Pouring system capable of preventing molten iron from overflowing and improving precision

A pouring system and overflow technology, which is applied to the equipment for transporting casting molds, casting molding equipment, casting molds, etc., can solve the problems of low production efficiency, restricting product production, and easy occurrence of danger, so as to reduce the loss of molten iron and ensure production. The effect of process and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

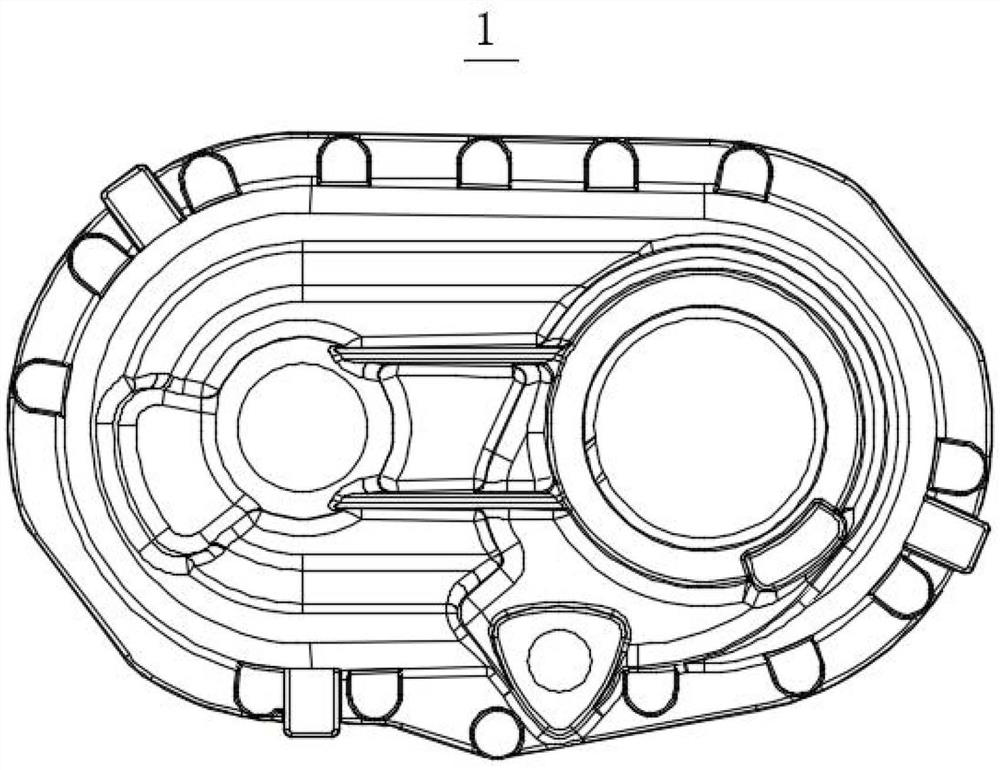

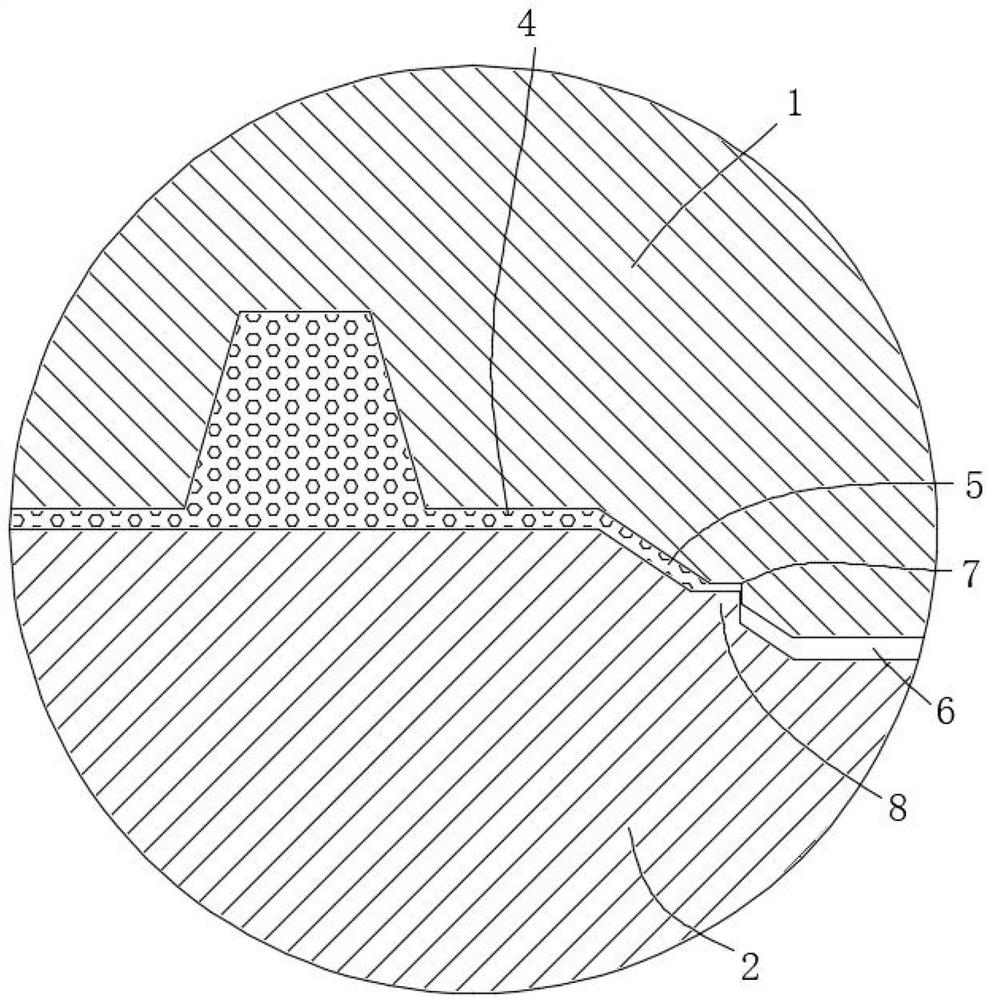

[0031] Please combine Figure 1 to Figure 2 , a pouring system for preventing molten iron overflow and improving precision, including a lower mold base 2 and an upper mold base 1 adapted to be installed on the lower mold base 2, and the bottom of the upper mold base 1 has an inwardly recessed groove. There is a mold cavity on the groove wall of one side away from the lower mold base 2 in the groove. The top of the lower mold base 2 has a platform that protrudes upwards and is adapted to the groove, and the top of the platform has a core that is adapted to the cavity.

