Preparation method and application of manganese oxide-loaded molecular sieve composite material

A composite material and manganese oxide technology, applied in the field of preparation of molecular sieve composite materials, can solve the problems of inability to industrialize production, secondary pollution, easy desorption, etc., and achieve the effects of easy industrialization, high purification rate, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

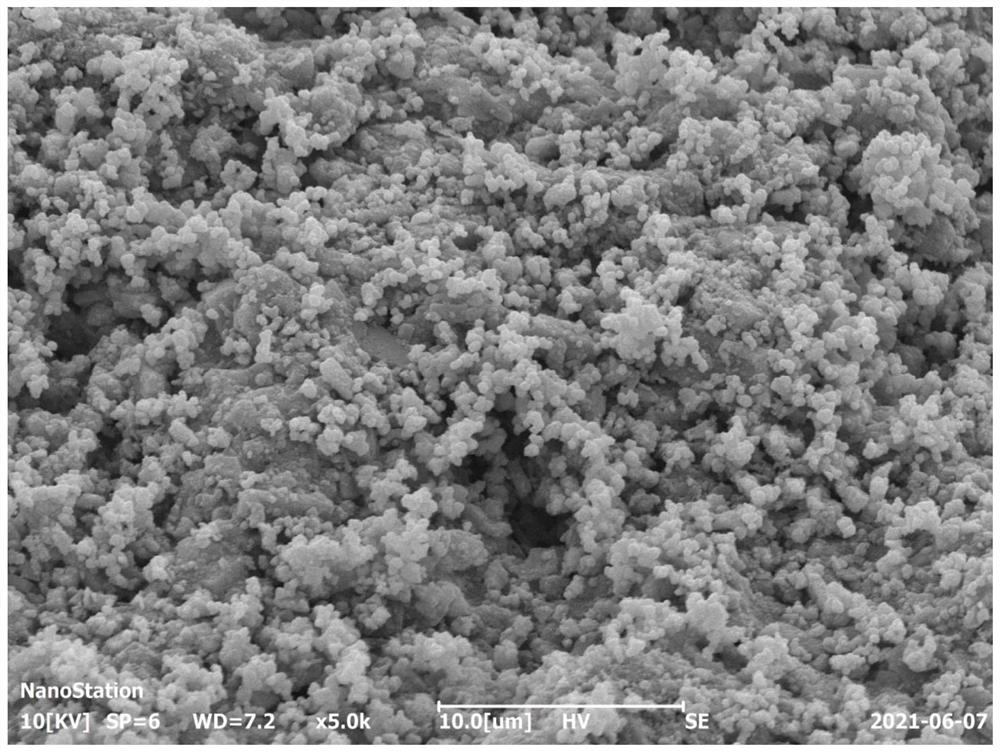

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of the molecular sieve composite material of loaded manganese oxide, comprising the following steps:

[0031] S1, carry out acidification heat treatment to molecular sieve and dry, put the molecular sieve after drying into hydrogen peroxide solution to soak and take out, then place in N at 600~800 ℃ 2 and H 2 Take out the mixed gas after reacting for a preset time;

[0032] S2, put the molecular sieve obtained in step S1 into the divalent manganese solution, add potassium permanganate solution after dipping, and stir to react;

[0033] S3, washing and drying the molecular sieve obtained in step S2 to obtain a finished product;

[0034] In step S2, the mass concentration of the molecular sieve in the divalent manganese solution is 0.1 to 1 g / L; the ratio of the addition of the divalent manganese solution to the potassium permanganate solution is (1 to 3): (1 to 3).

[0035] The preparation method of the manganese ox...

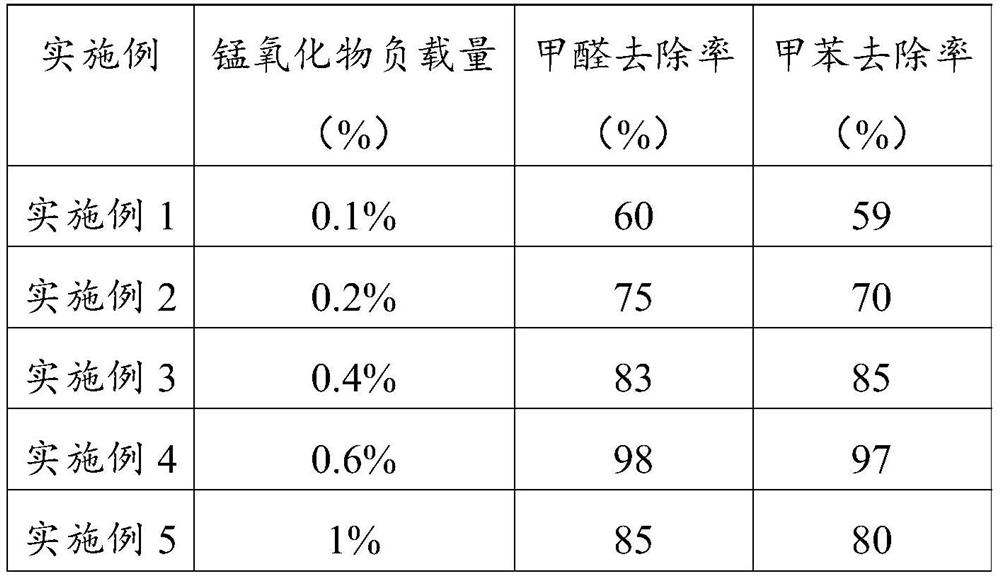

Embodiment 1

[0047] A preparation method of a manganese oxide-loaded molecular sieve composite material, comprising the following steps:

[0048] S1. Take 2 g of ZSM-5 molecular sieve with a silicon-alumina ratio of 220, add it to 100 mL of a sulfuric acid solution with a concentration of 0.5 mol / L, and perform an acidification heat treatment for 80 min under stirring in a water bath at 80 °C. Dry to constant weight.

[0049] S2. Put the dried molecular sieve into a hydrogen peroxide solution with a mass concentration of 0.5 mol / l, soak it for 40 minutes, take it out, and then place it in N at 800°C. 2 and H 2 Take out after 80min of reaction in the mixed gas.

[0050] S3, the ZSM-5 molecular sieve obtained in step S2 is immersed in 100 mL of manganese sulfate solution with a concentration of 0.05 mol / L, and after immersion for 30 min, a potassium permanganate solution with a concentration of 0.05 mol / L is added dropwise under stirring, The total dropwise amount of potassium permanganat...

Embodiment 2

[0053] A preparation method of a manganese oxide-loaded molecular sieve composite material, comprising the following steps:

[0054] S1. Take 2 g of ZSM-11 molecular sieve with a silicon-alumina ratio of 300, add it to 100 mL of a sulfuric acid solution with a concentration of 0.5 mol / L, and stir under the heating condition of a water bath at 80 °C for 80 minutes of acidification heat treatment. Dry to constant weight.

[0055] S2. Put the dried molecular sieve into a hydrogen peroxide solution with a mass concentration of 1 mol / l, soak it for 30 minutes, take it out, and then place it in N at 700°C. 2 and H 2 Take out after 60min of reaction in the mixed gas.

[0056] S3, the ZSM-11 molecular sieve obtained in step S2 is immersed in 100 mL of manganese sulfate solution with a concentration of 0.05 mol / L, and after immersion for 30 min, a potassium permanganate solution with a concentration of 0.05 mol / L is added dropwise under stirring, The total dropwise amount of potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com