High-capacity graphite negative electrode material and preparation method and application thereof

A graphite negative electrode and high-capacity technology, which is applied in the field of negative electrode materials, can solve the problems of capacity attenuation, lower charge and discharge efficiency, and damage to the natural graphite structure, and achieve the effects of preventing contact, improving rate performance, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

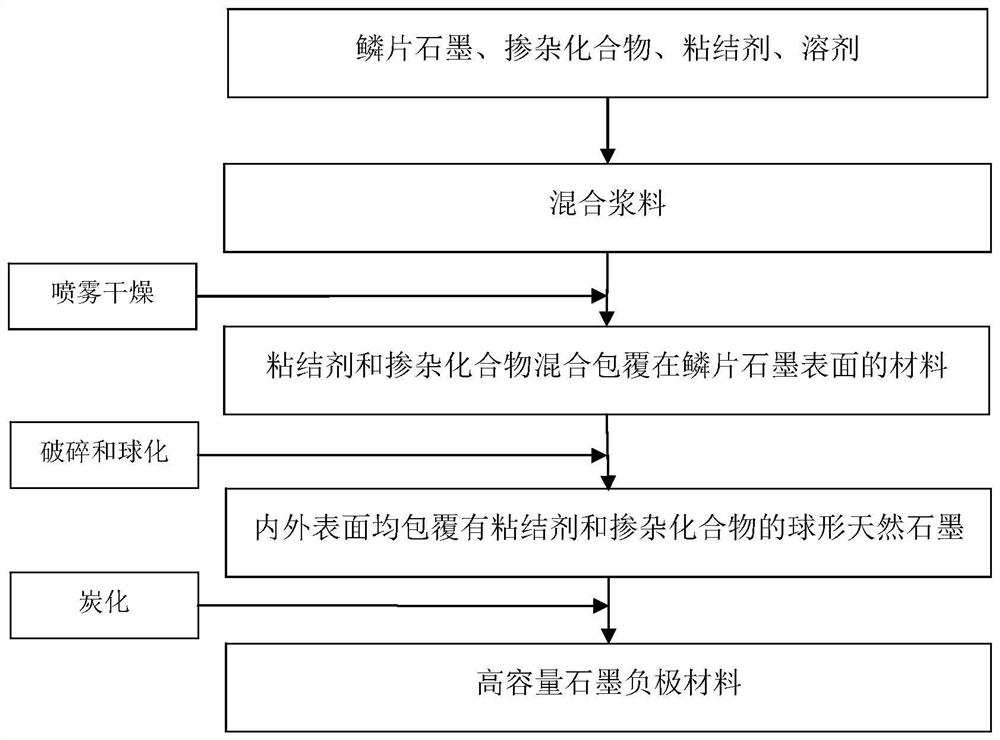

[0030] A kind of preparation method of high-capacity graphite negative electrode material, its preparation flow chart is as follows figure 1 shown, including the following steps:

[0031] (1) According to the mass ratio of flake graphite, doping compound and binding agent is 80:5:15, flake graphite, phosphoric acid (doping compound) and coal tar pitch (binding agent) with an average particle size of 35 μm are added to acetone , control the solid content to 15%, fully stir and sonicate to obtain a mixed slurry.

[0032] (2) The mixed slurry obtained in step (1) is spray-dried to obtain a material in which coal tar pitch and phosphoric acid are mixed and coated on the surface of graphite flakes, that is, the binding agent of the present invention and a doping compound are mixed and coated on graphite flakes Surface material.

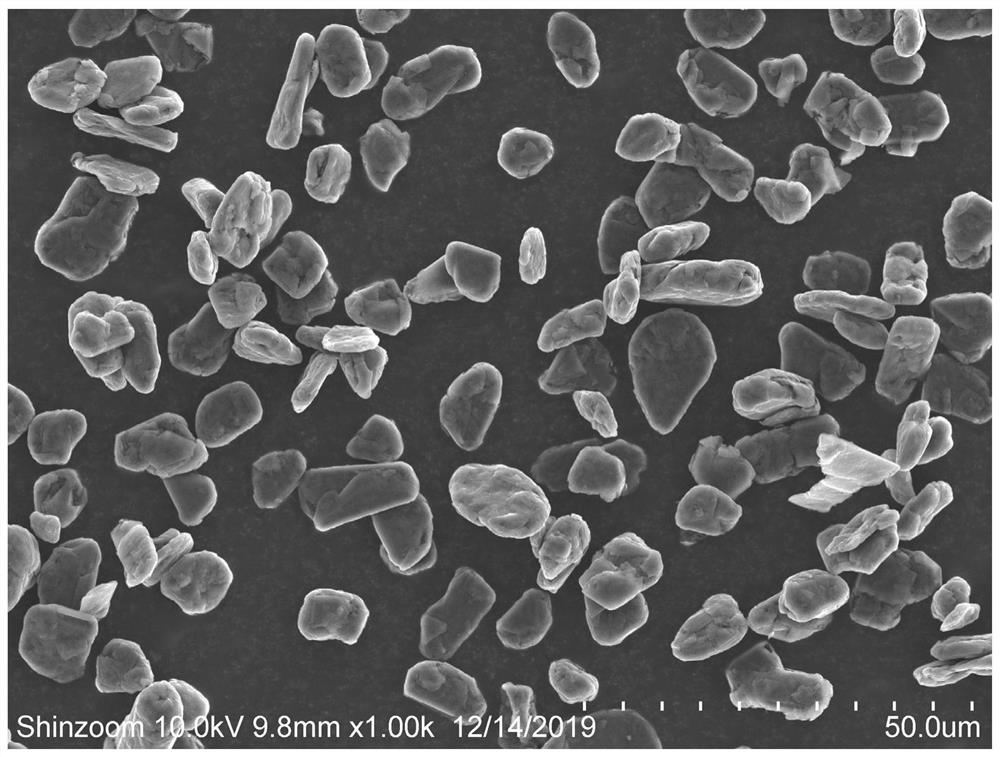

[0033](3) The coal tar pitch obtained in step (2) and phosphoric acid are mixed and coated on the surface of graphite flakes and crushed, so that each g...

Embodiment 2

[0060] A preparation method of a high-capacity graphite negative electrode material is basically the same as that of Example 1, the only difference being that in the step (1) of Example 2, the solid content of the mixed slurry is 1%.

[0061] The high-capacity graphite negative electrode material prepared in Example 2 was made into a button battery and a full battery according to the method in Example 1, and the electrochemical performance results are shown in Table 1.

Embodiment 3

[0063] A preparation method of a high-capacity graphite negative electrode material is basically the same as that of Example 1, the only difference being that in the step (1) of Example 3, the solid content of the mixed slurry is 5%.

[0064] The high-capacity graphite negative electrode material prepared in Example 3 was made into a button battery and a full battery according to the method in Example 1, and the electrochemical performance results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Charge and discharge rate | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com