Stretchable blue-phase liquid crystal elastomer and preparation method thereof

A blue-phase liquid crystal and elastomer technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve problems such as limited mechanical stretchability, and achieve the effects of good mechanical ductility, uniform coloring, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

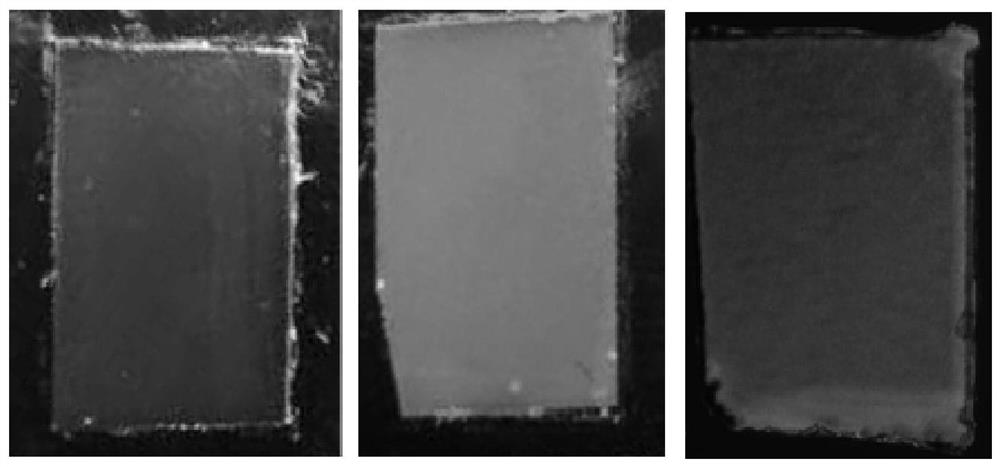

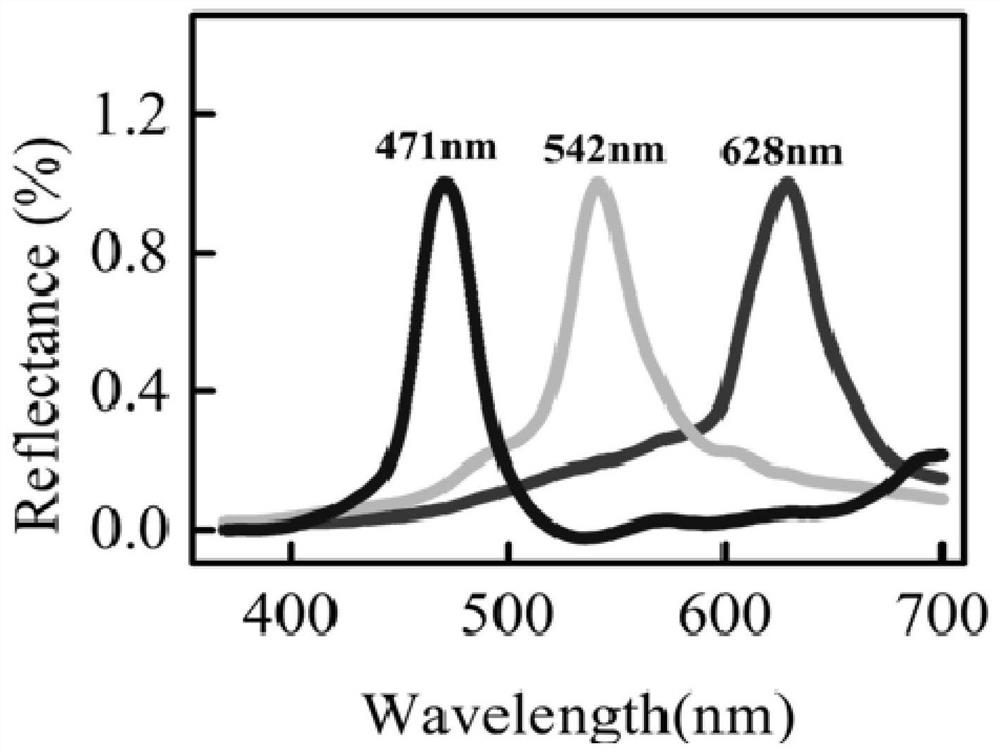

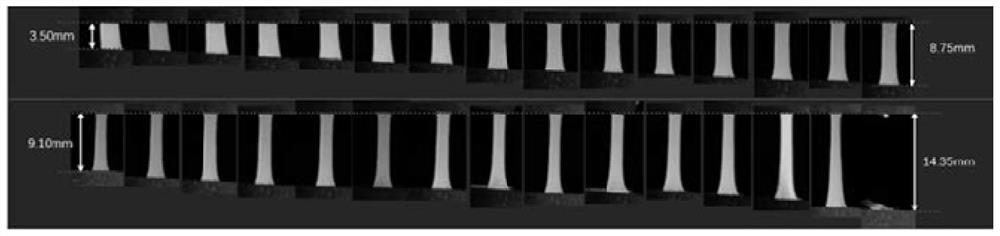

Image

Examples

preparation example Construction

[0082] According to the second aspect of the present invention, there is also provided a method for preparing a stretchable blue phase liquid crystal elastomer, comprising: adding 46 to 48 wt% of achiral small molecule liquid crystal, 38.1 wt% of acrylate photopolymerizable monomer Body, 2-4wt% chiral material, 0.3wt% photoinitiator, mix and heat to isotropy, stir evenly; after cooling to room temperature, add catalyst DPA and stir evenly; then add mercaptan crosslinking monomer EDDET and stir evenly, Obtain a liquid crystal precursor; heat the mixture to the clearing point of the liquid crystal, pour it into a liquid crystal cell with a thickness of 8-60 μm; cool down the temperature of the liquid crystal cell, and let the mixture reach a blue phase state and let it stand for 0-360 min , control the cooling speed within 0.01~10℃ / min; keep the blue phase state under the light intensity of 2mW / cm 2 The above ultraviolet light is irradiated for 10 seconds to 30 minutes, taken ou...

Embodiment 1

[0088] Achiral small-molecule liquid crystals and acrylic esters with mass proportions of 47.2%, 38.1%, 2.8%, and 0.3% (together with the subsequently added catalyst and cross-linking monomer to form a 100% mass) Photopolymerizable monomer C3M is mixed with RM105, chiral material R5011, and photoinitiator IRG184;

