Multifunctional portable ultrasonic measuring instrument based on PCI/PCIe and use method

An ultrasonic measurement, portable technology, used in force/torque/work measuring instruments, analysis of solids using sonic/ultrasonic/infrasonic waves, measurement devices, etc. The wall thickness and residual stress measurement function, and the lack of portability of the measurement system can solve the problems of the instrument processing results, achieve fast and accurate measurement, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

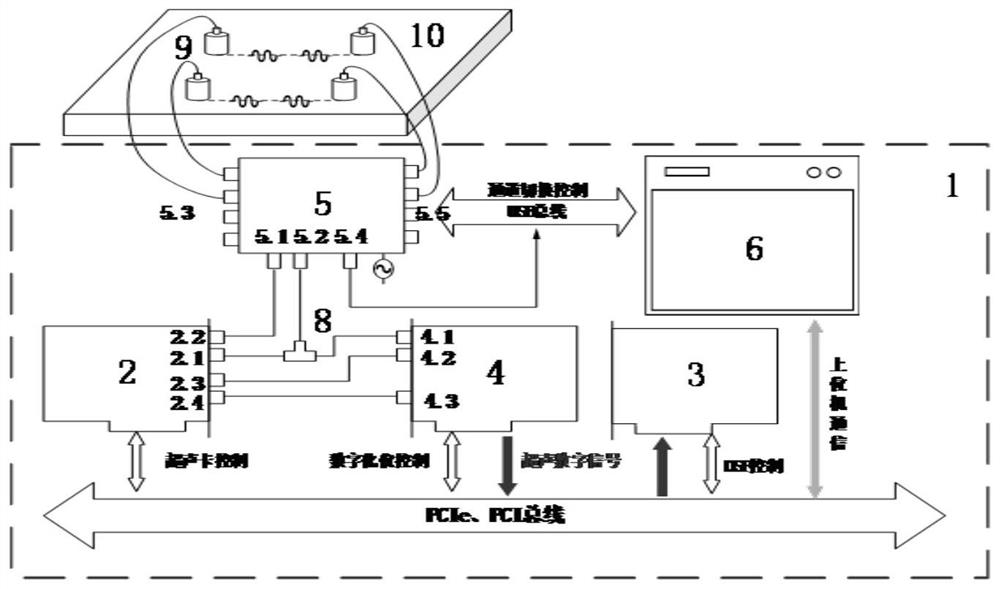

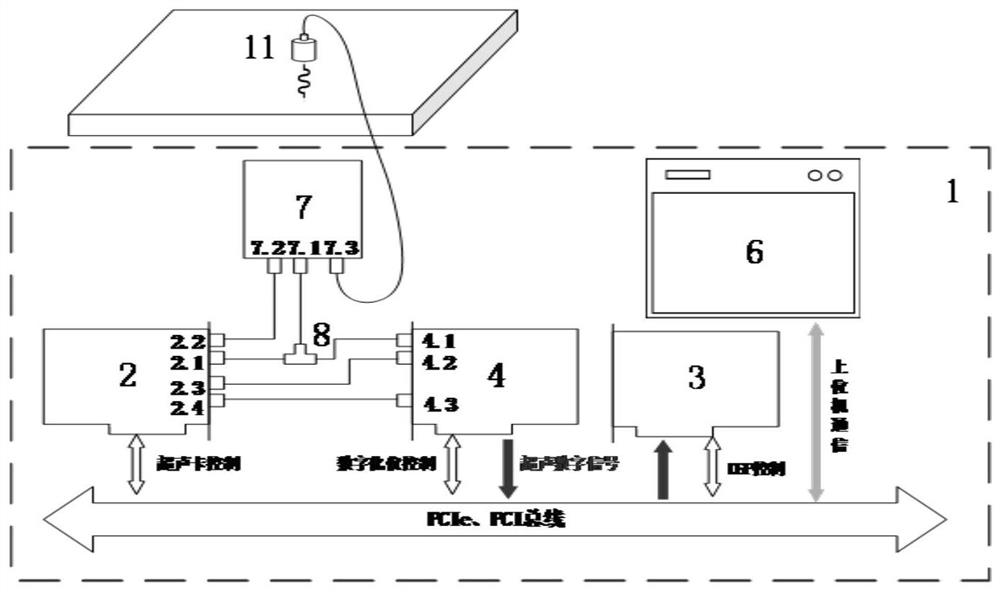

[0026] Specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

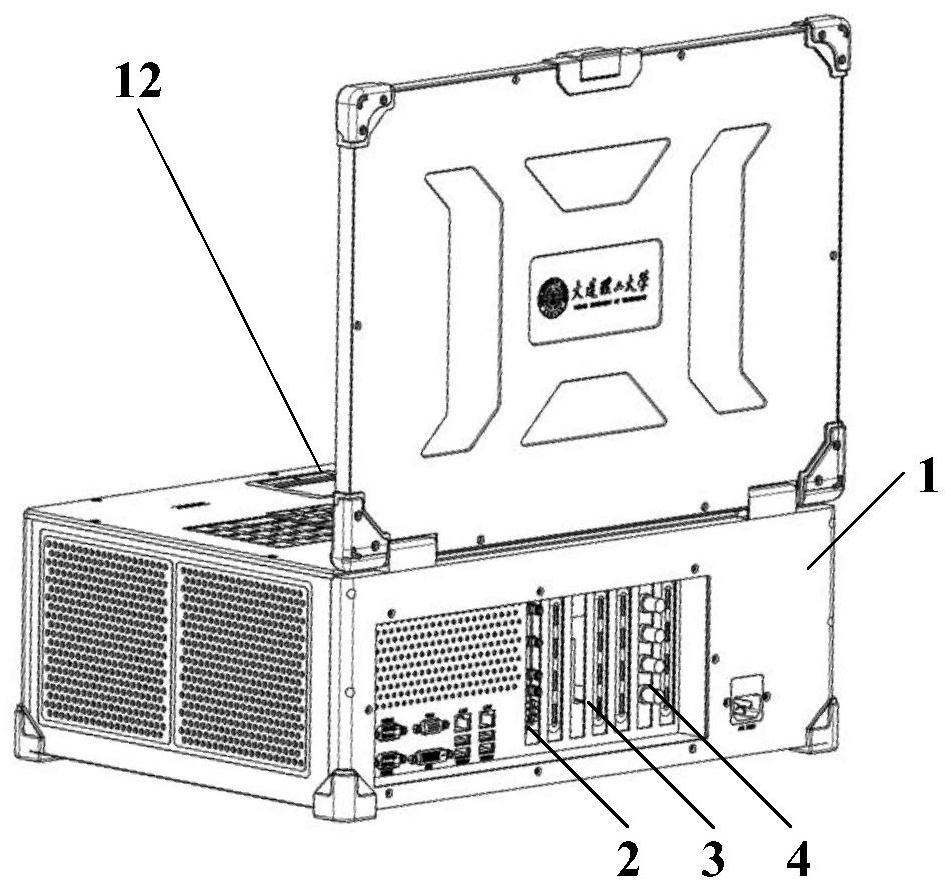

[0027] The main design parameters of the industrial portable machine 1 are as follows: The industrial portable machine 1 is a 17-inch 4U flip-up structure with a size of 445mm×320mm×177mm. There are foot pads at the corners of the chassis to reduce transportation and bump damage; the chassis is designed to install The plastic handle is convenient for handling and field use; the industrial portable machine 1 is designed with multiple PCI slots inside, and the industrial portable machine 1, ultrasonic transmitting and receiving device 2, DSP data processing module 3 and high-speed digitizer 4 are integrated into a multifunctional Portable ultrasonic measuring instrument 12 such as image 3 .

[0028] The main design parameters of the ultrasonic transmitting and receiving device 2 are as follows: it has an excitation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com