Preparation method and application of graphene oxide modified carboxymethyl chitosan composite hydrogel

A technology of carboxymethyl chitosan and composite hydrogel, which can be applied to medical preparations with non-active ingredients, non-active ingredients of polymer compounds, and medical preparations containing active ingredients, etc. and other problems, to achieve the effect of large specific surface area, increase swelling, and reduce the number of doses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

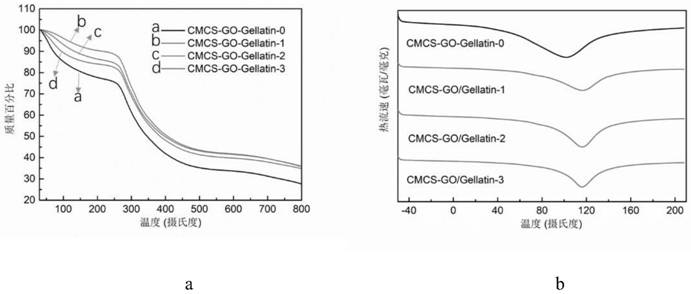

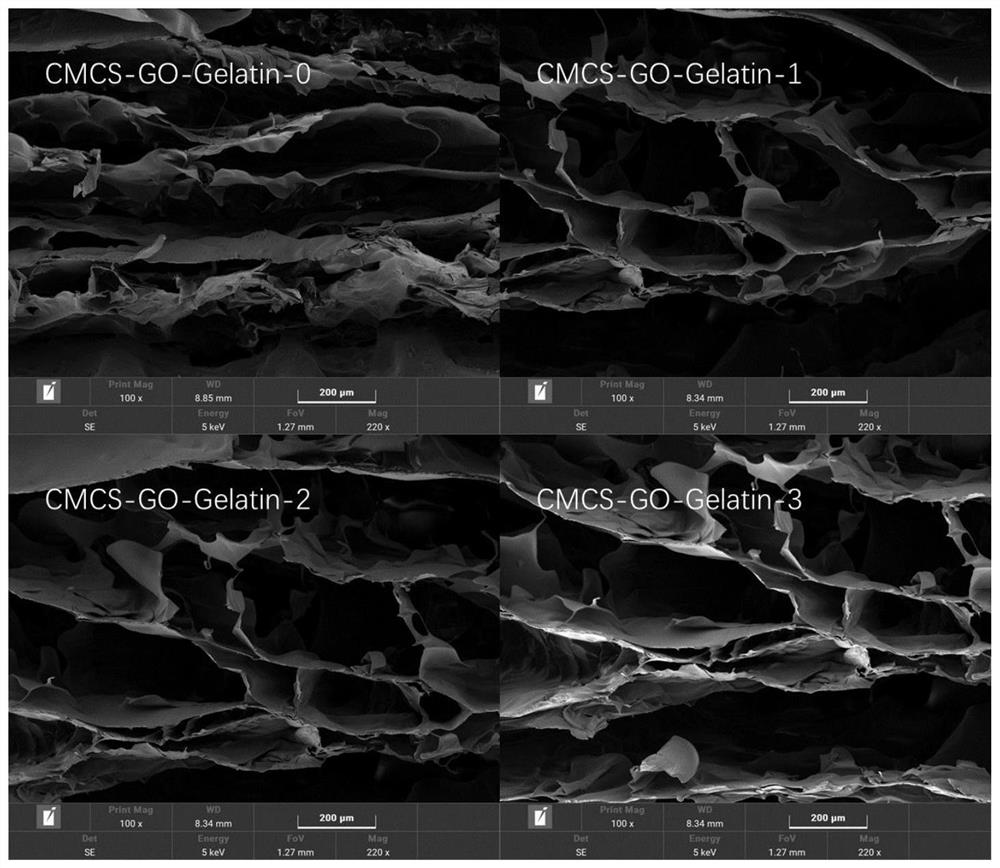

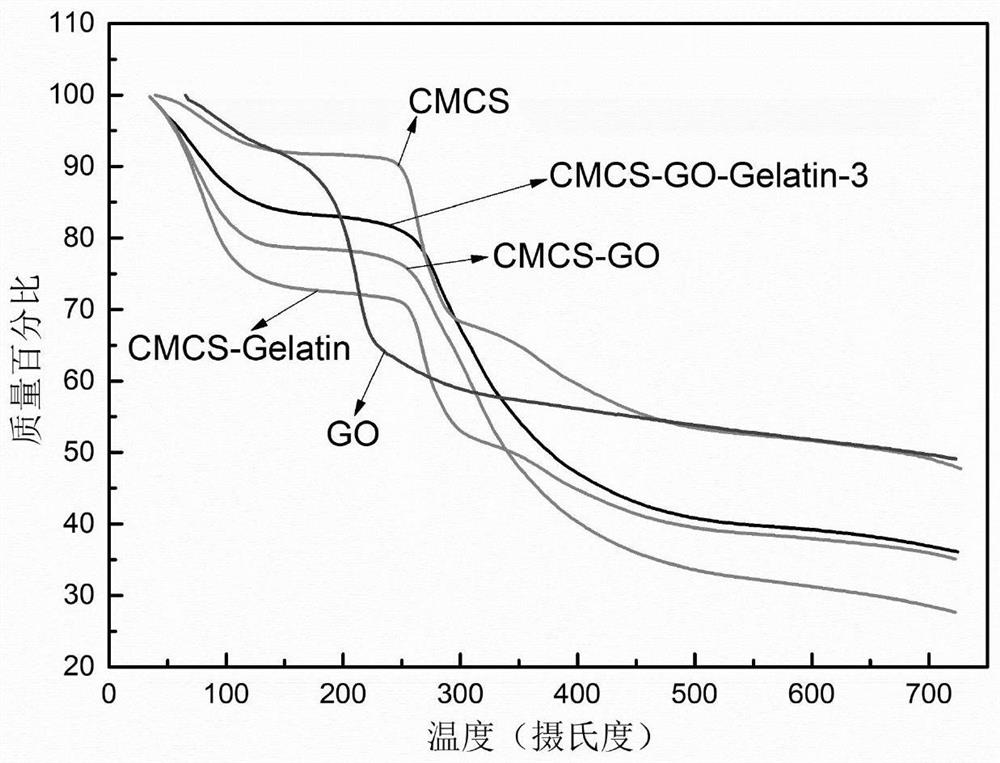

[0032] Example 1: Preparation method and application of a graphene oxide-modified carboxymethyl chitosan composite hydrogel

[0033] Include the following steps:

[0034] (1), dissolve carboxymethyl chitosan in deionized water, and continue magnetic stirring until completely dissolved to obtain a certain mass of carboxymethyl chitosan solution, carboxymethyl chitosan in carboxymethyl chitosan solution The mass concentration is 0.5wt%;

[0035] (2), adding graphene oxide into deionized water, ultrasonic 30min, obtains dispersed graphene oxide solution, the mass concentration of graphene oxide in the graphene oxide solution is 0.5mg / mL;

[0036] (3), get 90 milliliters of carboxymethyl chitosan solution and 10 milliliters of graphene oxide solutions and beaker, and add 1 mL of triphosphoric acid solution, continue magnetic stirring 2h, obtain carboxymethyl chitosan graphene oxide composite solution;

[0037] (4), weigh 0.8g of gelatin and add it into the carboxymethyl chitosan...

Embodiment 2

[0051] Example 2: Preparation method and application of a graphene oxide-modified carboxymethyl chitosan composite hydrogel

[0052] Include the following steps:

