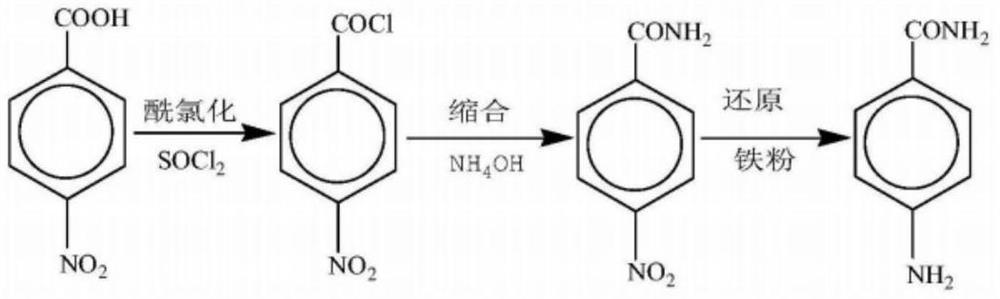

Production method of p-aminobenzamide

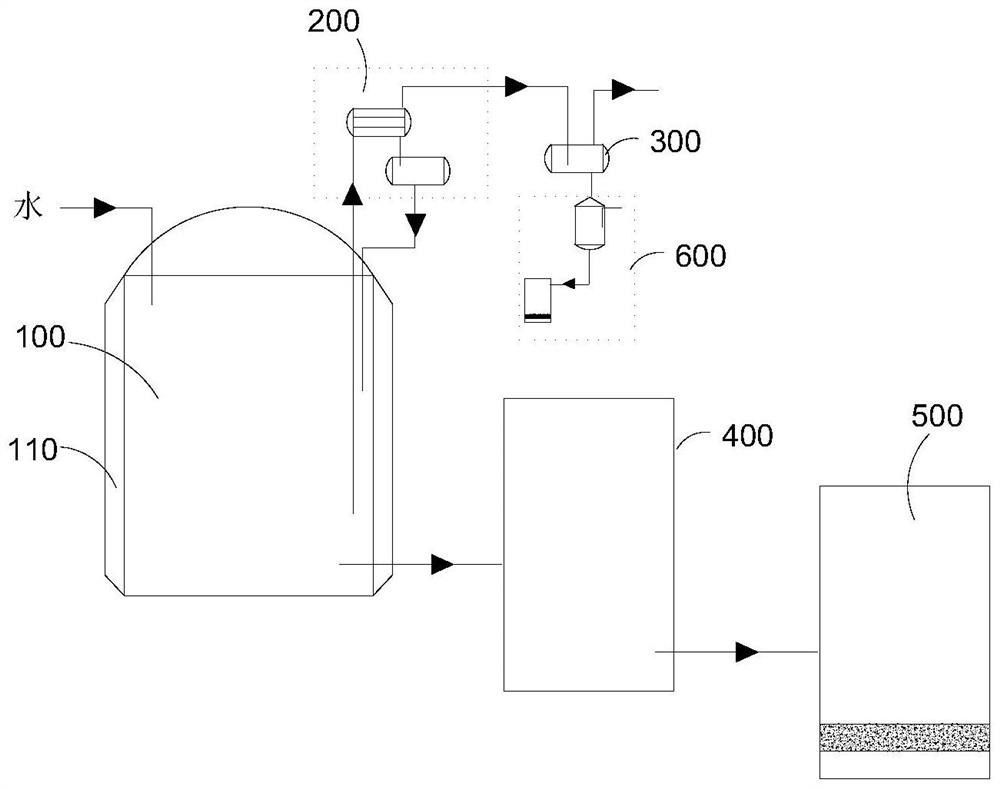

A technology of aminobenzamide and nitrobenzamide, which is applied in the production field of p-aminobenzamide, can solve the problems of high production cost, achieve the effects of reducing production cost, safe and reliable reaction process, and reducing separation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

