Resourceful treatment method for hazardous waste in pharmaceutical industry

A technology for the pharmaceutical industry and treatment method, applied in chemical instruments and methods, treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems of acid corrosion of equipment, waste of resources, increase of denitration pressure, etc., and achieve zero discharge of hazardous waste, saving effect of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

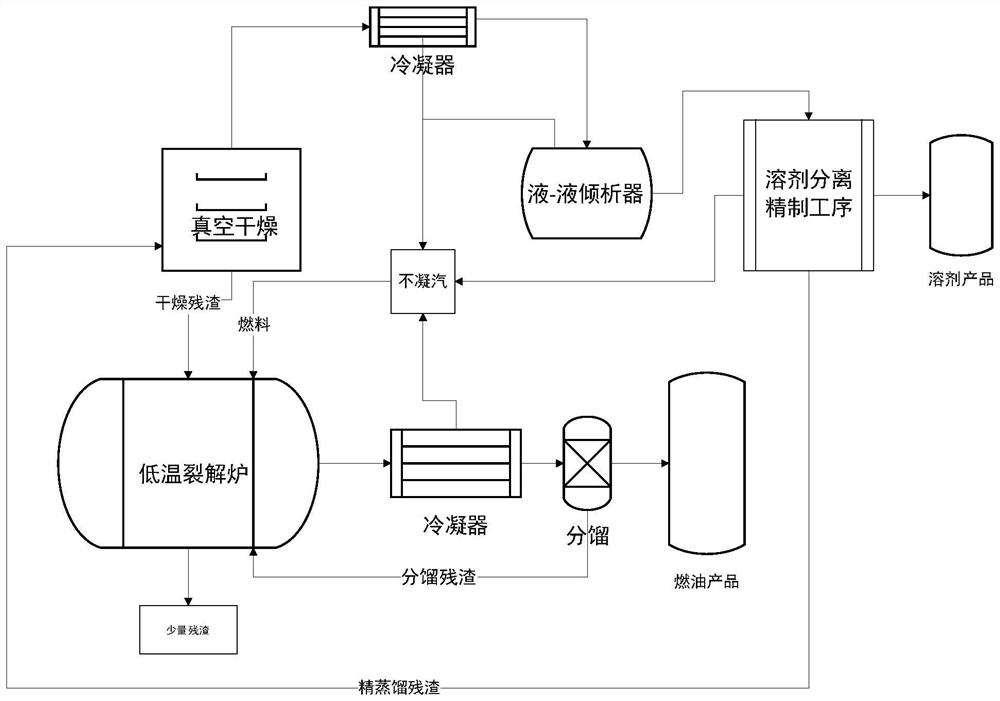

[0035] Such as figure 1 A resource treatment method for hazardous waste in the pharmaceutical industry is shown, comprising the following steps:

[0036] (1) Sampling and detection of distillation range. Determine the condensation condition of the condenser according to the initial boiling point temperature, determine the vacuum drying conditions (vacuum degree, drying temperature) according to the distillation range range, and determine the processing capacity of low-temperature cracking according to the residue content.

[0037] (2) Send the fine distillation still residue and centrifuged mother liquor in the pharmaceutical industry to a vacuum dryer for drying.

[0038] (3) After the vaporized material obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com