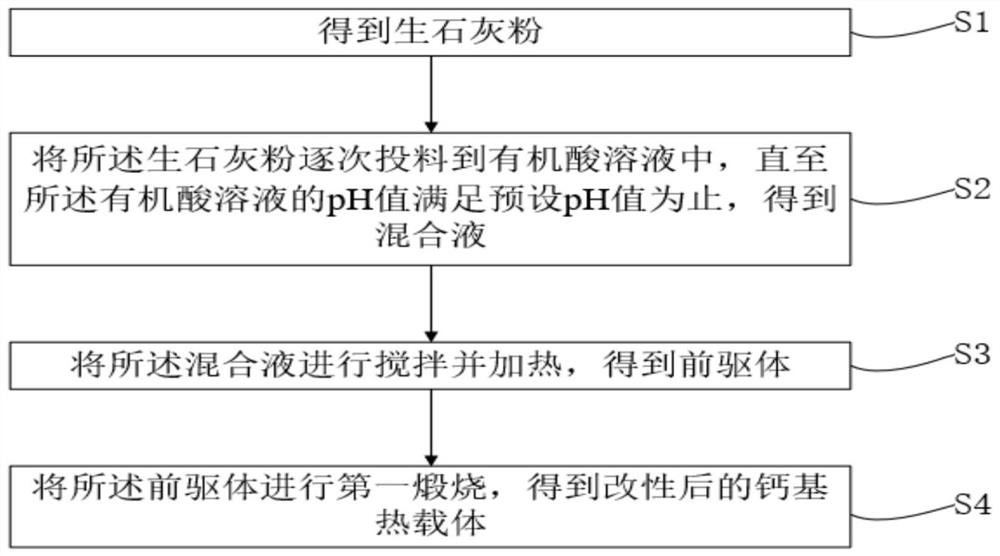

[0046] In one embodiment of this application, as figure 1 Shown, provide a kind of preparation method of the calcium-based heat carrier of organic acid activation, described method comprises:

[0047] S1. obtain unslaked lime powder;

[0048] S2. feeding the quicklime powder into the organic acid solution successively until the pH value of the organic acid solution meets the preset pH value to obtain a mixed solution;

[0049] S3. Stir and heat the mixed solution to obtain a precursor;

[0050] S4. Carrying out the first calcination of the precursor to obtain a modified calcium-based heat carrier;

[0051] Wherein, the concentration of the organic acid solution is 0.05g / mL~0.1g / mL;

[0052] The organic acid solution includes at least one of glycine, citric acid, alanine, formic acid, acetic acid and oxalic acid.

[0053] In this application, the positive effect of the concentration of the organic acid solution being 0.05g / mL~0.1g / mL is that under this concentration conditi...

Embodiment 1

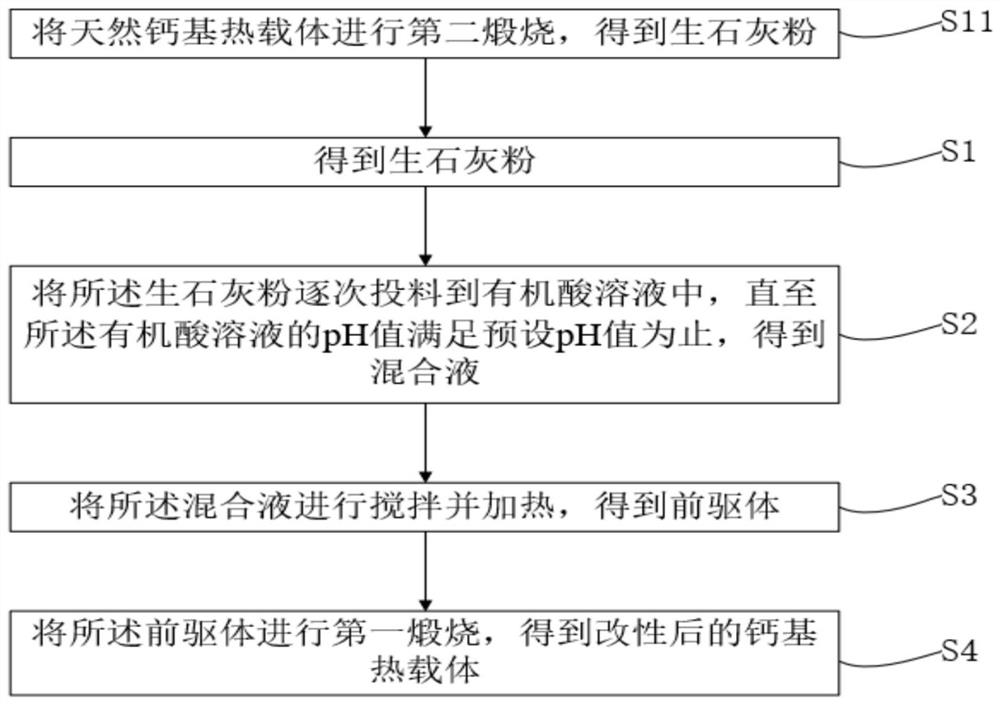

[0083] Such as figure 2 Shown, a kind of preparation method of the calcium-based heat carrier of organic acid activation, described method comprises:

[0084] S11. Carrying out the second calcination of the natural calcium-based heat carrier to obtain quicklime powder;

[0085] S1. obtain unslaked lime powder;

[0086] S2. The unslaked lime powder is fed into the organic acid solution successively until the pH value of the organic acid solution meets the preset pH value to obtain a mixed solution;

[0087] S3. Stir and heat the mixed solution to obtain a precursor;

[0088] S4. Carrying out the first calcination of the precursor to obtain the modified calcium-based heat carrier;

[0089] Among them, the concentration of organic acid solution is 0.08g / mL

[0090] The organic acid solution is glycine, and the natural calcium-based heat carrier is egg shell.

[0091] The temperature of the first calcination is 900° C., the time of the first calcination is 2.5 h, and the tem...

Embodiment 2

[0096] Compare embodiment 2 and embodiment 1, the difference of embodiment 2 and embodiment 1 is:

[0097] The organic acid solution is citric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com