Deep coal chemical wastewater treatment fluidization equipment

A coal chemical wastewater and fluidization technology, applied in the direction of oxidized water/sewage treatment, heating water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of toxic and harmful substances, high energy consumption, poor biodegradability, etc., to achieve Enhance the integrity and linkage, reduce the effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

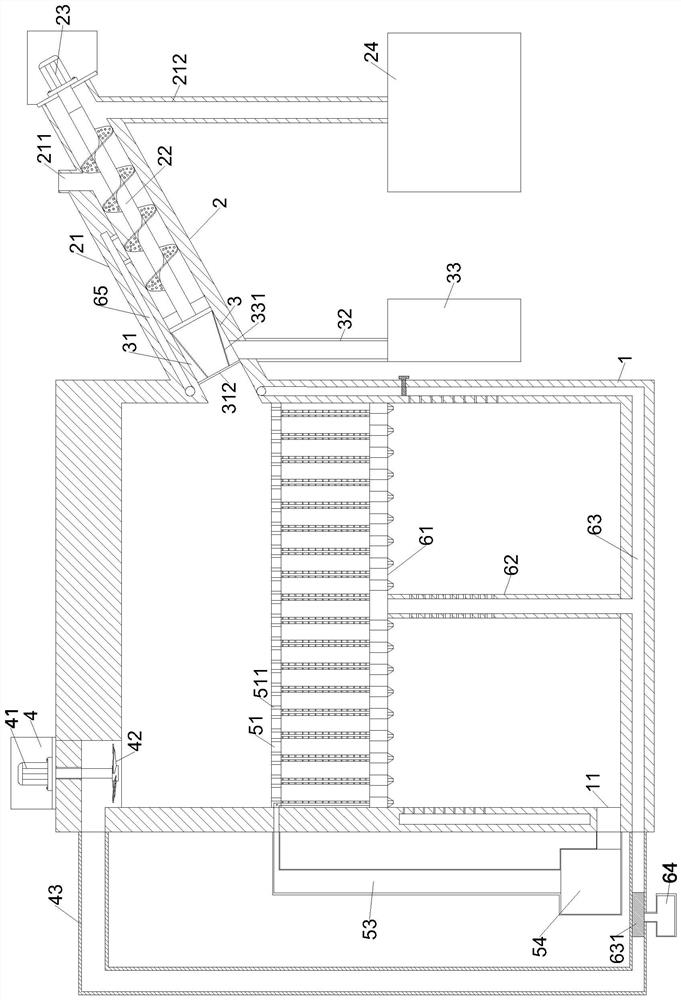

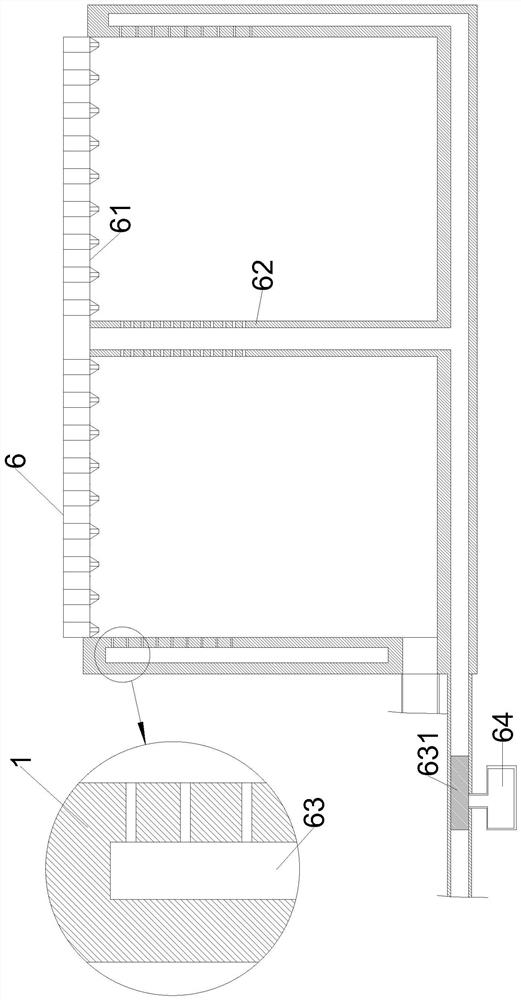

[0033] As a specific embodiment of the present invention, the oil removal unit 3 includes an oil screening pipe 31, an oil discharge pipe 32, and an oil storage tank 33. The inside of the oil screening pipe 31 is fixedly connected to an annular sieve plate 311, and the surface of the sieve plate 312 is provided with A water-oil separation membrane, a circular sieve plate 312 is fixedly connected to the nozzle at the lower end of the oil sieve pipe 31, and an oil-water separation membrane is provided on the surface of the sieve plate 312.

[0034] The waste water screened by the auger 22 and treated by the adsorbent enters the oil screen pipe 31 of the oil removal unit 3, and first passes through the water-oil separation membrane on the surface of the annular sieve plate 311 in the oil screen pipe 31. The water-oil separation membrane can allow oil to pass through the water Stop it, so that the oil in the waste water enters the inner edge of the oil screen pipe 31 through the wa...

specific Embodiment approach

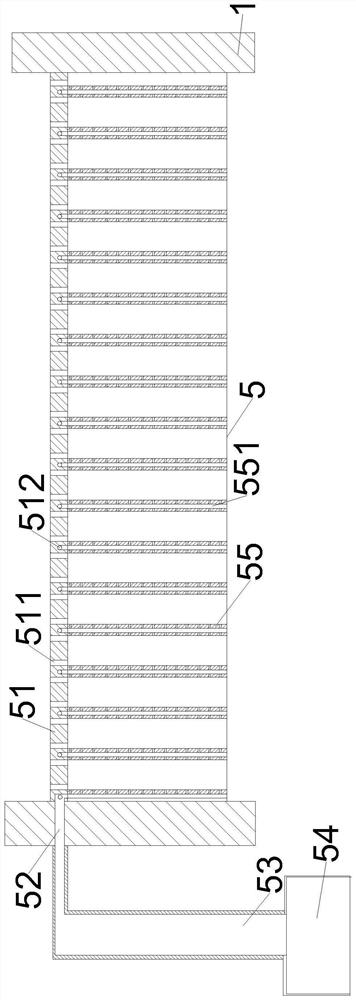

[0035] As a specific embodiment of the present invention, a plurality of down-flow boards 55 are fixedly connected between the two down-holes 511 on the lower surface of the down-water board 51 , and a steam ventilating slot communicated with the steam pipe groove 512 is provided in the middle of the down-water board 55 551, a plurality of steam outlets are evenly opened between the steam vent groove 551 and the outside of the water-shunting plate 55.

[0036] When the waste water flows down through the drain hole 511 on the drain plate 51, the waste water can flow down along the drain plate 55 by setting the drain plate 55, thereby forming a water curtain on the surface of the drain plate 55, and there is a steam pipe groove in the middle of the drain plate 55. 512 is connected to the steam tank 551, and the steam tank 551 sprays high-temperature steam through the steam outlet to contact the waste water for distillation; through the formation of the water curtain and the setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com