Early-strength water reducing agent containing phosphate monomer and preparation method of early-strength water reducing agent

An early-strength, water-reducing agent technology, which is applied in the field of construction admixtures, can solve the problems of the late strength of concrete, the impact of concrete fluidity, the impact of long-term mechanical properties of concrete, durability, and poor early-strength effects, and shorten the setting time. , early strength and other effects of high age strength and high water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

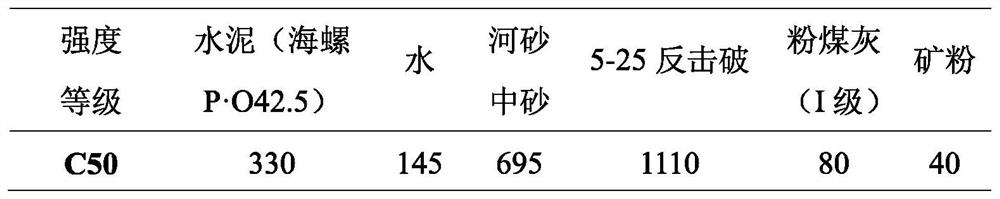

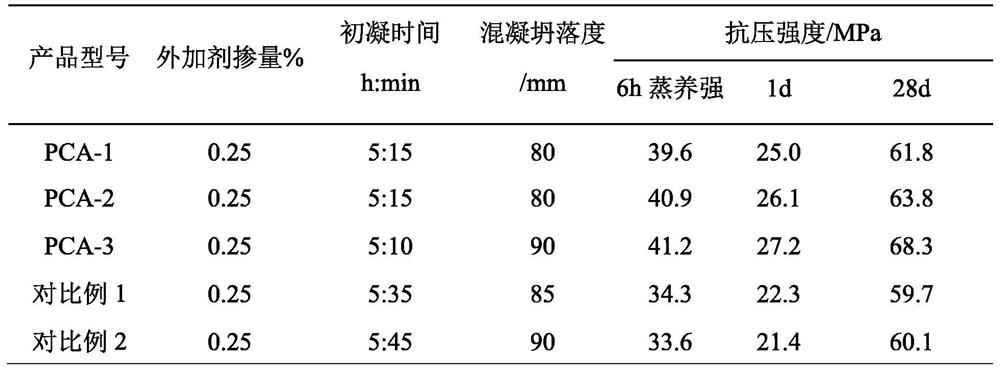

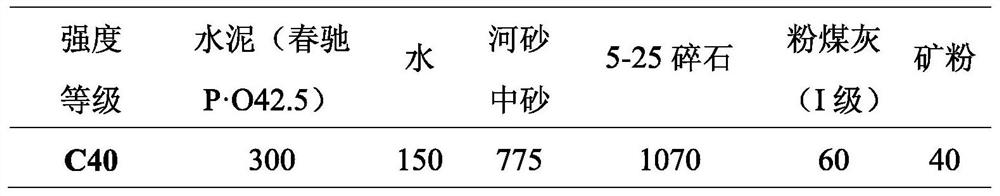

Examples

Embodiment 1

[0031] Preparation of unsaturated phosphate functional monomer: add 50 parts by weight of 2-methallyl alcohol and 105 parts by weight of phosphorus pentoxide into the reaction device, heat the temperature to 85-90°C, add 0.8 parts by weight of phosphotungsten Acid, keep warm for 4±1h to obtain unsaturated phosphate functional monomer;

[0032] Preparation of early-strength water reducer containing phosphate monomer:

[0033] (1) 200 parts by weight of HPEG4000 molecular weight macromonomer, 5 parts by weight of acrylamide, 1.5 parts by weight of ammonium persulfate, and 270 parts by weight of deionized water are put into the reactor device, and stirred to obtain a mixture;

[0034] (2) 25 parts by weight of unsaturated phosphate functional monomer, 3 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, and 15 parts by weight of deionized water are dropped into the dropping device, and mixed uniformly to obtain the first Drop feed;

[0035] (3) 0.5 parts by weight of...

Embodiment 2

[0039] Preparation of unsaturated phosphate functional monomer: add 50 parts by weight of 2-methallyl alcohol and 105 parts by weight of phosphorus pentoxide into the reaction device, heat the temperature to 85-90°C, add 1.3 parts by weight of phosphotungsten Acid, keep warm for 4±1h to obtain unsaturated phosphate functional monomer;

[0040] Preparation of early-strength water reducer containing phosphate monomer:

[0041] (1) Put 200 parts by weight of TPEG6000 molecular weight macromonomer, 8 parts by weight of acrylamide, 2.0 parts by weight of ammonium persulfate, and 280 parts by weight of deionized water into the reactor device, and stir to obtain a mixture;

[0042] (2) 25 parts by weight of unsaturated phosphate functional monomer, 5.5 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, and 20 parts by weight of deionized water are dropped into the dropping device, and mixed uniformly to obtain the first Drop feed;

[0043] (3) 0.5 parts by weight of vita...

Embodiment 3

[0047] Preparation of unsaturated phosphate functional monomer: Add 50 parts by weight of butenol and 75 parts by weight of phosphoric acid into the reaction device, heat the temperature to 85-90°C, add 1.0 parts by weight of phosphotungstic acid, and keep it warm for 4±1h. That is, the unsaturated phosphate ester functional monomer is obtained;

[0048] Preparation of early-strength water reducer containing phosphate monomer:

[0049] (1) Put 200 parts by weight of HPEG4000 molecular weight macromonomer, acrylamide of 6.5 parts by weight, 2.0 parts by weight of ammonium persulfate, and 280 parts by weight of deionized water into the reactor device, and stir to obtain a mixture;

[0050] (2) 30 parts by weight of unsaturated phosphate functional monomer, 3 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, and 20 parts by weight of deionized water are dropped into the dropping device, and mixed uniformly to obtain the first Drop feed;

[0051] (3) 0.68 parts by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com