[0089] Heat the mixture to 140°C on a hot stage to fully dissolve the above mixture, stir magnetically for 30 minutes, and cool to room temperature to obtain a homogeneous mixture;

[0090] The catalyst DPA with a mass ratio of 0.15% was added to the above mixture, and magnetically stirred at room temperature for 10 minutes;

[0091] Add thiol-based cross-linking monomer EDDET with a mass ratio of 11.4% to the above mixture, and magnetically stir at room temperature for 10 minutes to obtain a liquid crystal precursor;

[0092] The liquid crystal precursor is heated to a clearing point of 35°C, and poured into a parallel-oriented liquid crystal cell with a thickness...

Embodiment 2

[0097] Achiral small-molecule liquid crystals and acrylic esters with mass proportions of 46.9%, 38.1%, 3.1%, and 0.3% (together with the base catalyst and crosslinking monomer added later to form a whole with a mass of 100%) Photopolymerizable monomer C3M is mixed with RM105, chiral material R5011, and photoinitiator IRG184;

[0098] Heat the mixture to 140°C on a hot stage to fully dissolve the above mixture, stir magnetically for 30 minutes, and cool to room temperature to obtain a homogeneous mixture;

[0099] The catalyst DPA with a mass ratio of 0.15% was added to the above mixture, and magnetically stirred at room temperature for 10 minutes;

[0100] Add thiol-based cross-linking monomer EDDET with a mass ratio of 11.4% to the above mixture, and magnetically stir at room temperature for 10 minutes to obtain a liquid crystal precursor;

[0101] Heat the liquid crystal precursor to the clearing point of 35°C, and pour it into a parallel-oriented liquid crystal cell with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com