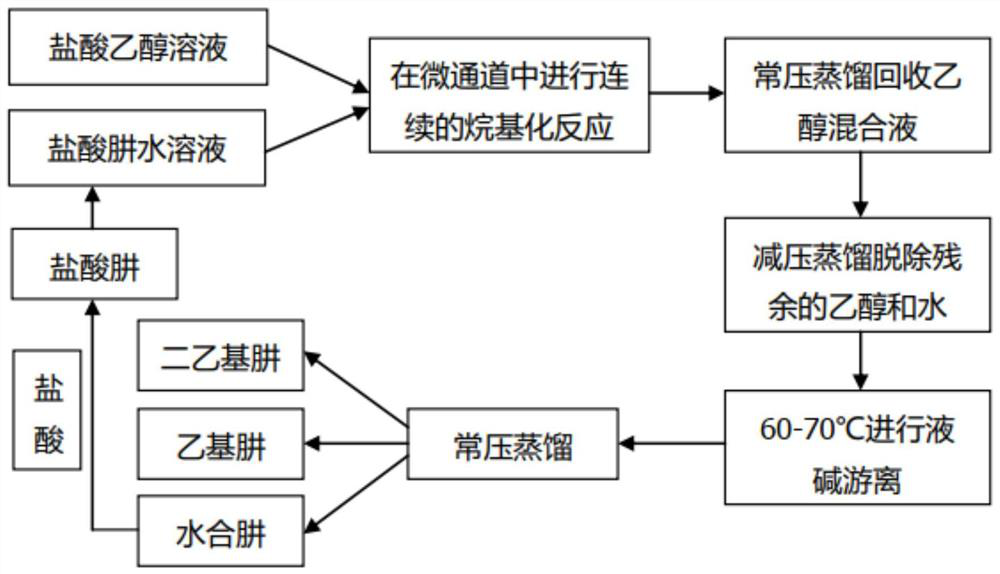

Method for preparing ethyl hydrazine through continuous flow of microreactor

A micro-reactor, micro-channel reactor technology, applied in chemical instruments and methods, hydrazine preparation, chemical/physical/physical-chemical reactors, etc., can solve the problems of difficult separation, inability to obtain pure ethyl hydrazine, etc. Generation of side reactions, high safety, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

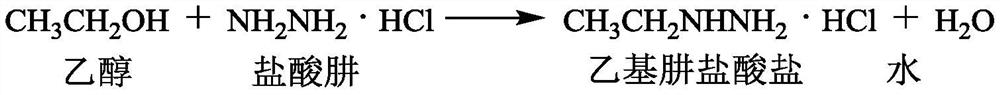

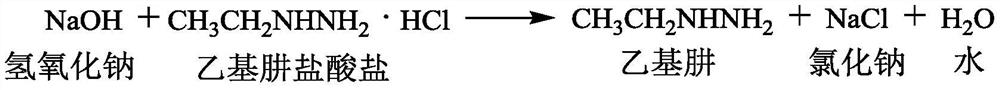

Method used

Image

Examples

Embodiment 1

[0045] (1) Hydrazine hydrochloride is mixed with water to prepare an aqueous solution of hydrazine hydrochloride so that the mass percent concentration of hydrazine hydrochloride is 75%, and ethanol is mixed with 30% aqueous hydrochloric acid to prepare ethanol hydrochloride so that the concentration of hydrochloric acid is 1%. ;

[0046] (2) send the ethanol hydrochloride solution into the microchannel of the microchannel reactor with a pump earlier, fill the microchannel, then use the pump to send the hydrazine hydrochloride aqueous solution into the microchannel, so that the hydrazine hydrochloride and ethanol are continuously reacted in the microchannel, Wherein, the reaction temperature is 102°C, the reaction pressure is 0.25MPa, the residence time is 70s, the molar ratio of ethanol and hydrazine hydrochloride is controlled to be 1.5:1, and the hydrazine hydrochloride aqueous solution is controlled to be sent into the microchannel under the condition of 50-60°C, so that th...

Embodiment 2

[0053] (1) Hydrazine hydrochloride is mixed with water to prepare an aqueous solution of hydrazine hydrochloride so that the mass percent concentration of hydrazine hydrochloride is 85%, and ethanol is mixed with 30% hydrochloric acid aqueous solution to prepare a hydrochloric acid ethanol solution so that the concentration of hydrochloric acid is 1%. ;

[0054] (2) send the ethanol hydrochloride solution into the microchannel of the microchannel reactor with a pump earlier, fill the microchannel, then use the pump to send the hydrazine hydrochloride aqueous solution into the microchannel, so that the hydrazine hydrochloride and ethanol are continuously reacted in the microchannel, Wherein, the reaction temperature is 105°C, the reaction pressure is 0.2MPa, the residence time is 60s, the molar ratio of ethanol and hydrazine hydrochloride is controlled to be 1.55:1, and the hydrazine hydrochloride aqueous solution is controlled to be sent into the microchannel at 50-60°C to make...

Embodiment 3

[0061] (1) Hydrazine hydrochloride is mixed with water, and the aqueous solution of hydrazine hydrochloride is prepared, so that the mass percentage concentration of hydrazine hydrochloride is 80%, and ethanol is mixed with the aqueous hydrochloric acid solution of 30% with concentration, and the hydrochloric acid ethanol solution is prepared, so that the mass percentage concentration of hydrochloric acid is 1%;

[0062] (2) send the ethanol hydrochloride solution into the microchannel of the microchannel reactor with a pump earlier, fill the microchannel, then use the pump to send the hydrazine hydrochloride aqueous solution into the microchannel, so that the hydrazine hydrochloride and ethanol are continuously reacted in the microchannel, Wherein the reaction temperature is 103°C, the reaction pressure is 0.2MPa, the residence time is 65s, the molar ratio of ethanol and hydrazine hydrochloride is controlled to be 1.5:1, and the hydrazine hydrochloride aqueous solution is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com