[0053] (1), dissolve carboxymethyl chitosan in deionized water, and continue magnetic stirring until completely dissolved to obtain a certain mass of carboxymethyl chitosan solution, carboxymethyl chitosan in carboxymethyl chitosan solution The mass concentration is 5wt%;

[0054] (2), graphene oxide was added into deionized water, ultrasonically dispersed for 30 minutes to obtain a dispersed graphene oxide solution, and the mass concentration of graphene oxide in the graphene oxide solution was 1.5 mg / mL;

[0055] (3), get 70 milliliters of carboxymethyl chitosan solution and 30 milliliters of graphene oxide solutions and beaker, and add triphosphoric acid solution 1mL, continue magnetic stirring 2h, obtain carboxymethyl chitosan graphene oxide composite solution;

[0056] (4) Weigh 1.5g of gelatin and add it to ...

Embodiment 3

[0059] Example 3: Preparation method and application of a graphene oxide-modified carboxymethyl chitosan composite hydrogel

[0060] Include the following steps:

[0061] (1), carboxymethyl chitosan is dissolved in deionized water, continuous magnetic stirring is until fully dissolved, and a certain quality carboxymethyl chitosan solution is obtained; carboxymethyl chitosan in carboxymethyl chitosan solution The mass concentration is 10wt%.

[0062] (2), graphene oxide is added into deionized water, ultrasonic 30min to complete dispersion, obtain graphene oxide solution, the mass concentration of graphene oxide in the graphene oxide solution is 2mg / mL;

[0063] (3), get 50 milliliters of carboxymethyl chitosan solution and 50 milliliters of graphene oxide solutions and beaker, and add triphosphoric acid solution 1mL, continue magnetic stirring 2h, obtain carboxymethyl chitosan graphene oxide composite solution;

[0064] (4) Weigh 2.0 g of gelatin and add it to the carboxymet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com