Miniaturized broadband low-frequency noise elimination pipeline

A sound-absorbing tube and low-frequency noise technology, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of large space occupation, and achieve the effects of structural optimization, noise energy reduction, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

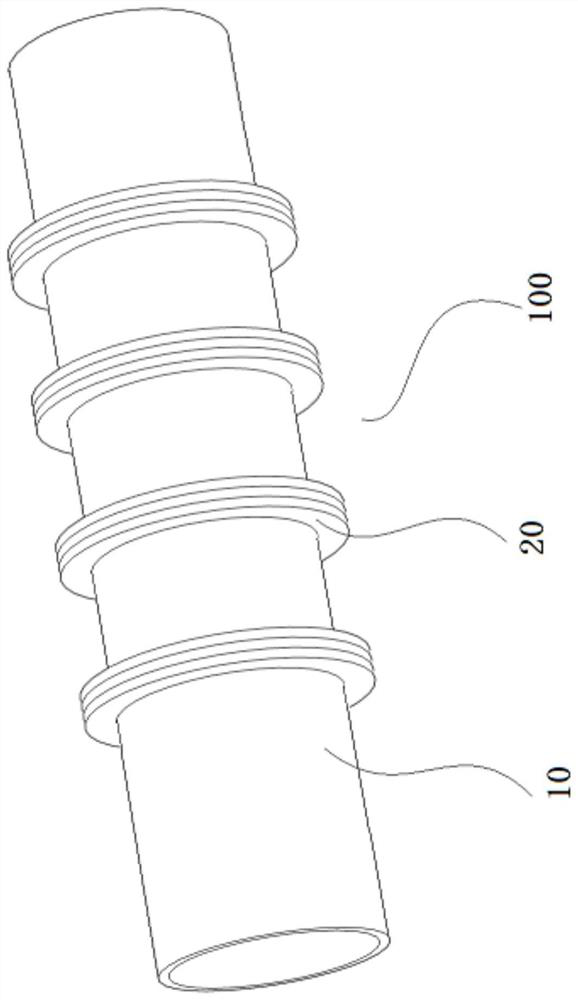

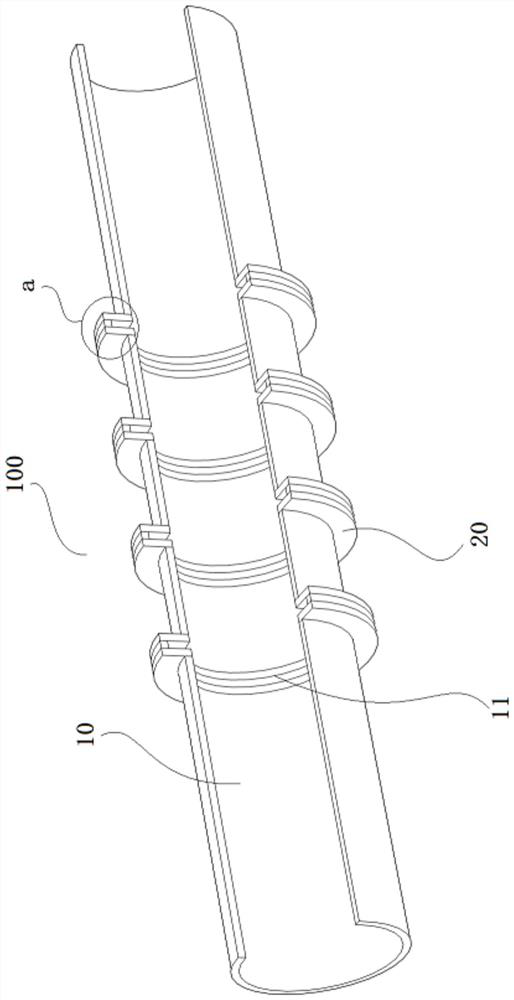

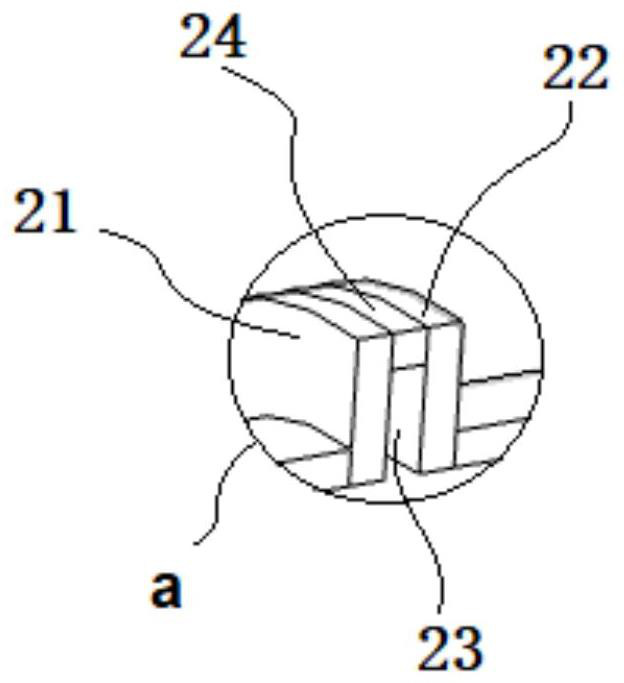

[0041] Such as Figure 1~3 As shown, this embodiment provides a miniaturized broadband low-frequency noise reduction pipeline 100 (hereinafter referred to as the noise reduction pipeline 100), the noise elimination pipeline 100 includes a pipe body 10 and at least one sound-absorbing units 20 , and at least one sound-absorbing unit 20 is arranged at equal intervals along the axial direction of the pipe body 10 . Wherein, the pipe body 10 is provided with at least one slot 11 along its side wall, and the sound absorption unit 20 includes a first plate 21 and a second plate 22 connected to the side walls on both sides of any slot 11, the first plate The part 21 cooperates with the second plate part 22 to form a sound-absorbing channel 23, one end of the sound-absorbing channel 23 communicates with the inner cavity of the pipe body 10, and the other end communicates with the outside.

[0042] It should be noted that the muffler pipeline in this embodiment is mainly used to block...

Embodiment 2

[0056] On the basis of Embodiment 1, this embodiment further provides a muffler pipeline 100, such as Figure 4 As shown, the difference compared with Embodiment 1 is that the second plate 22 in the muffler pipeline 100 includes an extension 221 extending to the inner cavity of the pipe body 10, and the sound absorption unit 10 also includes a The arc-shaped wall 25 in the inner cavity is connected to the extension part 221 , and the extension part 221 , the arc-shaped wall 25 , and the inner wall of the tube body 10 cooperate to form a side wall channel 26 . Continue to refer to Figure 4 As shown, when the airflow and sound waves in the pipe body 10 flow in the direction indicated by the arrow, part of the sound waves will flow into the side wall flow channel 26, thereby entering the sound absorption channel 23 for low-frequency sound absorption.

[0057] This embodiment does not limit the connection position between the extension part 221 and the arc-shaped wall 25, but in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com