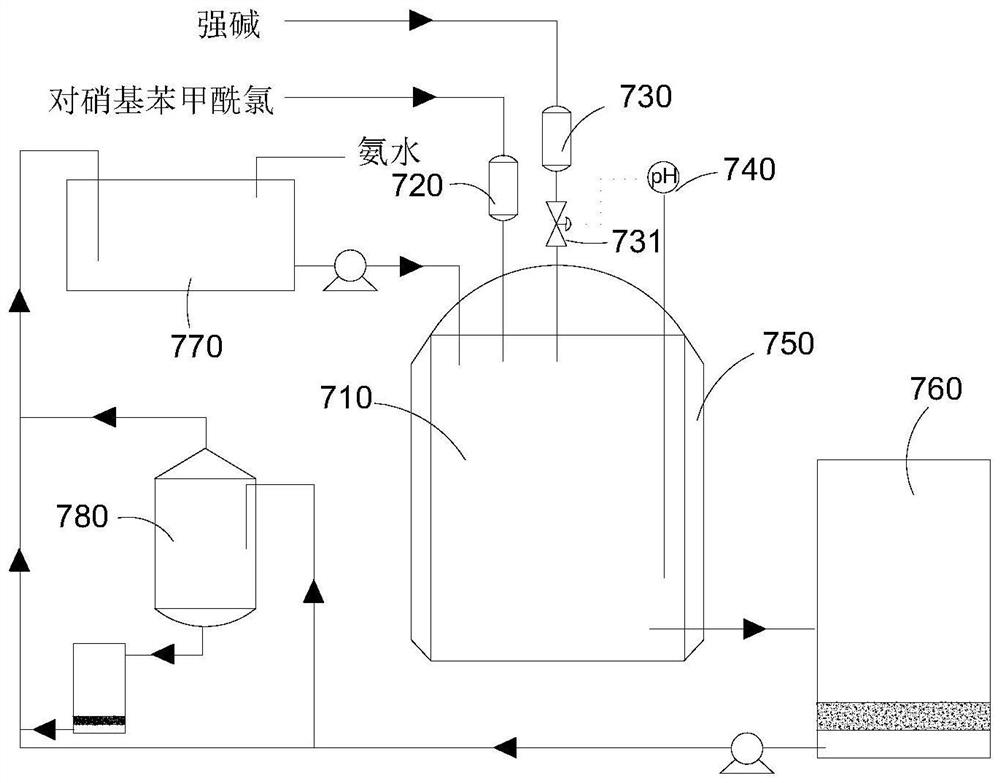

Method used

Image

Examples

experiment example 1

[0084] Configuration mass concentration is 10% ammonia solution, get 95g of this ammonia solution, add in the four-necked flask, be warmed up to 75 ℃, in the four-necked flask, drip the p-nitrobenzoyl chloride of melting, reduce to the pH value of reaction solution to below 10. In the four-necked flask, dropwise add 10% NaOH solution simultaneously, adjust the pH value of reaction solution respectively to be 8~9,9~10,10~11,11~12, drop 92.8g ( 0.5mol) of molten p-nitrobenzoyl chloride. The temperature of the reaction solution was raised to 85° C. and kept for 1 h. Cool down to room temperature, filter the feed liquid to obtain a mixture of solid p-nitrobenzamide and p-nitrobenzoyl chloride, the liquid is NaCl solution, and test the content of solid p-nitrobenzamide and p-nitrobenzoyl chloride , to test the ammonia nitrogen content of the NaCl solution, and the test results are shown in Table 1.

[0085] Table 1 Experimental Example 1 Test Results

[0086]

experiment example 2

[0088] Configure ammonia water mixed solution A. In ammonia water mixed solution A, the mass concentration of ammonia water is 10%, and the mass concentration of NaCl is 10%. Molten p-nitrobenzoyl chloride was added dropwise until the pH value of the reaction solution was lowered to below 10. In the four-necked flask, dropwise add 10% NaOH solution simultaneously, adjust the pH value of reaction solution respectively to be 8~9,9~10,10~11,11~12, drop 92.8g ( 0.5mol) of molten p-nitrobenzoyl chloride. The temperature of the reaction solution was raised to 85°C and kept for 2h. Cool down to room temperature, filter the feed liquid to obtain a mixture of solid p-nitrobenzamide and p-nitrobenzoyl chloride, the liquid is NaCl solution, and test the content of solid p-nitrobenzamide and p-nitrobenzoyl chloride , to test the ammonia nitrogen content of the NaCl solution, and the test results are shown in Table 2.

[0089] Table 2 Experimental Example 2 Test Results

[0090]

experiment example 3

[0092] Using the waste water generated in Experimental Example 2, a mixed solution of ammonia and water was prepared. In the mixed solution of ammonia and water, the mass concentration of ammonia was 10%. Take 95g of the aqueous ammonia solution, put it into a four-necked flask, raise the temperature to 80°C, and drop molten p-nitrobenzoyl chloride into the four-necked flask until the pH value of the reaction solution drops below 10. In the four-necked flask, dropwise add 10% NaOH solution simultaneously, adjust the pH value of reaction solution respectively to be 8~9,9~10,10~11,11~12, drop 92.8g ( 0.5mol) of molten p-nitrobenzoyl chloride. The temperature of the reaction solution was raised to 85°C and kept for 2h. Cool down to room temperature, filter the feed liquid to obtain a mixture of solid p-nitrobenzamide and p-nitrobenzoyl chloride, the liquid is NaCl solution, and test the content of solid p-nitrobenzamide and p-nitrobenzoyl chloride , to test the ammonia nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com