Washing method of ternary precursor

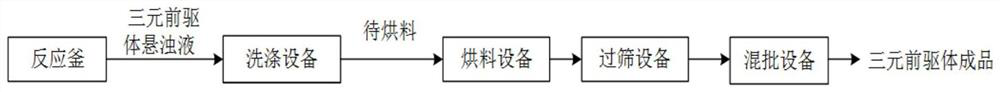

A washing method and precursor technology, applied in the direction of chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems of drying equipment damage, prolonging the drying time, and high water content of the drying material, so as to achieve easy drying, The effect of loose microscopic appearance and excellent washing consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

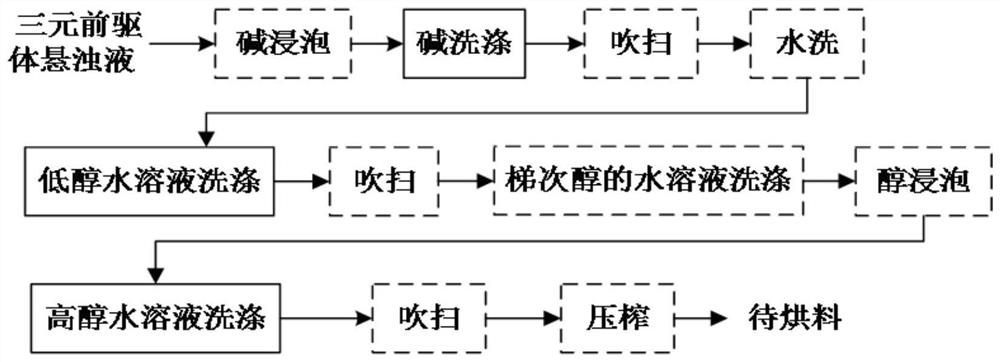

Method used

Image

Examples

Embodiment 1

[0049] In this example, the synthesis steps of the ternary precursor are as follows:

[0050] S1: Put the soluble transition mixed metal salt (nickel, cobalt, manganese or aluminum) and sodium hydroxide solution, complexing agent, etc. into the reactor and stir in parallel, control the stirring frequency to 40Hz, and the temperature in the reactor to 60°C. The pH is 10.8-11.3, the reaction time is 4h, and the ternary precursor is obtained by co-precipitation;

[0051] S2: Transfer the ternary precursor to the alkali immersion tank after removing the mother liquor, control the concentration of sodium hydroxide in the alkali immersion tank to 1.5mol / L, the temperature to 50-60°C, the stirring frequency to 15Hz, and the alkali immersion time to 5min , transfer the ternary precursor with alkali solution to the plate and frame filter press through the feed pipe, first use 0.2mol / L sodium hydroxide solution at 40-45°C as the alkali washing solution for 10 minutes, and then Wash with ...

Embodiment 2

[0056] In this embodiment, step S1 and step S3 in the synthesis steps of the ternary precursor are the same as in embodiment 1, and step S2 is:

[0057] Remove the mother liquor from the ternary precursor and transfer it to an alkali immersion tank. Control the concentration of sodium hydroxide in the alkali immersion tank to 1.5mol / L, the temperature is 50-60°C, the stirring frequency is 15Hz, and the alkali immersion time is 5min. The feeding pipe transfers the ternary precursor with alkali solution to the plate and frame filter press, first washes it with 0.2mol / L sodium hydroxide solution at 40-45°C as the alkali washing solution for 10 minutes, and then washes it with 60 Wash with an aqueous solution of ethanol with a mass fraction of 10% at ~65°C for 30 minutes, wash with an aqueous solution of ethanol with a mass fraction of 50% at 55 to 60°C for 10 minutes, wash with an aqueous solution of 85% ethanol at 50°C for 5 minutes, and then wash with 40 0.5 MPa compressed air ...

Embodiment 3

[0059] In this embodiment, step S1 and step S3 in the synthesis steps of the ternary precursor are the same as in embodiment 1, and step S2 is:

[0060] Remove the mother liquor from the ternary precursor and transfer it to an alkali immersion tank. Control the concentration of sodium hydroxide in the alkali immersion tank to 1.5mol / L, the temperature to 50-60°C, the stirring frequency to 15Hz, and the alkali immersion time to 5min. The feeding pipe transfers the ternary precursor with alkali solution to the plate and frame filter press, first washes it with 0.2mol / L sodium hydroxide solution at 40-45°C as the alkali washing solution for 10 minutes, and then washes it with 60 Wash with pure water at ~65°C for 30min, then wash with 10% ethanol aqueous solution at 60~65°C for 30min, wash with 85% ethanol aqueous solution at 50°C for 5min, compress with 0.5MPa at 40°C The air was purged for 8 minutes to obtain the material to be baked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com