[0032] When the mold is closed, a gap area is formed between the groove and the table. The gap area includes a horizontal gap 1 4, an inclined gap 5 and a horizontal gap 2 6. The height of the horizontal gap 1 4 in the vertical direction is higher than that of the horizontal gap 2 6, and the beginning and the end of the inclined gap are respectively connected with the horizontal gap 1 4 and the horizontal gap 2...

Embodiment 2

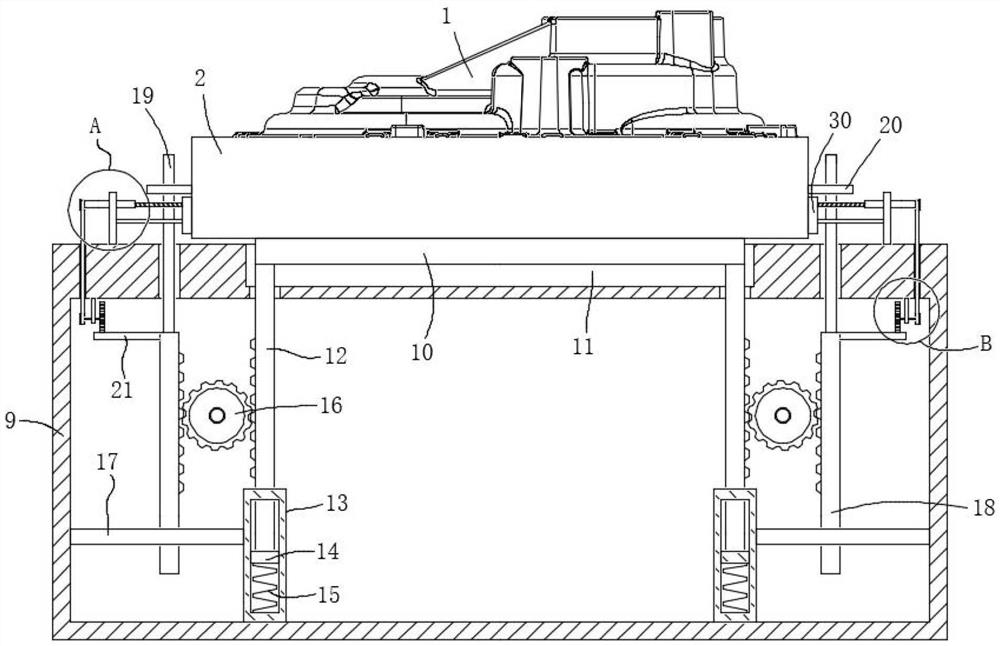

[0038] Please combine Figure 3 to Figure 6 , This embodiment is an improved solution of Embodiment 1. The pouring system also includes a workbench 9 for supporting the lower mold base 2, and a positioning mechanism for positioning the lower mold base 2 is provided on the workbench 9.

[0039]A board groove 11 is opened on the top of the workbench 9, and a hollow cavity (not shown) is provided in the body of the workbench 9. The positioning mechanism includes a carrier plate 10 arranged above the notch of the plate groove 11, and two vertically distributed racks-12 are relatively slidingly inserted in the plate groove 11, and the tops of the two racks-12 are fixed on the carrier plate respectively. 10 on both sides of the bottom. The bottom of each rack one 12 penetrates into the hollow cavity and elastically connects with the bottom cavity wall of the hollow cavity. In this embodiment, a through groove (not shown) through which the rack one 12 can freely pass is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com