Health-care mask and manufacturing method thereof

A manufacturing method and mask technology, applied in botany equipment and methods, tools for sewing clothes, chemicals for biological control, etc., can solve problems such as threats to human health and safety, achieve human and natural environment friendliness, improve The effect of wearing experience and enhancing the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

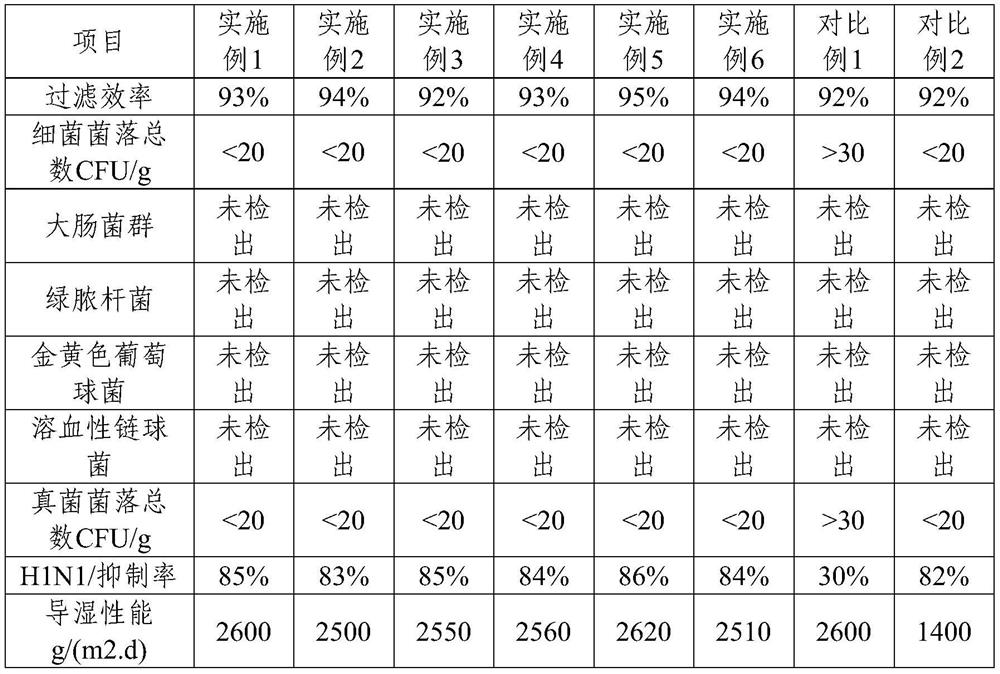

Examples

Embodiment 1

[0019] A manufacturing method of a health-care mask, characterized in that: the health-care mask includes a waterproof layer, a theaflavin-impregnated layer, a filter layer and a skin-friendly layer from the outside to the inside, and the material is non-woven fabric, and the preparation method of the theaflavin-impregnated layer is as follows: : Add 10 parts of theaflavin to 30 parts of water, stir and dissolve to form a theaflavin solution, soak the non-woven material for 5 minutes, then use 300W ultrasonic wave for 1 minute, take it out and dry it, the drying temperature is 40°C , to obtain the theaflavin impregnated layer; the waterproof layer includes the following components by weight: 2 parts of silica gel, 0.5 part of antioxidant 168, and 0.5 part of dispersant vinyl propionate wax; the edges of each layer are heat-sealed by a composite machine Connect to form a mask body. The heat-sealing connection conditions of the composite machine are pressure of 0.15MPa, temperatu...

Embodiment 2

[0021] A manufacturing method of a health-care mask, characterized in that: the health-care mask includes a waterproof layer, a filter layer, a theaflavin-impregnated layer and a skin-friendly layer from outside to inside, and the material is non-woven fabric, and the surface of the filter layer also contains activated carbon, The production method of the theaflavin impregnation layer is as follows: add 30 parts of theaflavin to 60 parts of solvent ethyl acetate, stir and dissolve to form the theaflavin solution, soak the non-woven material for 15 minutes, and then use 300W ultrasonic wave for treatment After 5 minutes, take it out and carry out drying treatment at a drying temperature of 55° C. to obtain the theaflavin impregnated layer; the waterproof layer includes the following ingredients in parts by weight: 8 parts of silica gel, 1 part of antioxidant 1076, 2 parts of dispersant acrylic wax part; the edges of each layer are heat-sealed and connected by a compound machine ...

Embodiment 3

[0023]A manufacturing method of a health-care mask, characterized in that: the health-care mask includes a waterproof layer, a theaflavin-impregnated layer, a filter layer and a skin-friendly layer from the outside to the inside, and the material is non-woven fabric, and the preparation method of the theaflavin-impregnated layer is as follows: : Add 20 parts of theaflavin and 1 part of essence 2-heptanone into 45 parts of propyl acetate wt%:isopropyl acetate wt%=3:1 solvent, stir and dissolve to form theaflavin and essence solution, After the non-woven material is soaked for 10 minutes, it is then treated with 300W ultrasonic waves for 3 minutes, taken out and dried at 45°C to obtain the theaflavin-impregnated layer; the waterproof layer includes the following ingredients in parts by weight: silica gel 2 parts, 1 part of antioxidant 164, 2 parts of dispersant maleic acid grafted polybutylene wax; the edges of each layer are heat-sealed and connected by a compound machine to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com