Wiredrawing yoghurt for private kitchen and preparation method thereof

A drawing and yogurt technology, which is applied in the field of drawing yogurt and its preparation in private kitchens, can solve problems such as complex ingredients, and achieve the effect of simple ingredients, strong drawing characteristics, and high taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

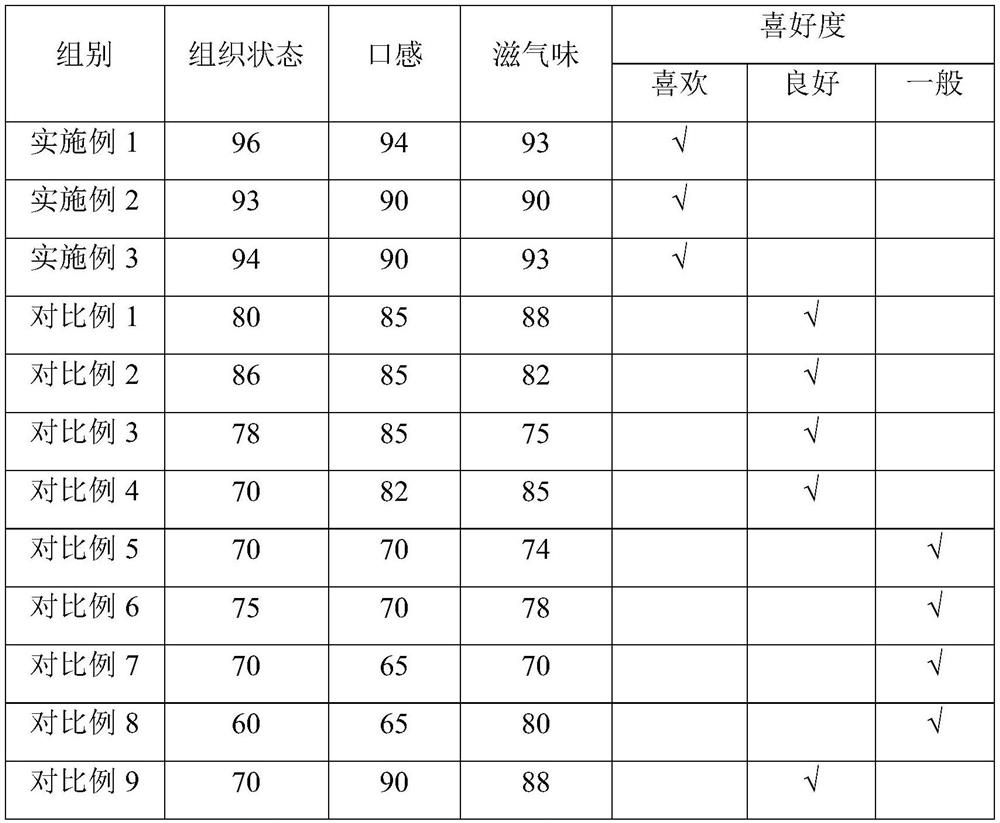

Embodiment 1

[0047] Example 1 Preparation of a private kitchen brushed yoghurt

[0048] S1. 1500g of raw milk that was negative for antibiotics and less than 48h after milking was filtered through RO membrane until the milk protein content was 4.8wt%, to obtain concentrated milk;

[0049] S2. Divide the concentrated milk obtained in S1 into 2 parts at 65°C, use 0bar and 200bar pressures to homogenize and remix, stir at 300rpm / min for 10min, sterilize at 95°C for 5min, and then cool to 43 ℃, to obtain 1000g of cooled milk;

[0050] S3. Add 0.025 g of starter to the cooled milk obtained in S2, and leave it to ferment at 43° C. to pH 4.75 to obtain fermented milk;

[0051] S4. The fermented milk obtained in step S3 is stirred at a speed of 300 rpm / min to break the emulsion, cooled to 18°C, and post-cooked at 4°C for 12 hours to obtain the private kitchen brushed yoghurt;

[0052] Wherein, the starter is composed of Streptococcus thermophilus and Lactobacillus bulgaricus, and the dosage rati...

Embodiment 2

[0053] Example 2 Preparation of a private kitchen brushed yoghurt

[0054] S1. 1250g of raw milk that was negative for antibiotics and less than 48h after milking was filtered through RO membrane until the milk protein content was 4.0wt%, to obtain concentrated milk;

[0055] S2. Divide the concentrated milk obtained in S1 into 2 parts at 65°C, homogenize at 100bar and 200bar respectively and mix again, stir at 500rpm / min for 5min, sterilize at 96°C for 4min, and then cool to 39°C , to obtain 950g cooled milk;

[0056] S3. Add 0.02 g of starter to the cooled milk obtained in S2, and leave it to ferment at 32° C. to pH 4.6 to obtain fermented milk;

[0057] S4. The fermented milk obtained in step S3 is stirred at a speed of 600 rpm / min to break the emulsion, cooled to 15° C., and post-cooked at 5° C. for 18 hours to obtain the private kitchen brushed yoghurt;

[0058] Wherein, the starter is composed of Streptococcus thermophilus and Lactobacillus bulgaricus, and the dosage r...

Embodiment 3

[0059] Example 3 Preparation of a private kitchen brushed yoghurt

[0060] S1. 1650g of raw milk that was negative for antibiotics and less than 48 hours after milking was filtered through RO membrane until the milk protein content was 4.8wt%, to obtain concentrated milk;

[0061] S2. Divide the concentrated milk obtained in S1 into 3 parts at 70°C, use 0bar, 100bar, and 200bar pressures to homogenize and remix, then stir at a speed of 100rpm / min for 15min, sterilize at 93°C for 6min, and then cool to 44°C to obtain 1100g of cooled milk;

[0062] S3. Add 0.04 g of starter to the cooled milk obtained in S2, and leave it to ferment at 44° C. to pH 4.8 to obtain fermented milk;

[0063] S4. The fermented milk obtained in step S3 is stirred at a speed of 600 rpm / min to break the emulsion, cooled to 25°C, and post-cooked at 3°C for 24 hours to obtain the private kitchen brushed yoghurt;

[0064] Wherein, the starter is composed of Streptococcus thermophilus and Lactobacillus bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com