Novel adhesive for disc pelletizing sintered pellets and preparation method of novel adhesive

A new type of binder and disc pelletizing technology, applied in the field of disc pelletizing sintering pellet new binder, disc pelletizing sintering pellet new binder and its preparation field, can solve the problem of reducing pellets Problems such as pellet reducibility, lower pellet grade, and poor pellet quality can achieve the effect of reducing smelting slag rate, reducing heat consumption, and less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A new type of binder for disc pelletized sintered pellets, including: calcium oxide, magnesium oxide, tackifier, water reducer, organic high molecular polymer, the new binder for disc pelletized sintered pellets The agent is calculated by mass percentage: calcium oxide 40-52%, magnesium oxide 3-10%, tackifier 3-5%, water reducing agent 8-12%, organic high molecular polymer 33-38%, the organic The high-molecular polymer is set as a water-soluble organic high-molecular polymer, and the organic high-molecular polymer becomes a high-viscosity liquid when it meets water;

[0030] In terms of parts by mass, the formula of the novel binder for disc pelletizing and sintering pellets is as follows: 48% calcium oxide, 5% magnesium oxide, 3% tackifier, 9% water reducer, organic polymer Polymer 35%.

[0031] The addition ratio of described disc pelletizing and sintering pellets new binder is set to 1-2% when used, and the optimal addition ratio when using disc pelletizing and sint...

Embodiment 2

[0042]The difference from Example 1 is that, in terms of mass percentage, the formula of the novel binder for disc pelletizing and sintering pellets is as follows: 40% calcium oxide, 3% magnesium oxide, 4% tackifier, water reducing Agent 8%, organic polymer 33%;

[0043] A new type of binder for disc pelletizing and sintering pellets and a preparation method thereof, comprising the following steps:

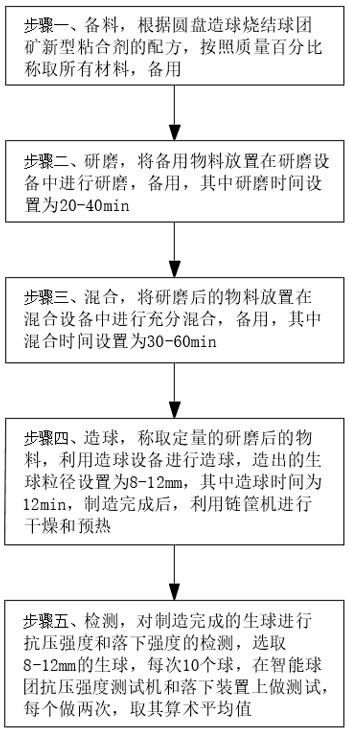

[0044] Step 1. Prepare materials. According to the formula of the new binder of disc pelletizing and sintering pellets, all materials are weighed according to the mass percentage and set aside;

[0045] Step 2: Grinding, placing the spare material in the grinding equipment for grinding, and setting it aside, wherein the grinding time is set to 20 minutes;

[0046] Step 3, mixing, place the ground material in the mixing equipment for full mixing, and set it aside for later use, and the mixing time is set to 30 minutes;

[0047] Step 4: Make pellets. Weigh the quantitatively groun...

Embodiment 3

[0050] The difference from Example 1 is that, in terms of parts by mass, the formula of the novel binder for disc pelletizing and sintering pellets is specifically as follows: calcium oxide 52%, magnesium oxide 10%, tackifier 5%, reducing Water agent 12%, organic polymer 38%;

[0051] A new type of binder for disc pelletizing and sintering pellets and a preparation method thereof, comprising the following steps:

[0052] Step 1. Prepare materials. According to the formula of the new binder of disc pelletizing and sintering pellets, all materials are weighed according to the mass percentage and set aside;

[0053] Step 2. Grinding. Place the spare materials in the grinding equipment for grinding, and set the grinding time to 40 minutes;

[0054] Step 3, mixing, place the ground material in the mixing equipment for full mixing, and set it aside for later use, wherein the mixing time is set to 60 minutes;

[0055] Step 4: Make pellets. Weigh the quantitatively ground materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| burst temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com