New-generation synthetic pulmonary surfactant preparation and clinical application thereof

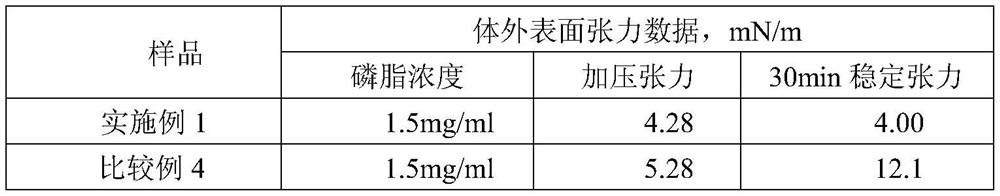

A pulmonary surfactant and preparation technology, applied in the field of new-generation synthetic pulmonary surfactant, can solve the problems of poor stability and low activity of fully synthetic PS preparations, achieve stable and long-lasting curative effect, increase in vitro surface activity, and improve blood oxygen level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] According to the information corresponding to Example 1 in the above table, add all the materials into ethanol (95%, v / v) at 35-45°C, stir until dissolved, and filter while hot; add a buffer solution (tris or Phosphate, sodium chloride, calcium chloride, etc.) (pH = 7.0 ± 0.5), stir quickly until uniform, and remove the organic solvent by circular dialysis or nanofiltration until the solvent residue meets the requirements of the relevant regulations of the Chinese Pharmacopoeia.

[0051] Detect the pH and content of the medicinal solution, supplement the buffer solution according to the test results, and adjust the pH to the specified level (pH=7.0±0.5) if necessary. When necessary, appropriate filtration or other means can be used to remove microorganisms in the liquid medicine.

[0052] Quantitative filling into borosilicate glass control injection bottles (or other pharmaceutical packaging materials) to prepare PS preparations.

Embodiment 2

[0054] According to the information corresponding to Example 2 in the above table, add all the materials into isopropanol (90%, v / v) at 35-45° C., stir until dissolved, and filter while hot; add the buffer solution ( tris or phosphate, sodium chloride, calcium chloride, etc.), stir rapidly until uniform, remove the organic solvent by gradient centrifugation, freeze-dry, and moderately pulverize (or micronize) to obtain the PS preparation.

Embodiment 3

[0056] According to the information corresponding to Example 3 in the above table, all the materials were added into the acidified methanol-chloroform solution kept at 35-45° C., stirred evenly, and filtered.

[0057] After blowing dry with nitrogen gas, oscillate evenly with a buffer solution (tris or phosphate, etc.), and quantitatively dispense into a suspension dosage form. It can also be freeze-dried to produce a freeze-dried product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com