Stirring device and stirring method for preparing aluminum alloy semi-solid composite slurry and application

A technology of stirring device and composite slurry, which is applied in the direction of stirring device, lighting and heating equipment, process efficiency improvement, etc. Uniformity effect and other problems, to achieve the effect of excellent microstructure, fine grain and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

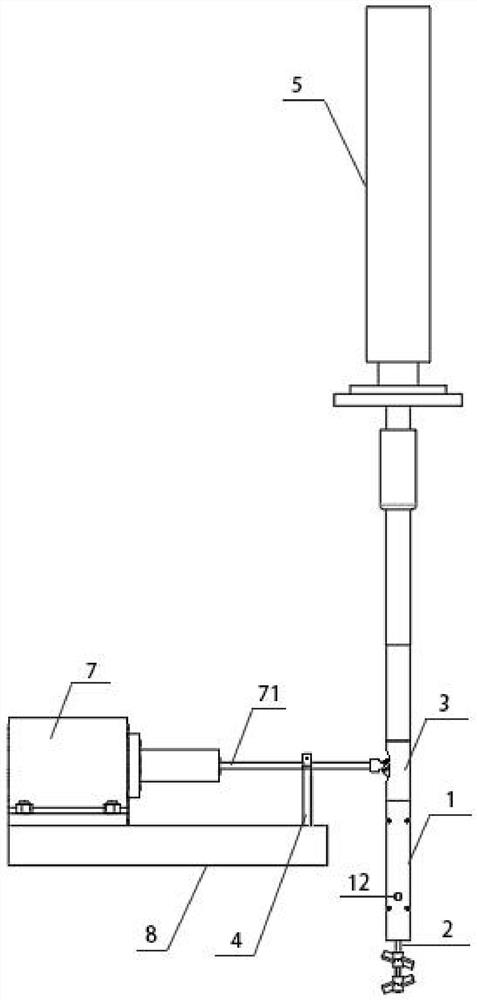

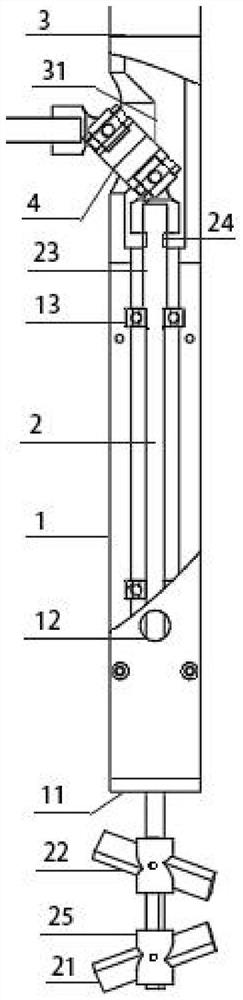

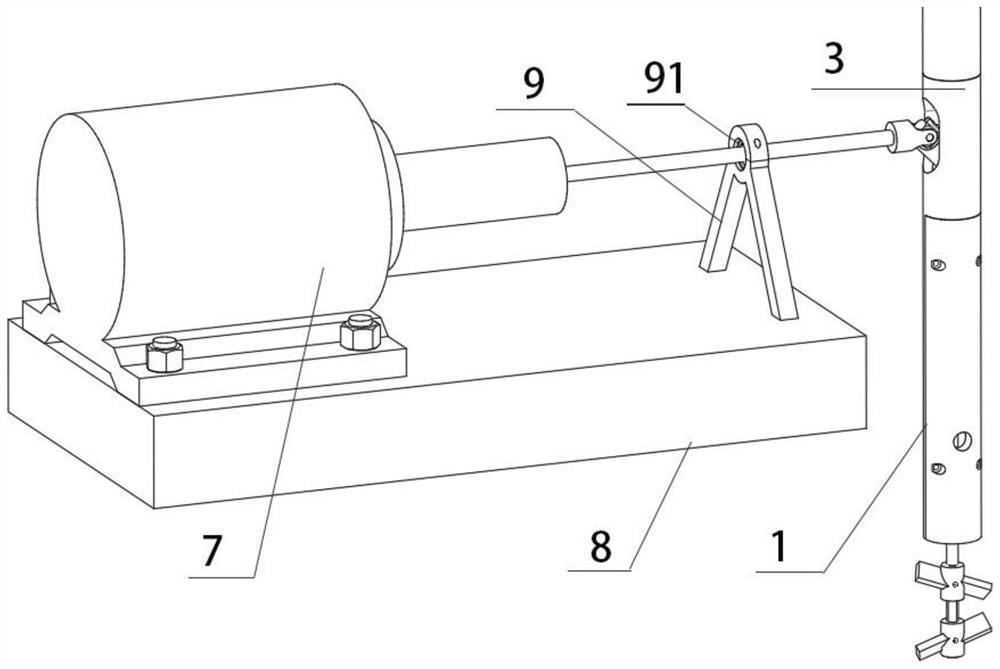

[0045] see Figure 1 ~ Figure 3, this embodiment provides a stirring device for preparing aluminum alloy semi-solid and aluminum-based composite slurry, including a cylinder 1, a stirring rod 2, a mounting base 3, a double-joint universal coupling 4 and an ultrasonic amplitude changer pole 5. The barrel 1 of this embodiment has a cavity inside, and the bottom is provided with a through hole 11 communicating with the cavity, the upper end of the stirring rod 2 is arranged in the cavity through the through hole 11, and the lower end of the stirring rod 2 is provided with a stirring paddle. The installation base 3 is arranged on the upper end of the cylinder body 1, and the inside of the installation base 3 is provided with an installation groove, and the structure of the installation groove matches the structure of the double joint universal coupling, and the installation groove communicates with the above-mentioned cavity. The double-joint universal coupling 4 is installed in...

Embodiment 2

[0048] see Figure 1 ~ Figure 3 , this embodiment provides a stirring device for preparing aluminum alloy semi-solid and aluminum-based composite slurry.

[0049] In order to ensure that the stirring rod 2 can be driven to rotate, a mounting hole 31 is provided on one side of the mounting base 3 in this embodiment, and the mounting hole 31 communicates with the mounting groove, and the mounting hole 31 is used for connecting the output shaft of the drive mechanism Double joint universal coupling 4 transmission connection.

Embodiment 3

[0051] In this embodiment, on the basis of Embodiment 1, in order to ensure that the second phase structure is uniformly dispersed into the aluminum liquid, there is a gap between the stirring rod 2 and the cavity wall in this embodiment, and on the side wall of the cylinder 1 A feed port 12 is provided, and the feed port 12 communicates with the above-mentioned gap. Through the feed port 12, the second phase tissue, such as graphene, can be added into the gap. The generator enables mechanical stirring to be carried out in the center of the ultrasonic field, thereby ensuring the simultaneous action of mechanical stirring and ultrasonic vibration, which is conducive to the formation of a slurry with fine grains, uniform structure, and excellent microstructure.

[0052] The graphene particles added in this embodiment are slowly pushed into between the cylinder 1 and the stirring rod 2 from the feeding port 12 at a constant speed, and are naturally added to the molten aluminum in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com